HDPE Pond Liners HDPE Geomembrane Smooth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geomembrane

1.Gas Defence fish pool liner vinyl pool liners

2.1m-8m width

3.0.2mm-3.0mm thickness

Geomembrane specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

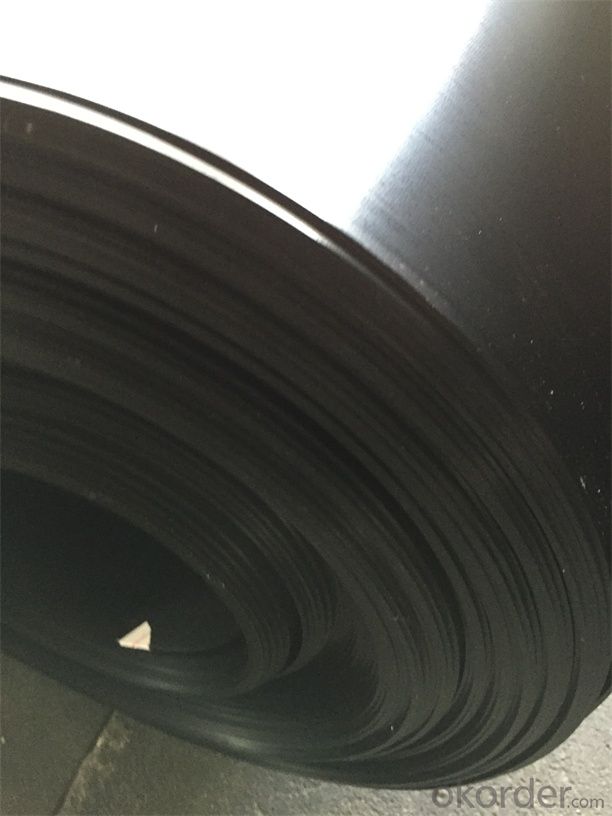

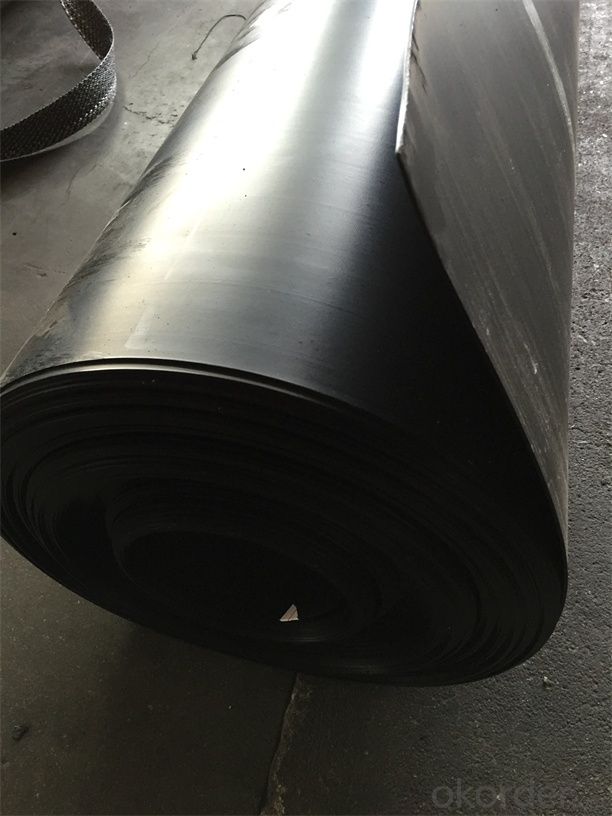

Gemembrane Show:

- Q:How do geomembranes contribute to the prevention of slope erosion?

- Geomembranes contribute to the prevention of slope erosion by acting as a barrier between the soil and the surrounding environment. They provide a waterproof and impermeable layer that helps to control water flow and prevent the infiltration of moisture into the soil, which is a common cause of slope erosion. By effectively reducing water seepage and preventing soil movement, geomembranes help to stabilize slopes and protect them from erosion.

- Q:Home color film and the film pvc wallpaper What is the difference?

- Ingredients: Wall membrane: Using natural materials, free of PVC, free of formaldehyde, benzene, toluene and other toxic substances. Wallpaper: Use paper | PVC construction method: Wall membrane: Technology low, easy to glue, white-wall film and adhesive properties, easy mosaic, wallpaper: high requirements, high material loss. Decorative: Wall membrane: Rich in texture, in three-dimensional, the preparation of patterns and colors with any class, you can paint, can change color when recoated. Wallpaper: Surface gloss, colorful patterns. You can not paint. . Can not change the color; repairability: Wall membrane: For multiple brushing renovation, it can be partially repaired. Wallpaper; can not repair, can only be partial or total replacement. Stability: Wall membrane: Do not fade, mildew, non-toxic odor-free, anti-moth. Wallpaper: fade, mildew, shedding, odor, anti moisture not good. Life: Wall membrane: 30 years (can be changed within 8 colors) Wallpaper: 5 years Economy: Wall membrane: Simple construction, low loss, can be repeatedly brushing, long service life. Wallpaper: Parquet, while trimming losses high, short life.

- Q:Which one is better, oil heater or electrothermal?film?

- Both oil heater and electrothermal?film are pure resistance circuit, using resistance to heat things, thus their efficiency is almost the same. Oil radiator is heated slowly and it will dissipate the heat slowly for a while after the electricity is cut off. The electrothermal?film is heated quickly and it gets clod as soon as the electricity is cut off. But the heat productivity is almost the same at the same power. Heating capacity and power consumption of the two products are the same. The electrothermal?film is smaller. The electrothermal film is recommended.

- Q:How much degree can high-density hdpe geomembrane withstand?

- geomembrane produced in standard will absorb heat under sun, up to 50- 60 degrees. The average temperature tolerance is at about 70 degrees. Heat tolerant geomembrane made by new technology can operate at 100 degrees.

- Q:Are geomembranes resistant to punctures from tree roots?

- Yes, geomembranes are generally resistant to punctures from tree roots.

- Q:What is national standard of geomembrane?

- Polyethylene geomembrane new national standard GB / T17643-2011. The new standard increases single rough geomembrane and double rough geomembrane and delete EVA geomembrane.

- Q:Can geomembranes be used for landfill capping?

- Yes, geomembranes can be used for landfill capping. They are often used as a barrier to prevent the escape of contaminants from the landfill into the surrounding environment. Geomembranes provide an impermeable layer that helps to contain the waste and protect the underlying soil and groundwater.

- Q:How do geomembranes help with environmental protection?

- Geomembranes help with environmental protection by acting as a barrier to prevent contamination and pollution. They are used to line landfills, ponds, and other containment areas to prevent leaks and seepage of hazardous substances into the surrounding soil and groundwater. Additionally, geomembranes are employed in erosion control measures to prevent soil erosion and sedimentation, thus protecting natural habitats and water bodies. Overall, these impermeable membranes play a crucial role in safeguarding the environment from harmful impacts and ensuring the sustainability of our ecosystems.

- Q:Membrane wall texture paint it green

- Similar film texture wall wallpaper liquid, low-end wall coverings. Diatom mud are high-end, environmentally sound wall decoration materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Pond Liners HDPE Geomembrane Smooth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords