All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

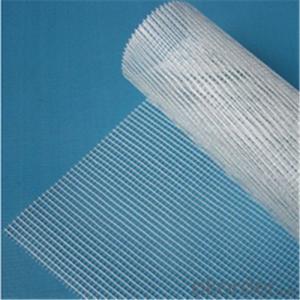

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

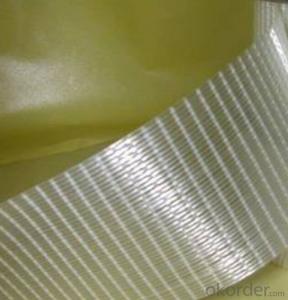

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

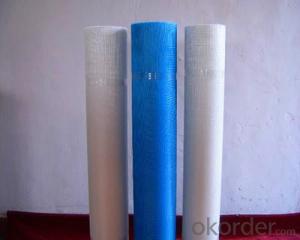

Fiberglass Mesh ClothView More

Composite PipesView More

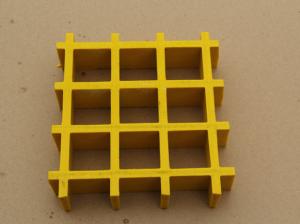

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

How does the weather resistance of fiberglass compare to other materials?

Fiberglass is highly weather-resistant compared to many other materials. It has excellent resistance to moisture, UV radiation, and extreme temperature fluctuations, making it a durable choice for outdoor applications. Moreover, fiberglass is non-corrosive and does not rust, rot, or degrade easily, making it suitable for various weather conditions.

How do you reinforce architectural components with fiberglass materials?

To reinforce architectural components with fiberglass materials, the first step is to thoroughly clean and prepare the surface of the component. Next, a layer of fiberglass cloth or mat is applied to the component and saturated with a resin, typically epoxy or polyester. This mixture is then pressed onto the surface, ensuring complete adhesion. Multiple layers may be added, depending on the desired strength and durability. The fiberglass is left to cure, which typically takes several hours or even days. Once cured, the reinforced component can be sanded, painted, or finished as desired.

How is fiberglass used in the production of railcar components?

Fiberglass is commonly used in the production of railcar components as it offers several advantages. It is lightweight yet strong, making it an ideal material for constructing various parts of railcars such as panels, covers, and interior components. Fiberglass is also resistant to corrosion, which is crucial for railcars that are exposed to harsh weather conditions and different environments. Additionally, fiberglass can be molded into different shapes and sizes, allowing for customization and efficient manufacturing of railcar components.

Can fiberglass supply be used for making wind turbine blades?

Yes, fiberglass supply can be used for making wind turbine blades. Fiberglass is a commonly used material in the construction of wind turbine blades due to its high strength, durability, and light weight. It allows for the efficient capture of wind energy while providing structural integrity to the blades.

Wholesale Fiberglass Supply from supplier in Bulgaria

Whether you are in need of Fiberglass Supply products for construction, industrial, or other applications, we have you covered. Our product range includes fiberglass panels, roofing sheets, insulation materials, pipes, tanks, and more. We source our products from reputable manufacturers, ensuring high-quality and reliable performance.

In addition to our wide range of products, we also offer competitive pricing and flexible delivery options to meet your specific requirements. Our dedicated sales team is available to provide personalized quotations and assist you in finding the best solutions for your projects.

Furthermore, we understand the importance of technical support in the successful implementation of Fiberglass Supply products. Our team of experts is well-versed in the technical aspects of fiberglass materials and can provide guidance and assistance throughout your project's lifecycle.

As a subsidiary of CNBM, we have access to a global network of suppliers and resources, which enables us to offer comprehensive procurement services. We strive to streamline the procurement process, saving you time and effort by handling all aspects of product sourcing, logistics, and delivery.

Whether you are a contractor, engineer, architect, or distributor, we are committed to meeting your Fiberglass Supply needs in Bulgaria. Contact us today to discuss your requirements and discover how we can assist you in achieving your project goals.

In addition to our wide range of products, we also offer competitive pricing and flexible delivery options to meet your specific requirements. Our dedicated sales team is available to provide personalized quotations and assist you in finding the best solutions for your projects.

Furthermore, we understand the importance of technical support in the successful implementation of Fiberglass Supply products. Our team of experts is well-versed in the technical aspects of fiberglass materials and can provide guidance and assistance throughout your project's lifecycle.

As a subsidiary of CNBM, we have access to a global network of suppliers and resources, which enables us to offer comprehensive procurement services. We strive to streamline the procurement process, saving you time and effort by handling all aspects of product sourcing, logistics, and delivery.

Whether you are a contractor, engineer, architect, or distributor, we are committed to meeting your Fiberglass Supply needs in Bulgaria. Contact us today to discuss your requirements and discover how we can assist you in achieving your project goals.