Pu Polyurethane Sandwich Panel for insulated panels price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pu Polyurethane Sandwich Panel for insulated panels price

PU Sandwich Panel advantages

1. Effective insulation

The thermal conductivity coefficient of the rigid polyurethane(PU) foam can be 0.018-0.024 w/(m*k), which is only the half of expanded polystyrene(EPS), if its density is 38-42kg/m³. Rigid polyurethane foam is the best organic insulating material.

Since the thermal conductivity coefficient of the vesicant used is much lower than air, the insulating property of rigid polyurethane foam is better than rock wool, glass wool, expanded polystyrene and extruded polystyrene. Moreover, its insulating property can be sustainable for more than 30 years for its special closed-cell structure and resistance to gas diffusion.

2. Excellent corrosion and weather resistance

The polyurethane foam performs well in corrosion and weather resistance for its closed-cell structure and its surface material.

3. Moisture proof and waterproof

4. Anti freeze-thaw and sound absorption

The rigid polyurethane foam also performs well in anti freeze-thaw and sound absorption.

5. Energy efficiency and cost saving

Although the price is much higher than other alternatives, taking into account the excellent insulating property of the polyurethane foam, the increased costs will be offset by a substantial reduction in heating and cooling costs. Furthermore, we can reduce the thickness of external structure of the building by using thinner polyurethane foam to achieve the same insulating requirements, thereby increasing the indoor area.

6. Fireproof and high temperature resistance

Rigid polyurethane foam is a flame-retardant and self-extinguishing material after. It can reach a softening point of 250 degrees Celsius and decomposes at a higher temperature. A layer of carbon will be formed if it is lighted, which will effectively prevent the spread of the flame.

7. Anti-deformation and hardly to be cracked

The average life expectancy of rigid polyurethane foam can be more than 30 years under normal use and maintenance. It won’t be destroyed by fungi and algae growth, or rodents.

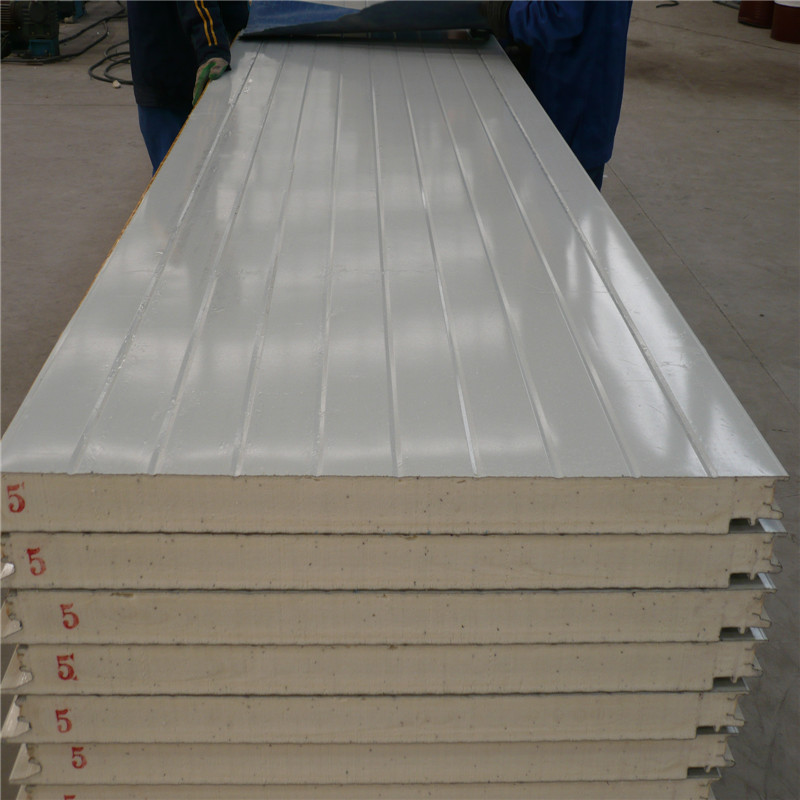

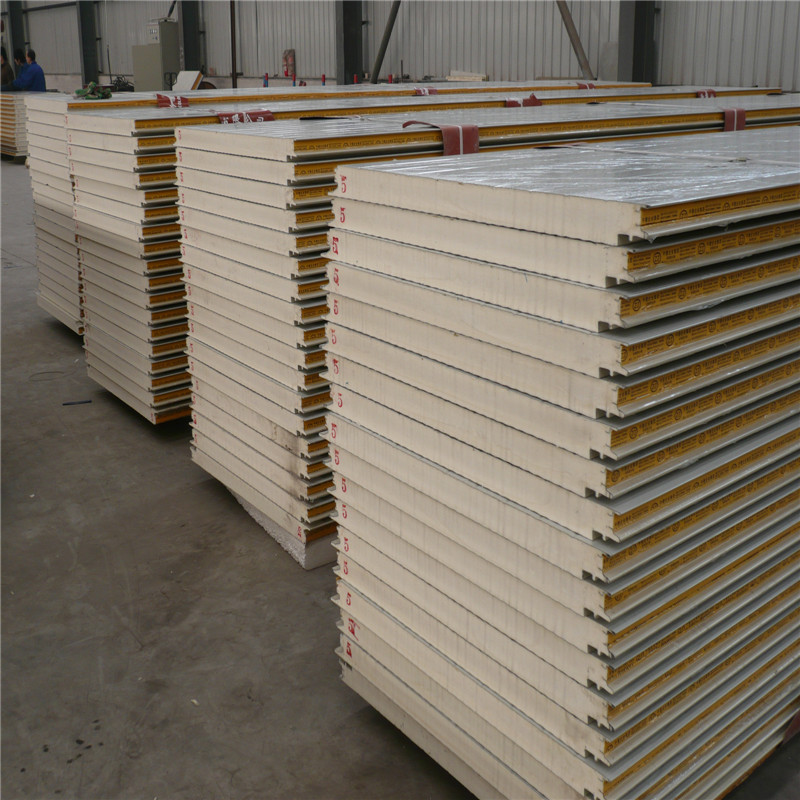

8. Beautiful appearance and easy installation

The polyurethane foam can be bonded with different surface materials, such as color steel plates, cement fiberglass cloth, aluminum, stainless steel and so on. So there are a lot of beautiful appearances and structures for customers’ choice according to their different specific requirements. It can be easily installed with fasteners because it is prefabricated in factory, which will significantly reduce the cost and shorten the schedule of construction.

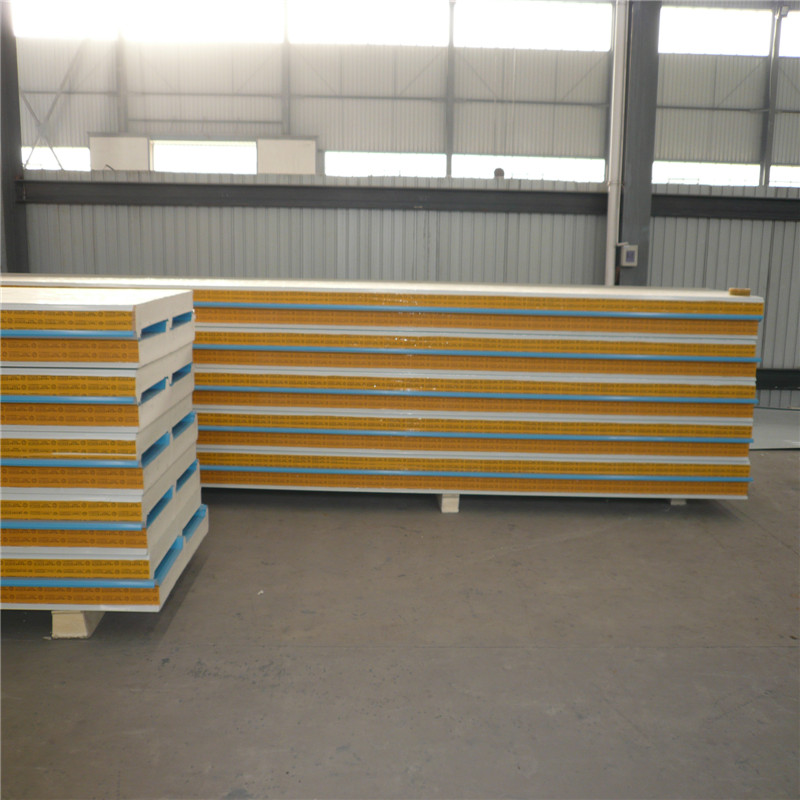

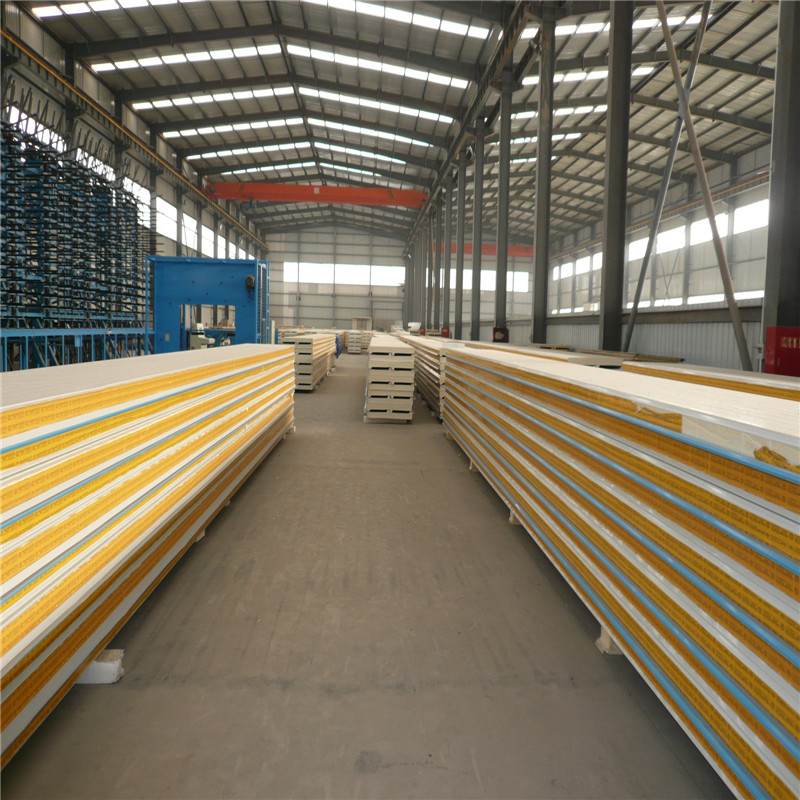

PU sandwich panels workshop

- Q:How to use the 0.3x50 sandwich panel to do a hundred square meters of roof to install how much money? Guanzhong area.

- With a color coated steel plate, rust does not solve the problem.

- Q:in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q:I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- You will need to use surface mount materials that can be screwed or bolted to the sandwich panels. Most electrical distribution centers have surface mounting options. For wiring, you will need to use conduit (PVC, EMT, or flex), metal clad cable, or wire mold. Surface mount junction boxes for devices need to be compatible with your choice of wiring method.

- Q:There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. The burning performance of the material does not meet the requirements of Grade II refractory grade building. Replacement material ~ ~

- Q:Steel structure plant color steel sandwich panel roof design fire resistance 0.5H, need to apply fire retardant paint

- Steel structure color steel sandwich panel fire for 0.5 hours, if it is required to color steel fire board is 0.5 hours, then you must do fire paint, choose a thin fire paint more cost-effective, cheap. If it is required to color steel plate in the sandwich material to 0.5 hours, then you choose the appropriate sandwich material, such as rock wool made of sandwich materials.

- Q:Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Yes, EPS is glass steel surface, color steel sandwich board is color steel surface, EPS expensive, the difference is about 100 per meter

- Q:50mm thick roof color steel sandwich board price is generally how much money a m2?

- 50mm thick roof sandwich board is generally 65 yuan per square main to see how thick you want the steel plate

- Q:Will the Yanmian sandwich color steel plate of the plant can reach the fire two grade requirements?

- Yanmian sandwich color of the core material is basalt and other natural ore as the main raw material, the high temperature melt into the fiber, adding the right amount of binder, curing and made. Is the same type (sandwich panel series) in the fire resistance of the strongest of a new type of fire board. Applicable to drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 80 minutes. Some information on "with 600 ℃ fire resistance, fire rating to A level."

- Q:What are the black glue used in industrial production of sandwich panels? Chemical properties What chemicals are soluble in chemical reagents?

- Two-component polyurethane black and white plastic A component: B part of the white part of white polyester, black special polyester. Specific components are unknown, there are differences between manufacturers. Soluble in ethyl acetate.

- Q:I am in OKorder because of procurement needs, would like to first understand the color steel factory in OKorder which manufacturers quality and cheap products! Worthy of lazy thanks!

- OKorder Bo Xing color steel company specializing in the production of rock wool sandwich panels, fire, waterproof performance is very good, the supply of a lot of large steel company, you are welcome to call us, absolutely high quality and cheap

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pu Polyurethane Sandwich Panel for insulated panels price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords