High Density Polyethylene Geocell with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of High Density Polyethylene Geocell:

Our geocell canbe made of PP/HDPE/plastic,

length:6.22m ;

thickness: 1-2mm

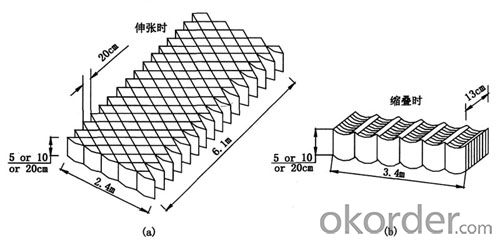

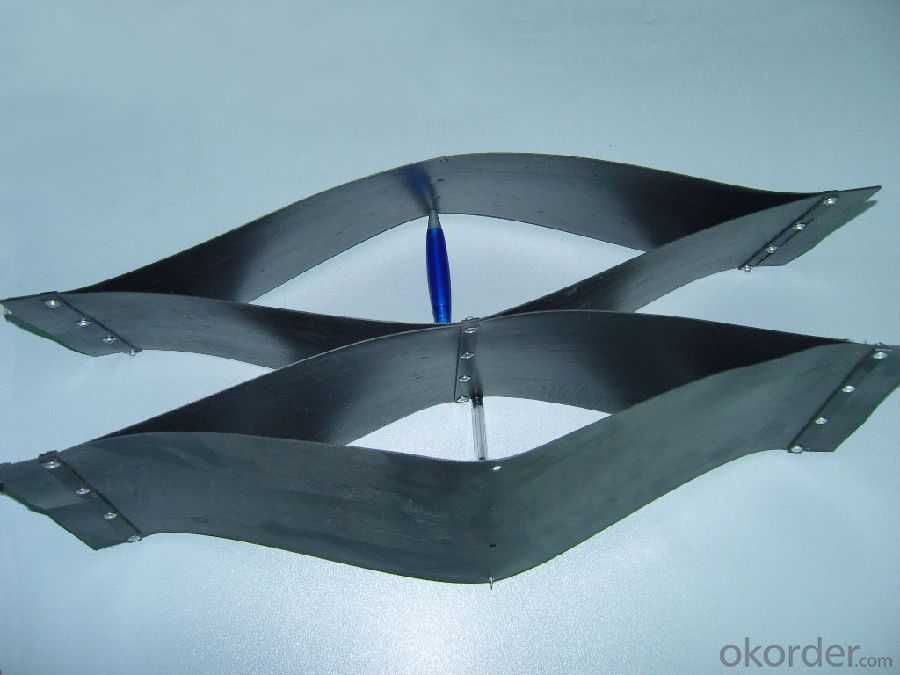

Geocell is a net-shaped cell structure made by welding high intensity thermoplastic sheet. It is flexible folded during service, and forming into struct with powerful lateral confinement and rigidity.

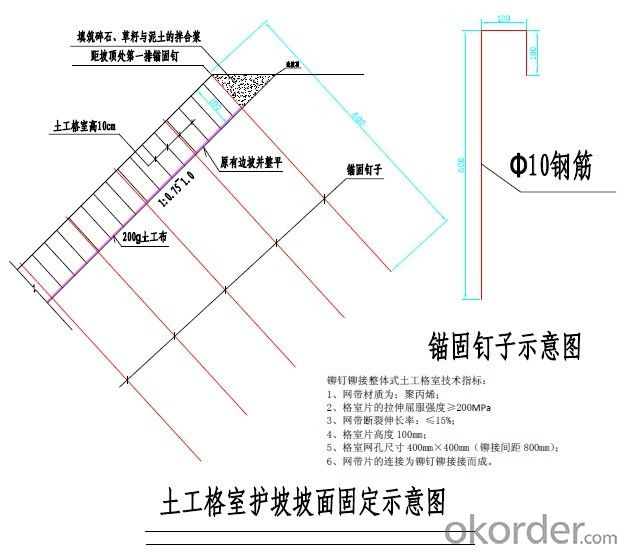

It can be used as cushion coat to strengthen loading capacity of weak ground or slope protection

structure, as well as stop structure, and so on.

Main Features of High Density Polyethylene Geocell:

1. Fix railway ground .

2. fix weak ground of roads .

3. block loading capacity.

4. treat river way of shallow water.

5. act as support in pipeline and sewer.

6. act as comprehensive block stopping land sliding and bearing loading capacity.

7. act as independent wall, dock and break-water.

8. treat desert, beach, riverbed and bank.

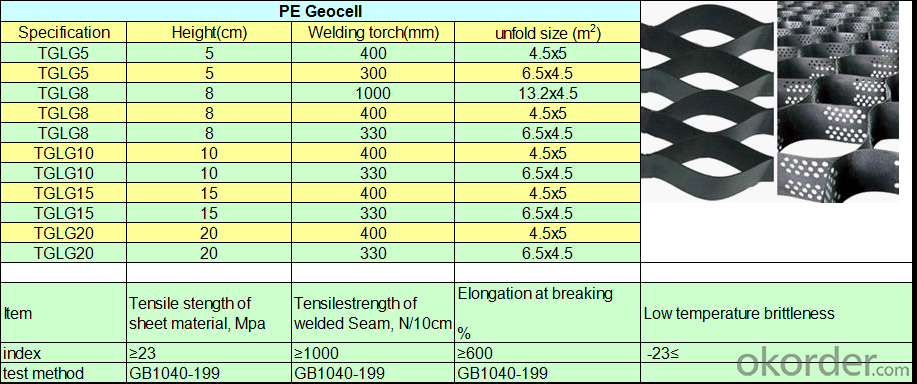

Specifications of High Density Polyethylene Geocell:

1.TGLG5 TGLG8 TGLG10 TGLG15 TGLG20(CM)

2.Stretch size :4mx5m or 6m x7m or at your request.

3. General roadbed reinforcement with 330 mm, 400 mm.

Slope protection with 500 mm, 660 mm

4.Executive standard:GB/T19274-2003

Technical specification of geocell

Applications of High Density Polyethylene Geocell:

1. processing half fill Semi roadbed

build up the embankment on the ground on the slopes of the natural slope ACTS in 1:5, supporting subsoil should dig the steps, The step width shall be less than 1 m, when building or rebuilding roads widened by installments, Convergence between the new and old roadbed fill slope ,should dig the step, high grade highway width is 2 m, laid large geocell in each of the steps horizontally, using the large geocell of their own facade confining reinforcement effect, better solve the problem of uneven settlement

2. subgrade in wind drift sand region

Sand subgrade should be given priority to with low embankment, region filling height not less than 0.3 m. generally due to its low subgrade, sand subgrade construction in professional requirements and heavy load, adopting large chamber loose packing confining effect, can be in limited the height of the roadbed with high stiffness and strength, to inherit the load stress of large vehicles.

3. Reinforced back subgrade soil

Using large geocell can better achieve the goal of abutment back reinforced , can generate enough friction between the geocell and packing . and effectively reduce roadbed uneven subsidence, finally can effectively relieve the abutment jump car "disease early impact damage of bridge deck.

4. subgrade in permafrost region

In permafrost regions fill roadbed construction, should reach a minimum filling height in order to prevent or cause a frozen layer ceiling Frothing decreased, resulting in an excess of embankment settlement occurs. Geocell unique overall unconfined facades reinforced effect and effectively implemented, can ensure a minimum filling height in some special area to the maximum extent, and to fill a high-quality strength and stiffness.

5. The collapsibility loess roadbed treatment

When the highway and the highway collapse loess and loess lot better compression by wet, or foundation bearing capacity is lower than the high embankment to allow third-party vehicle load and weight of pressure embankment, subgrade bearing capacity requirements should also for processing, then the superiority of Geocell on manifest is no doubt.

IMages of Plastic Geocell/HDPE geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:What is the mechanism of homogeneous membrane pressure transmitter?

- it is the most commonly used sensor in industrial applications, and it is widely used in water conservancy and hydroelectric power, railway transportation, intelligent buildings, production automation, aerospace, military project, petrochemical, oil well, electric power, shipbuilding, machine tools, plumbing and other industries. the mechanism is: Medium pressure is directly acted on the sensitive diaphragm and distribution on the resistance of the sensing membrane composition of Wheatstone bridge, using piezoresistive effect of the amount of pressure conversion to electrical signals, through the electronic circuit of sensitive element of millivolt signal amplification for industrial standard signal.

- Q:What are the differences of geotextiles and geogrids?

- Geogrids can be used to reinforce the soil mass and improve the integrity just like the reinforcing bar in concrete. Geotextiles can be used in seepage control engineering. I have place the multilayer non-woven geotextiles and geomembranes on the rubbish dam and anchoring platform of a refuse landfill. There are some tips about geotextiles. Geotextiles can be divided into two categories, namely the impervious geotextile and permeable geotextile. Geomembranes and impervious geotextiles can be used to prevent emission of the ground water caused by capillarity. Geotextiles are porous to liquid but soil can't go through them. For example, they are used on the surface of supporting sewers of high slopes and in the roadbeds above water level (water in roadbeds can freely diffuse through the permeable geotextile just as in the roadbed blind ditches).

- Q:What are the applications of geomembrane in roadbed?

- Geomembrane in the roadbed is not only strengthening the subgrade, but also plays a role in the anti-seepage and anticorrosion. The geomembrane has good heat resistance and cold resistance. good chemical stability, high rigidity and toughness, good mechanical strength, environmental stress cracking resistance and tearing strength. With density is rising, the mechanical properties and barrier properties will be a corresponding increase, heat resistant, and the tensile strength is higher; It can resisit the corrosion of acid, alkali and organic solvents and others.

- Q:Why composite geo-membrane can not be used in underground garage?

- Composite geo-membrane was invented in China, applied in the The South-to-north Water Diversion Project with good anti-seepage effect. While there are no composite geo-membrane in foreign countries. It has also been widely used in subway?tunnel and other underground constructions. Of course, it can be used in underground garage , but you must choose the appropriate specifications. It is recommended to use 300g/1.0mm/300g composite geo-membrane. The following are the details. Composite geo membrane is geotechnical impermeable material made of plastic film as anti-seepage material and non-woven fabrics. Its waterproof performance mainly depends on the performance of plastic film. Impermeable plastic film at home and abroad are mainly polyvinyl chloride (PVC) and polyethylene (PE), which are Polymer chemistry flexible material with smaller proportion, good extensibility and high?adaptability?to the?deformation. Corrosion resistance, low temperature resistance, good anti-frost?property. The main mechanism is to block earth dam leakage passage by imperviousness of plastic film and bear hydraulic?pressure and adapt to deformation of dam with greater tensile strength and elongation. Non-woven geotextile is also a kind of macromolecule staple fibre chemical material shaped through acupuncturing or hot sticking, having high tensile strength and extensibility. Combined with plastic film, it can not only increases the tensile strength and anti-puncture ability of plastic film, but also increase the friction coefficient of contact surface and make the composite geo-membrane and packaging layer stable as the non-woven fabrics surface becomes rough. At the same time, they have good corrosion resistance to bacteria and chemical action, not afraid of acid, alkali, salt erosion, high seepage coefficient.

- Q:How do geomembranes perform in high seismic activity gas containment applications?

- Geomembranes are a highly effective solution for gas containment applications in areas with high seismic activity. They are designed to withstand intense ground shaking and provide excellent resistance to earthquake-induced ground movements. The flexibility and tensile strength of geomembranes allow them to withstand the dynamic forces generated during seismic events, ensuring the integrity of the gas containment system. Additionally, geomembranes have low permeability, preventing the leakage of gas, even in challenging geological conditions. Therefore, geomembranes perform exceptionally well in high seismic activity gas containment applications, providing a reliable and durable solution.

- Q:What are the differences of seepage-proof geomembrane and polypropylene fiber impervious geotextile?

- The seepage-proof geomembrane is made of high density polyethylene by flat extrusion or blow molding. The white seepage-proof geomembrane is heated and covered with polypropylene fiber geotextile top and bottom which finally becomes polypropylene fiber impervious geotextile. It has a good extensibility and environmental resistance as well as better anti-seepage effect. The seepage-proof geomembrane is usually black or white HDPE.

- Q:Characteristics of geomembrane

- Geomembrane as a new material, has excellent seepage-proof property, antiseptic property, good chemical stability and features and functions which can be processed according to the actual project needs. Geomembrane has been widely used in dyke, dam , reservoir seepage-proofing in water conservancy engineering, at the same time, geomembrane is also used as seepage-proof, corrosion-proof, leak-proof and moisture-proof materials in areas like channels, impounding reservoir, cesspit, swimming pool, housing construction, underground structures, wasteyard and environmental engineering, etc.

- Q:What are the considerations for geomembrane installations in areas with high temperature differentials?

- When installing geomembranes in areas with high temperature differentials, several considerations need to be taken into account. Firstly, the choice of geomembrane material is crucial. It should have a high resistance to thermal expansion and contraction to withstand the temperature variations. Additionally, the material should be able to maintain its flexibility and integrity even in extreme temperature conditions. Proper anchoring and securing methods are also important. The geomembrane should be securely anchored to prevent any potential movement or displacement caused by temperature fluctuations. This may include using anchor trenches, ballasting, or other appropriate methods to ensure its stability. Furthermore, thermal stress relief measures should be implemented. These can include incorporating stress relief features such as expansion joints or incorporating a geotextile cushion layer to minimize the transmission of thermal stresses to the geomembrane. Finally, regular inspections and maintenance are crucial to identify any potential issues or damages caused by the high temperature differentials. Prompt repairs or replacements should be carried out to prevent further damage and maintain the effectiveness of the geomembrane installation.

- Q:Can geomembranes be used for landfill liners?

- Yes, geomembranes can be used as landfill liners. They are highly effective in preventing the leakage of pollutants and contaminants from landfill sites into the surrounding environment. Geomembranes act as impermeable barriers, preventing the migration of liquids and gases, thus protecting the soil and groundwater from potential contamination.

- Q:What is the role of geomembranes in landfill construction?

- Geomembranes play a critical role in landfill construction as they act as a barrier to prevent the leakage of hazardous substances and contaminants into the surrounding soil and groundwater. They are used as liners or covers on the base and slopes of landfills, effectively containing and isolating waste materials. Additionally, geomembranes help to control gas emissions, minimize odors, and provide stability to the landfill structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Polyethylene Geocell with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords