Inner Climbing Tower Crane with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descriptions of our tower crane:

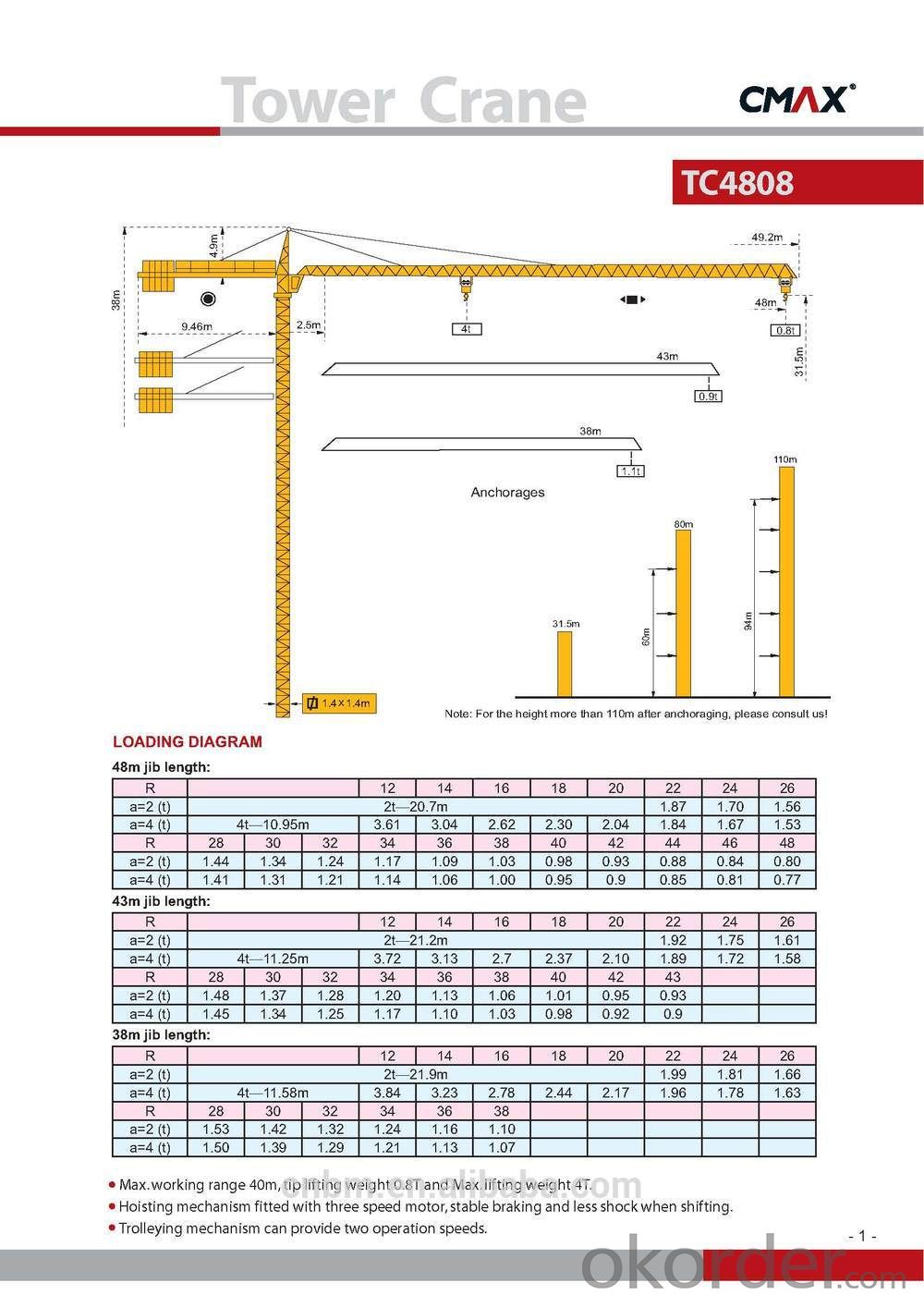

1, TC4808 have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition. With their working radius from 2.25 to 48m, TC4808 tower cranes are famous for their large operating ranges, varied working methods and wide uses.

2,This series of tower cranes has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism.

3, It is original in design, reliable in operation and satisfactory in shape.

4,Equipped with all necessary safety devices, these cranes show a good speed-control capacity,, satisfactory operating stability and high work efficiency.

5,They are widely applied for the construction of high-rise hotels, resident buildings, high-rise industrial buildings, large-span factory buildings and tower like buildings like tall chimneys. Best after sales service will be offered which will get rid of all your worries in the purchase of our products

Advantage of our tower crane:

1, boom relief Angle is big, greatly widened the equipment capacity and scope of work.

2, suitable for the group of tower cross homework.

3, boom stability is good, combination amplitude range.

4, suitable for height have special requirements occasions construction.

5, lifting capacity big, effectively solve the high steel structure construction team crane big lifting capacity requirements.

| Model | QTC50 |

| Tip load capacity (T) | 1 |

| Max.Radius(M) | 56 |

| Independent Height(M) | 41 |

| Max.Lifting Capacity(T) | 6 |

| Max.Height(M) | 161 |

| Wall-attached Frame | 6 |

| Main Material | 135*135*10 Square Steel Tube |

| Standard Mast Section Dimension | 1.84*1.84*2.5 |

| Hoisting Speed(m/min) | 80/40/10 |

| Mini. Stabilizing Falling Speed(m/min) | 5 |

| Slewing Speed (r/min) | 0-0.62 |

| Traveling Speed(m/min) | 40/20 |

| Climbing Speed(m/min) | 0.6 |

| Motor Total Power (KW) | 38.3 |

| Complete Machine Total Weight | Independent Structure Weight (T) 36.8 |

| Counter Weight(T) 14.85 |

- Q:do they get the concrete blocks up that hang at the end? Do they use another type of crane to assemble them?

- Tower cranes assembly starts with the foundation of the crane with lot concrete blocks for fixing, then they fix the first bottom part of the crane then they fix the boom with the counter weights, when they want to extend the height, they fix a jack up machine which lift up the boom and then insert a vertical piece and so on till they reach the required height. During the first installation they use a small mobile crane and then after the crane it self lift and fix the pieces

- Q:Basically what it says on top. Also provide maybe a video to prove it.

- ok,im not sure about it but...maybe if you spred the wings far enough wait for good wind and throw it at a correct angle/thrust then it is possible otherwise it will crash

- Q:Like the tall cranes on construction sites. I mean, suddenly they're just magically there!

- so trueee!

- Q:what does dog everything mean in crane lift lingo?

- it means to stop the crane from doing anything, just sit still untill otherwise told to carry on

- Q:I'd take Denny Crane he's ruthless

- Denny Crane. If nothing else he has a heck of a lot of confidence in himself.

- Q:I have a Holden 253 and I'm looking at a hydraulic street/strip cam, and I'm wondering which brand is better out of Crow and Crane?Cheers.

- both are good id go with crane but look at the cam duration and decide whats best for your engine and if one of them comes as a kit like with your hydraulic lifters and push rods get that.

- Q:What is the load moment of a crane?

- The load moment for a crane is a number measuring the weight of the load lifted times the distance between the mass and the centre of the crane's superstructure. For example, a 20 ton weight lifted at 5m away from the crane (in reality, right next to it!) gives us a load moment of 100 ton*m, the same as a 10 ton weight lifted 10m from the crane. Cranes can handle higher load moments closer to the crane, so really heavy lifts are always done from very close to the load.

- Q:Were the anti-gravity machines used to build the pyramids levers, winches and cranes?

- Levers winches and cranes all use a counter balance. Its weight that helps move weight in different ways. There is no such thing as an anti-gravity machine.

- Q:from the legend of sleepy hollow, his background, characater, personality, life etc.

- These websites should help you find the answers to your questions

- Q:How do cranes get from one construction site to another without hitting streetlights, wires, car, buildings?

- They dodge by the stuff as they fly along. Duhhh

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Inner Climbing Tower Crane with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords