Microporous Insulation Board 0.035W/m.k Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Conductive Microporous Insulation Board (0.035W/m.k)

Product Description:

CMDS Microporous Insulation Board is a microporous technology product, and is made up of a specific blend of filament reinforced fumed silica, which provides superb thermal performance.

It is an ideal back & shy insulation for various industries where high temperatures are needed, or extended exposure to 1150°C.

STD can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Main Product Features:

· Extremely low thermal conductivity

· High thermal stability

· High thermal stability

· Environment protection

· Easy to handle

· No harmful inhalable fibers

· Resist most chemical attacks

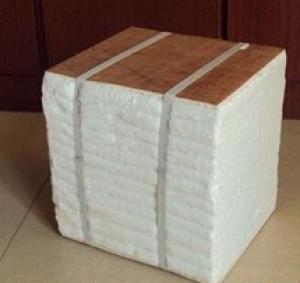

Products Images:

Products Specifications:

Minimum Order Quantity: | 1200 pc | Unit: | Pc | Loading Port: | Shanghai |

Supply Ability: | 20000 pc/month | Payment Terms: | TT or LC | Package: | Pallet |

Product Applications:

Industrial furnaces, fuel cells (SOFC), thermal batteries, Aluminum industry (smelters), glass & ceramics industry, petrochemical industry (cracking furnace, reformer)

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30% T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

- Q:What is the maximum temperature at which the glass is cured?

- The softening point of quartz glass is 1600 degrees, it is sodium phosphate and phosphate. Gas burner 1300 degrees, after homogenization processing, after annealing treatment of glass products.

- Q:What is the main role of fly ash added in concrete products?

- The rational use of fly ash in concrete, not only can replace part of cement, reduce the construction cost, but also because of its unique properties can be effectively used for the various requirements of the use of concrete, improve and enhance the performance of concrete.

- Q:What is the difference between calcium silicate board and cement fiber board?

- The common point between fiber cement pressure plate and calcium silicate board1, both of the raw materials are similar in composition, both contain silica fume, calcium and fiber.2. Both are processed by pulping and molding.3, the appearance, shape and length and width of the two specifications are basically the same.4, there are many overlapping areas in the scope of use, such as internal and external walls.

- Q:What are the exterior walls of the building besides the benzene board and the extruded board?

- Calcium silicate insulation insulation materials in 1980s has been recognized as the massive rigid insulation materials in one of the best, which is characterized by low density, high heat resistance, low thermal conductivity, flexural strength, high compressive strength, low shrinkage. But after entering 1990s, the promotion of the use of a downturn, the main reason is that many manufacturers to adopt in order to solve the problem of non asbestos fiber pulp, pulp fiber and not due to high temperature, thus affecting the thermal insulation material of high temperature resistance and increase the breaking rate, and not the economy.

- Q:What is the best price for the use of calcium silicate ceiling?

- Water will melt or become yellow, mildew. So if you choose their ceiling, you must first deal with the roof leak. Calcium silicate board with artificial and material prices of about 22 square meters, mainly for office space, and residential corridors and other public places decoration. Integrated ceiling is not afraid of water.

- Q:What's the use of white portland cement?

- The typical feature of white cement is high whiteness, with bright color, generally used for a variety of architectural decoration materials, painting, sculpture, a typical floor, terrazzo, white cement can be used to produce white and colored concrete, is the largest cement production decoration.

- Q:What are the production methods of calcium silicate board material?

- The synthesis process of dynamic method is carried out under stirring, the synthesis temperature is higher than the static process, and under the compression condition. The dynamic method is simple, no gel chemical order, products made of small capacity, good performance, can obtain high temperature (1000 degrees Celsius) of xonotlite products and ultra light products, but the need for high pressure vessel with stirring device, equipment and process condition requires high energy consumption and investment are higher. At present, this method is adopted abroad.

- Q:What are the main use of lime?

- Lime milk and mortar, slaked lime or lime paste, with lots of paint. Lime mortar or slaked lime powder can be used to prepare lime mortar or cement lime mixture mortar for masonry or plastering engineering.

- Q:What are the raw materials of cement products? What's the function?

- Water is necessary for the production of cement products, the role of water is to cement hydration. Generally, the water cement ratio of concrete is 0.40~0.65. If the water is too large, it will leave a hole in the concrete, which will affect the strength, density and durability of the concrete and even cause water leakage.

- Q:Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- Aitken is a brand of non asbestos calcium silicate board is a product name

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Insulation Board 0.035W/m.k Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords