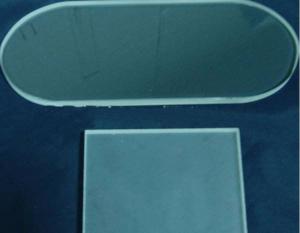

Optical Quartz Glass Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.material: Quartz

2.size: any size

3.useful:semiconductor,chemical industry,etc

4..corrosion resistance

Material

Quartz glass

Purity :

More than 99.99%

Efforts

1.tolerance control (min:±0.1)

2.accurate dimension according to customer's request

3.complete after-service systerm

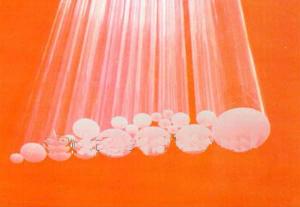

Diameter:1.3-350mm Thickness:0.6-10mm (on the basis of the buyer's request)

Further-processing:

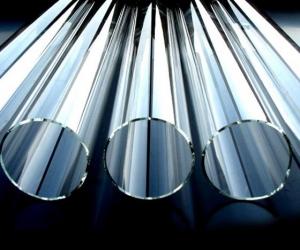

Ends closing, sand blasting, polishing, bending, cutting, pinching, burning mouth and so on

The special one, pls kindly send me the drwaing

Application:

Widely used in the filed of semiconductor, metallurgy, chemical industry, electric light source, photo-communication, medical equipment, scientific instruments and so on.

we really appreciate your visiting and assisting,pls kindly tell me your sizes and technology.

Properties | |||

Density | Elastic modulus | Tensile strength | Hardness |

2.2g/cm3 | 700*103kg/cm3 | .-500kg/cm3 | 5.5-6.5 |

- Q:What is the optimum ultrasonic frequency for ultrasonic cleaning of silicon wafers?

- Ultrasonic cleaning machine of silicon wafer method and its device will be washing method is placed in the bottom horizontal grinding silicon wafer cleaning groove above the fence shaped quartz rod frame, in order to ensure the cleaning tank with deionized water height and the constant flow conditions, cleaning by ultrasonic vibrator is arranged on the bottom of the cleaning tank, the ultrasonic frequency is 40KHz. 80KHZ, every 5 minutes will turn a grinding silicon wafer surface grinding of silicon surface to be super super continuous wash wash no black smoke pollutants check.

- Q:The working principle of quartz tube heater

- Far infrared heating tube is used by the opal quartz glass tube, with special processing of resistance alloy material as a heating element, the opal quartz glass can be absorbed into the electric wire from radiation almost all of the visible light and near infrared light, and can make the far infrared radiation. But the current industrial infrared heating tube basically eliminates the milky white quartz tube, because of its relatively brittle material, it can not form a very long white heating tube. The milky white has an anti - light effect that stops its heat. Because of its high wall temperature, it is only suitable for near infrared heating.

- Q:What can be used after battery recycling?

- Use of waste battery recycling: discarded batteries, the zinc shell is only a small part of the loss, manganese dioxide is only a starting point oxidation, carbon powder, quartz rods and copper is far from being consumed. If it can be recycled and used, it will have very good economic and social benefits.

- Q:Indoor cable heat shrinkable tube is fiber heat shrinkable tubes do

- The transparent outer layer facilitates the detection of optical fiber joint connection is correct, the fiber can safe and easy to assemble, the contraction can keep the optical transmission characteristics of optical fiber, optical fiber joint to provide strength and protection, to avoid damage to the fiber during the installation process.

- Q:What is crystal powder?

- Crystal powder has high content of SiO2 and low impurity content. It can be used as raw material of optical fiber, quartz glass, quartz tube, quartz rod and quartz crucible. It is used in optical communication, lighting and semiconductor industries.

- Q:Characteristics and characteristics of ultra high temperature filter media

- Chemical vapor reaction (CVR) method. It is using B2O3 as the raw material by melt spinning is made of B2O3 heating low concentration ammonia, ammonia and ammonia to generate B2O3 boron reaction intermediate compounds, then the crystal type of unstable fiber under tension further in the mixed gas ammonia or ammonia and nitrogen in heating to 1800 DEG C, which is converted to BN fiber, its strength can be as high as 2.1GPa, modulus 345GPa.Chemical vapor deposition (CVD) method. The boron fiber is heated to 560 DEG C for oxidation at first. Then the oxidized fiber is heated to 1000-1400 DEG C in ammonia, and the BN fiber can be obtained by reaction about 6h.Organic precursor method. The fibers are made from a spinning process made from poly (urethane), which is crosslinked to produce non - melt fibers, which are then cleaved into fibers.

- Q:Is quartz wool insulation material?

- Method: (1) a quartz rod or tube oxyhydrogen flame melt drawing, then the oxyhydrogen blowpipe blowing, made of a diameter of 0.7 ~ 1 m quartz wool; (2) the flame melting quartz with high speed airflow form short fiber and mat; (3) the quartz wires or rods at a constant speed the oxyhydrogen flame or gas flame, high speed after softening into a longwire.

- Q:What is an optical fiber heat shrinkable tube used for?

- The heat shrinkable tube is composed of a transparent heat shrinkable tube, a hot melt pipe and a stainless steel needle (or ceramic rod / quartz rod).

- Q:The difference between quartz fiber and high silica fiber

- High silica fiber compared with quartz fiber, raw materials, low production cost, simple preparation process, but because of high silica fiber is a kind of porous fiber, the tensile strength is low, easy to absorb moisture, and temperature resistance is low compared with quartz fibre

- Q:Fiber core and cladding are not roundness, which is used to describe the parameters of optical fiber

- The crystal powder is Japanese jelly powder, crystal powder mainly composed of carrageenan, sodium alginate, agar gel and pectin gel plant compound and into, can slowly dissolve in cold water, soluble in hot water.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 2005 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 20.00% Eastern Europe 15.00% Southeast Asia 10.00% Central America 10.00% North America 10.00% Mid East 10.00% Western Europe 5.00% Northern Europe 5.00% Southern Europe 5.00% South America 5.00% South Asia 5.00% Domestic Market |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-9000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao,Shanghai,Lianyungang |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Korean |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Optical Quartz Glass Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords