Loop Tie Wire/ Binding Wire with Good Quality Factory Direct Lower Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Looped Tie Wire Description:

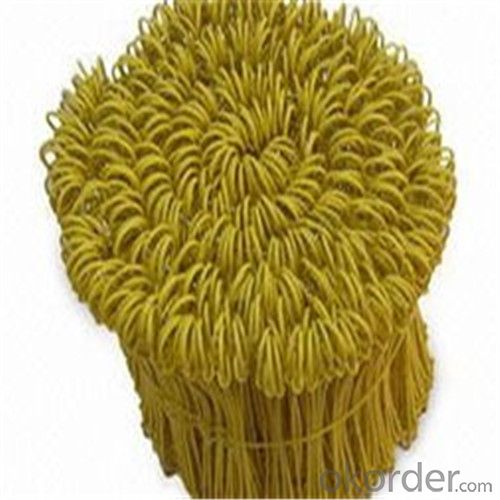

Looped Tie Wire is also known as tie wire or binding wire. It is easy to operate, therefore it's widely uses in binding of different materials, especially for daily use. The main materials of loop tie wires are galvanized iron wire, black annealed iron wire, PVC-coated iron wire and copper wire.

Looped Tie Wire is coated with PVC to create a strong, easy-to-use twist wire tie. PVC coating will not crack, chip or scratch off when tying; meantime this coating provides protection against rust and corrosion. It is widely used for tying and support of plants in gardens or other binding uses, such as tying of sacks and other bagging. This kind of wire is also widely used in securing the position of reinforcing bars during concrete placement.

2.Main Features of Looped Tie Wire:

• Durable

• Practical

• Convenient

• Use widely

• Inexpensive

• Soild

3. Looped Tie Wire Images

4.Looped Tie Wire Specification

Wire Gauge | SWG in mm | BWG in mm | In Metric System mm |

8# | 4.06 | 4.19 | 4.00 |

9# | 3.66 | 3.76 | |

10# | 3.25 | 3.40 | 3.50 |

11# | 2.95 | 3.05 | 3.00 |

12# | 2.64 | 2.77 | 2.80 |

13# | 2.34 | 2.41 | 2.50 |

14# | 2.03 | 2.11 | |

15# | 1.83 | 1.83 | 1.80 |

16# | 1.63 | 1.65 | 1.65 |

17# | 1.42 | 1.47 | 1.40 |

18# | 1.22 | 1.25 | 1.20 |

19# | 1.02 | 1.07 | 1.00 |

20# | 0.91 | 0.89 | 0.90 |

21# | 0.81 | 0.813 | 0.80 |

22# | 0.71 | 0.711 | 0.70 |

23# to 34# also available for galvanized iron wire. | |||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

As a professional manufacture with many years of experiences, we have advanced facilities for production, and most of the products, like Loop tie wire. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②Can we get samples?

Yes, we'd like to send you free samples for your test.

③How long can we receive the product after purchase?

In the purchase of Loop tie wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:why is neutral wire.explain plz

- Any electrical circuit must have at least 2 wires for household service. These can be a hot leg and a neutral, or they can be two hot leads. This is typical for a split-phase 240/120 volt service. The neutral wire is the center tap of the transformer winding supplying the split-phase service. The neutral connection point at the transformer is the center tap of the transformer winding. The household system will carry as much of the total load in the 240 volt wires as possible, limited by the actual configuration of the wiring. And the only current carried in the neutral from your circuit breaker panel to the transformer is the unbalanced portion of the total load. The neutral wire in individual circuits from the circuit breaker panel always carries the same current as does the hot leg wire. The neutral is needed for single circuit runs from the circuit breaker panel to the loads. If you have a perfectly balanced load on both hot legs, you would not need a neutral from the circuit breaker panel to the transformer winding. But perfectly balanced conditions are seldom seen in the average home.

- Q:how do i tap a speaker wire? car audio not really my department

- RE: Why Monster XP speaker cord sounds worse than production facility speaker cord? purely put in Monster XP speaker cord to all my Onkyo audio gadget and now its lots softer than the speaker cord that got here with my Onkyo receiver. quantity was once at 25-35 and it grew to become into loud and sparkling. Now after the Monster XP cord, I would desire to crank the receiver to approximately 50-60 to get the comparable sound...

- Q:Looking for legit (good) speaker wire?or does it depend? are all speaker wire good?the speaker wires are for car audio

- 16 gauge wire to 8 gauge wire. Some people like to pay a lot for the wire by getting name brand, they claim it sounds better. but any wire advertised as speaker wire will do. If you do spend a lot of money for high quality shielded speaker wire, chances are you've already spent more money on your equipment, so It will sound better anyway.

- Q:Does anyone know what color the neutral safety wire is on a 1995 suburban? The one in the ignition harness.

- The yellow wire on the ignition switch harness goes to the transmission range switch (aka park/neutral safety switch) on the transmission, and then the purple wire on the transmission range switch goes to the starter solenoid.

- Q:I made a kill switch for my car. All I need to do now is cut the wire that goes into my engine control module and join it with the switch I made. Would it be fine if I just use wire nuts or some sort of tape to join the wires instead of soldering? The instructions say quot;Step 6: Attach the killswitch wires one to each side of the wire you just cut. Step 7: Tape up all new connection.quot;It says to tape the new connections, but should I use exactly?

- When you are cutting wires Especially when it concerns computers you should make a good mechanical connection and a good connection free from moisture and any type of corrosion. When I splice the wires together I use butt connectors with shrink warp and melt the shrink wrap around the wires after crimping the butt connectors together. You can buy heat shrink wrap at radio shack or any electrical supply store and buy heat shrink tubing to put over the wires. Some will say this is overkill, but since electricity passe's over the outside of the wire this is where you get corrosion and cause yourself headaches if the wire is not mechanically connected correctly. Wire nuts are for household connections like in florescent lamps or inside a connector box and normally used on single strand wire like romex 12/3 or 10/3 but not on multi strand wire. it's best to solder the wires together then heat shrink them if you know how to. Remember that .02 Ohms resistance can cause problems with computer operation hope this helps.

- Q:i have a black, red, and yellow wires in my trunk for a stereo system.i hear about this remote wire being blue (i have a sub/amp that needs a remote wire, ground, and battery) but i dont know which is which and where to put what.please help

- well your battery wire should be at least a 8 guage wire same with the ground. the remote wire should be 18-16gauge

- Q:i want to now which is the live wire and which is nuteral thank you

- On AC it's black is hot and white is nuteral and on DC its black is nuteral and red is hot so be careful and don't get killed. P.S. AC stands for alternating current and DC stands for direct current, now go learn what makes them diffrent and also learn who nicoli tessla is and don't stop learning! Oh yea, while the AC unit is turned on the nuteral wire will be hot so don't touch it because the excited electrons are seeking ground so they will travel through the white wire to ground or through you!

- Q:And i am unsure on how to wire the speakers. Do i just splice the wires from the speakers to the corresponding wires on the harness. P.S. It is not actually in a boat, it will be connected to a 12v battery.

- U JUST RUN THE HOT(RED) WIRE TO THE BATTERY. U ALSO MIGHT HAVE TO HOOK UP THE MEMORY WIRE(YELLOW WIRE) AND THE REMOTE ( SOLID BLUE) WIRE TO THE POSITIVE TERMINAL OF THE BATTERY AS WELL BEACAUSE SOME RADIOS WONT TURN ON WITHOUT THESE WIRES COONECTED. THE WHITE AND GREY WIRES ARE THE FRONT AND THE GREEN AND PURPLE ARE THE BACK SPEAKERS. YOU SHOULD GET THE WIRING HARNESS FOR THE WIRING IF ITS GOING IN A CAR LIKE A JEEP THEN ALL U GOTTA DO IS MATCH THE COLORS UP ITS EASY . BUT STRAIGHT TO A BATTERY DO IT THAT WAY JUST MAKE SURE U HAVE A GOOD GROUND.

- Q:I have a ceiling fixture outlet which has 4 wires coming out (red, black, white and uninsulated ground). There is only one light switch that controls it. I wanted to attach a light fixture to connect to that, but the light fixture only has 3 wires (red, white and green - ground). How do I connect this light fixture to the 4 wires?

- The box in the ceiling was wired in anticipation that someone might want to install a ceiling fan instead of just a light fixture. You need to use a circuit tester to determine if the red or black wire is the one that is controlled by the switch. If you don't have one then remove the screws from the switch, pull it out until you can see the wires that are attached. There should be a black wire on the lower terminal ( power coming in ) then either a black or red attached to the upper terminal. Which ever color is attached to the upper terminal would be the corresponding wire to use in the ceiling box for a light.

- Q:i am installing a headunit, i connected all the wires the match, but i have some left over that i am confused about. from the wires that plug into the radio there is the antenna wire, the remote wire, and the ground with a washer to screw it down, and from the other is set of wires is a solid orange wire, which i have no idea where it goes to. so i connected the remote to the orange wire and didn't hook up the antenna to anything, and bolted down the ground wire. I'm wondering why i have 2 ground wires, and what the orange wire is and what do i connect to it?

- The orange wire may be an illumination wire that controls the illumination or brightness of the head unit's lights when the car's headlights are turned on. You have two grounds because one is a chassis ground used to ground the metal frame on your head unit to the car's ground. Your head unit may or may not have an input for the illumination wire, in which case you need to remove it. I would also ground the head unit's frame using the second ground wire. Try looking online for the pinouts for your particular car's factory head unit. This will take the guesswork out of the install.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Loop Tie Wire/ Binding Wire with Good Quality Factory Direct Lower Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords