All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

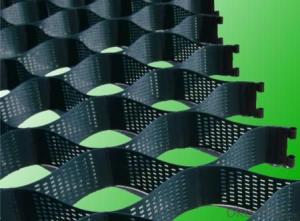

How are geomembranes used to prevent the corrosion of pipes and tanks in industrial settings?

Geomembranes are used in industrial settings to prevent the corrosion of pipes and tanks by acting as a protective barrier. These impermeable membranes are placed between the soil or other corrosive materials and the pipes or tanks, effectively isolating them from potential corrosive agents. By preventing direct contact and the infiltration of moisture, chemicals, or other harmful substances, geomembranes help to increase the lifespan and durability of pipes and tanks, reducing the risk of corrosion and associated maintenance costs.

What are the design considerations for geomembrane floating covers?

Some design considerations for geomembrane floating covers include selecting a suitable geomembrane material that is resistant to UV degradation and chemical exposures, ensuring the cover is securely anchored to prevent wind uplift and water infiltration, incorporating a gas venting system to release accumulated gases from under the cover, and considering the impact of temperature changes on the cover's flexibility and integrity. Additionally, factors such as the shape and size of the cover, site-specific conditions, and regulatory requirements should also be taken into account during the design process.

Are geomembranes resistant to bacterial growth?

Yes, geomembranes are generally resistant to bacterial growth. These synthetic liners are designed to be impermeable and provide a barrier against microorganisms, including bacteria. The materials used in geomembranes, such as high-density polyethylene (HDPE), are inert and do not provide a suitable environment for bacterial growth. Additionally, geomembranes are often installed with proper seaming techniques and are frequently used in combination with geotextiles and other protective layers to further prevent bacterial colonization.

What are the different methods of geomembrane repair?

The different methods of geomembrane repair include patching, welding, and adhesive bonding. Patching involves applying a patch or sealant material over the damaged area to prevent further leakage. Welding is a common method where the damaged geomembrane is heated and fused together using a specialized welding tool. Adhesive bonding involves using a strong adhesive to bond the damaged area back together. These methods vary in complexity and effectiveness depending on the type and extent of the damage.

Wholesale Geomembranes from supplier in Bulgaria

With our partnership with CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with a seamless procurement experience for Geomembranes in Bulgaria. Our team goes beyond just sales and quotations; we offer technical support tailored specifically to the Bulgarian market.

We understand that every project is unique, which is why we offer a comprehensive range of Geomembranes to suit your specific requirements. Our years of experience in the Bulgarian market have given us valuable insights and knowledge that we can apply to your projects, ensuring their success.

By choosing us as your Geomembranes supplier in Bulgaria, you can take advantage of our one-stop procurement services and industry expertise. We are dedicated to delivering exceptional products and support that meet your exact needs. Contact us today to learn more about how we can assist you with your Geomembranes procurement needs in Bulgaria.

We understand that every project is unique, which is why we offer a comprehensive range of Geomembranes to suit your specific requirements. Our years of experience in the Bulgarian market have given us valuable insights and knowledge that we can apply to your projects, ensuring their success.

By choosing us as your Geomembranes supplier in Bulgaria, you can take advantage of our one-stop procurement services and industry expertise. We are dedicated to delivering exceptional products and support that meet your exact needs. Contact us today to learn more about how we can assist you with your Geomembranes procurement needs in Bulgaria.