All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

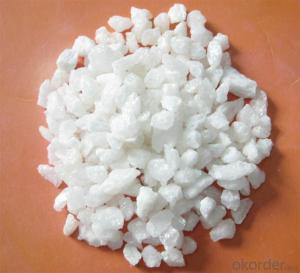

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are refractory anchor systems designed and used in furnace linings?

Refractory anchor systems are designed and used in furnace linings to provide support and stability to refractory materials. These systems consist of metal anchors that are embedded in the refractory lining and attached to the furnace shell or steel structure. The design and selection of refractory anchors depend on factors such as furnace temperature, lining thickness, and material type. They are strategically placed to prevent the movement and displacement of refractory materials during thermal expansion and contraction, ensuring the integrity and longevity of the furnace lining.

What are the advantages of using magnesium oxide as a raw material in refractory production?

One advantage of using magnesium oxide as a raw material in refractory production is its high melting point and thermal stability. This means that refractories made from magnesium oxide can withstand high temperatures without losing their structural integrity, making them ideal for applications in industries such as steelmaking and glass manufacturing. Additionally, magnesium oxide has excellent resistance to corrosion and chemical attack, ensuring the longevity and durability of the refractory materials. Furthermore, magnesium oxide-based refractories have good mechanical strength and abrasion resistance, enabling them to withstand harsh operating conditions and maintain their performance over time. Overall, the use of magnesium oxide as a raw material in refractory production offers superior heat resistance, chemical stability, and mechanical strength, making it a preferred choice in various industrial settings.

What are the raw materials used in the production of ramming mass refractories?

The raw materials used in the production of ramming mass refractories typically include high-quality silica, alumina, and other additives such as binders and plasticizers.

What are the advantages of using chamotte in refractory applications?

Chamotte, also known as fireclay, offers several advantages in refractory applications. Firstly, it has excellent thermal insulation properties, allowing it to withstand high temperatures without significant heat transfer. Additionally, chamotte has good resistance to chemical corrosion, making it suitable for use in aggressive environments. It also has a low thermal expansion coefficient, which reduces the risk of cracking and ensures dimensional stability. Furthermore, chamotte is readily available and cost-effective, making it a popular choice in various refractory applications.

Wholesale Raw Materials For Refractory from supplier in Bulgaria

With our expertise and resources, we can ensure that you receive high-quality raw materials for your refractory products in a timely manner. Our team is well-versed in the Bulgarian market and can provide you with accurate sales and quotations that cater to your specific requirements.

Furthermore, our technical support services are designed to assist you throughout the entire procurement process. Whether you need assistance in selecting the right raw materials or require guidance on their application, our experienced team is here to help.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a wide range of raw materials for refractory products. This enables us to offer you a comprehensive selection of products to choose from, ensuring that you find the perfect solution for your projects.

Our market development experience in Bulgaria is another advantage we bring to the table. We have a deep understanding of the local market dynamics, regulations, and customer preferences. This allows us to provide you with valuable insights and recommendations that can contribute to the success of your projects.

Partnering with us means gaining a trusted and reliable supplier for all your raw materials for refractory needs in Bulgaria. We are committed to delivering exceptional products and services to our customers, and we look forward to the opportunity to serve you. Contact us today to discuss your requirements and let us assist you in achieving your project goals.

Furthermore, our technical support services are designed to assist you throughout the entire procurement process. Whether you need assistance in selecting the right raw materials or require guidance on their application, our experienced team is here to help.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a wide range of raw materials for refractory products. This enables us to offer you a comprehensive selection of products to choose from, ensuring that you find the perfect solution for your projects.

Our market development experience in Bulgaria is another advantage we bring to the table. We have a deep understanding of the local market dynamics, regulations, and customer preferences. This allows us to provide you with valuable insights and recommendations that can contribute to the success of your projects.

Partnering with us means gaining a trusted and reliable supplier for all your raw materials for refractory needs in Bulgaria. We are committed to delivering exceptional products and services to our customers, and we look forward to the opportunity to serve you. Contact us today to discuss your requirements and let us assist you in achieving your project goals.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Nepal

- Refractory Bricks in Dominican

- Raw Materials For Refractory in Tuvalu

- Raw Materials For Refractory in Mauritania

- Raw Materials For Refractory in Bahrain

- Ceramic Fiber Products in Niger

- Ceramic Fiber Products in Maldives

- Raw Materials For Refractory in France

- Raw Materials For Refractory in Indonesia