Max Loading Capacity 16T Tower crane TC7135

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

Tower crane is used to lift building material such as concrete, steel bars vertically and horizonally.

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the crane.

2. The base connects to the mast (or tower), which gives the tower crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-gear and motor) that allows the

crane to rotate.

4. Attached to the slewing unit is the jib (or boom), the machinery arm, the counterweights

and, the Operators cabin

Features:

Type hammer head

Max loading capacity: 16t

Tip loading:3.5t

Jib length:71m

Free standing height:50m

Mast section: 2mx2mx3m

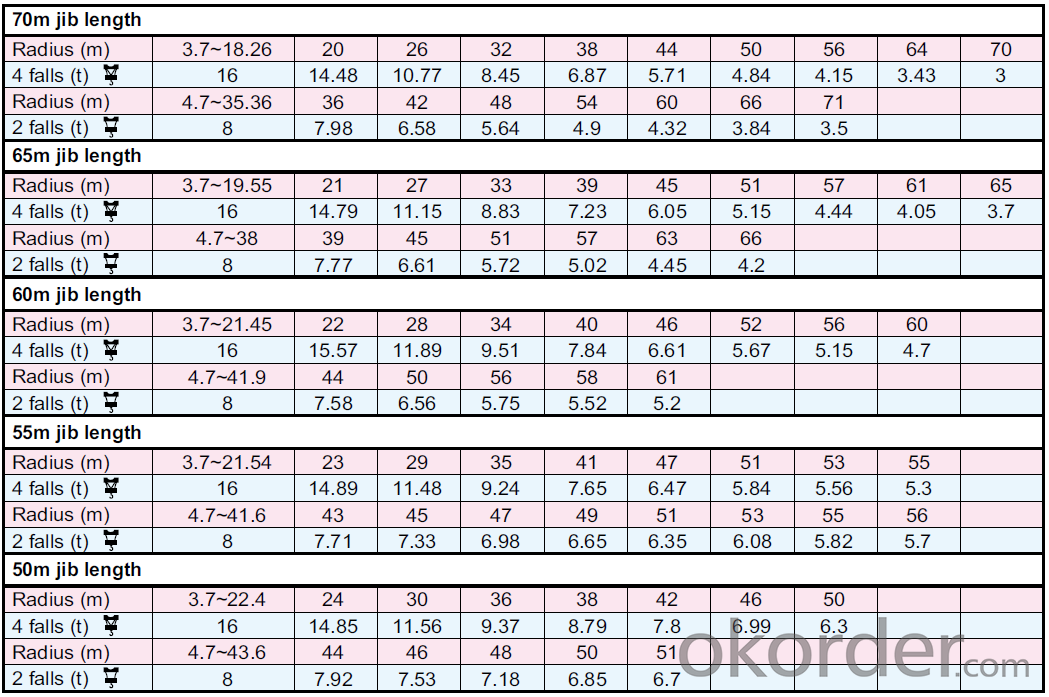

Loading Diagram:

FAQ

1. The foundation type available: fixed, undercarriage, travelling type

2. The life time of tower cranes: usually 10 years

3. Packaging:each unit needs 6x40HQ for free standing height

4. Shipping time: Usually around 35 days after receipt of advance payment

5. Payment term: TT, L/C

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q:This poor little guy has been out on my balcony where I smoke my cigarettes for two days now. One wing is badly mangled and he can't fly away, I thought to just let him work it out yesterday in hopes of him healing on his own somewhere, but today he was climbing on my leg as if asking for help and I feel horrible for him now...he's suffering, he hasn't gone far in at least 24 hours I feel I should feed him and give him water until he heals...what do crane flies even eat?? Any advise aside of killing him and putting him out of his misery would be great!!

- Well, it looks like they only have a lifespan of a 2 weeks at the most, so I'd just make him comfortable and let nature do its thing. According to Wikipedia, adult crane flies don't really eat--they just hang out and mate... If you really want, I suppose you could put some sugar water in a bottle cap or something for him.

- Q:my friend is in the hospital with really bad burns

- A really long string. Or have I misunderstood the question?

- Q:Is there a world record for making paper cranes?

- Yes! To commemorate the fiftieth anniversary of the dropping of the atom bomb on Hiroshima, two hundred thousand folded paper cranes were completed by December 15th 1995. Each crane had someone's name and peace message written on it. The intention is to preserve them to hand on to the 21st century. The event was sponsored by the Hiroshima International Cultural Foundation. There are other cool facts at the website below like the world's largest paper crane, most cranes in one hour, etc.

- Q:Tower crane attached concrete pump can be? Are there any state regulations?

- The state expressly states that it is not possible to have serious safety incidents in Hunan and Zhuzhou before

- Q:Is boom truck a crane truck? Are they the same or two different kind of truck?

- they are basically the same except a boom truck usually has a trailer and is used to haul things like limber or roof trusses

- Q:Has anyone made 1000 origami cranes and made a wish? Just wondering

- Yes. Also, after the atomic bombs were dropped on Japan, a girl with radiation poisoning tried it, but died after making six hundred and odd cranes. Make of that what you will.

- Q:Hi there!I was planning on making an electromagnetic crane, and I already understand how the electromagnet works. Its for the science fair in two weeks, but they asked us to make our projects soon.But I not sure hot to build the crane itself, any ideas?

- Here are literally thousands of organized woodworking projects in a members area and all you have to do is get them off your computer any time you want.

- Q:In the Legend of Sleepy Hollow Ichabod Crane has come from?

- In 1799, young constable Ichabod Crane is sent from New York City, New York to the fledgling settlement of Sleepy Hollow to investigate a series of ghoulish murders.

- Q:The Wayfarerby Stephen Crane The wayfarer, Perceiving the pathway to truth, Was struck with astonishment. It was thickly overgrown with weeds. Ha, he said, I see that none has passed here In a long time. Later he saw that each weed Was a singular knife. Well, he mumbled at last, Doubtless there are other roads.I understand that it is about a person taken the easy way out, but what other underlying meanings are there?

- A Wayfarer is an aimless wanderer. It's often more comfortable and flattering to the ego to think about a goal rather than to have the conviction to actually go through with achieving it. It's painfully difficult and takes a lot of strength to create your own path in life. People like to talk about how great they are, but ultimately, when faced with the truth they will opt to go along with the crowd.

- Q:If a friend folded a thousand paper cranes for you what would you think?

- that they must have a lot of time:)god bless

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Max Loading Capacity 16T Tower crane TC7135

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords