Good Price and High Quality MGO-C Brick for Steel Ladle

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company Profile

CNBM INTERNATIONAL CORPORATION

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019).

Refractory Technology

Our plant was one of the research institutes on refractory materials in CNBM. It was set up in 2001.

Taking the advantages of combining research,process,marketing and technical service,CNBM supply not only first-class refractory materials but also supply distinctive technical services.

CNBM has been dedicated to expand grow space via resource integration and product diversification.5 subsidiaries has been set up by June,2010.

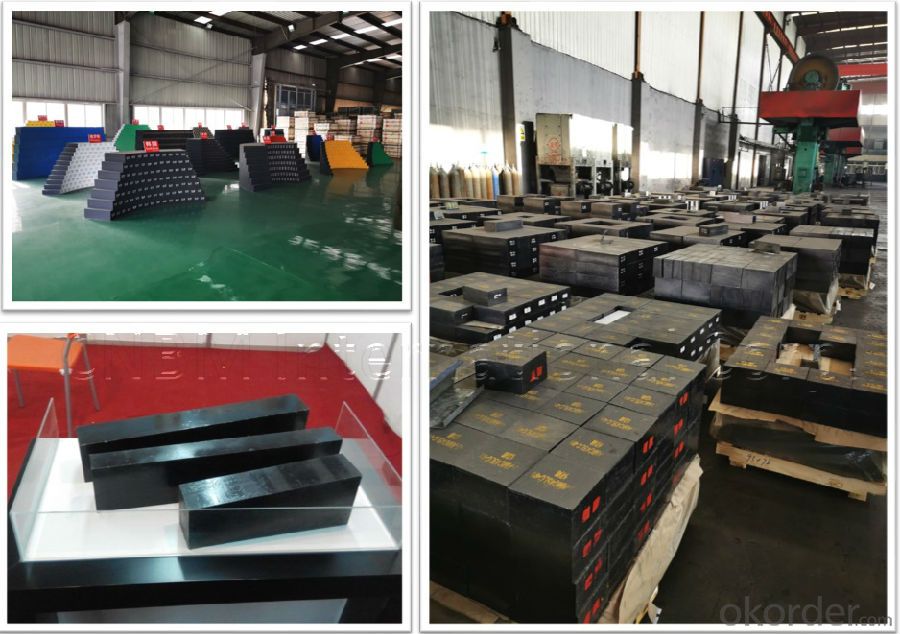

Refractory Plants

·Our annual output is 5000,000 tons per year.

·Our plant are ISO 9001:2008 certificated

·The products cover the refractory area of steel-making, cement, non-ferrous, glass, ceramic and others.

Feature of Magnesia Carbon Brick

Excellent resistance in slag abrasion

Higher temperate resistant with good refractoriness

Lower creep in high temp.

Good thermal shock resistance performance

Lower apparent prosity

not easily wet with slag

Specifications of Magnesia Carbon Brick

MgO and carbon content

Widely used throughout metallurgical industry

Physical And Chemical Indicators For Magnesia Carbon Brick

| Item | MZ-97A | MZ-97B | MZ-95A | MZ95B | MZ-93 | MZ-91 | MZ-89 | DMZ98 | DMZ97 | DMZ96 |

| Density(g/cm3)≥ | 2.96 | 2.96 | 2.94 | 2.94 | 2.94 | 850 | 900 | 3.1 | 3.1 | 3 |

| Cold Crushing Strength (Mpa)≥ | 60 | 60 | 60 | 60 | 60 | 60 | 50 | 90 | 90 | 90 |

| Reheating Linear Change (%) | 1650ºC x 2h 0~ -0.2 | 1650ºC x 2h 0~ -0.3 | 1650ºC x 2h 0~ -0.4 | 1650ºC x 2h 0~ -0.6 | - | - | - | |||

| Refractoriness Under Load(ºC)≥ | 1700 | 1700 | 1650 | 1650 | 1620 | 1560 | 1550 | 1700 | 1700 | 1700 |

| Apparent Porosity (%)≤ | 16 | 18 | 16 | 18 | 18 | 18 | 20 | 14 | 14 | 15 |

| MgO(%) | 97.0 | 96.5 | 95.0 | 94.5 | 93.0 | 91.0 | 89.0 | 97.7 | 97.1 | 96.3 |

| SiO2(%) | 1.0 | 2.0 | 2.0 | 2.0 | 3.5 | - | - | 0.58 | 0.97 | 1.20 |

| CaO(%) | - | - | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 0.63 | 0.97 | 1.30 |

| Application | Kiln Linning in Iron and Steel, Copper, Lead, Tin and Zinc Industries | The Tap Hole of Steel Furnace; Tap Hole and Slag Line in Non-Ferrous Industry | ||||||||

Our Services

Free samples are available by freight collect;

Strict QC & Fast delivery

High quality goods, Perfect Pre-sales and after-sales service.

CNBM will update you any production process after placing order.

We have special after-sales team to solve your problem during using our products.

Any question will be get our feedback in the first time.

Packaging & Shipping

Packaging : Packed by sea-worthy wooden pallet + shrink wrapped + carton

For example, Standard size of Fireclay brick : 230X114X65mm

Shipping : 384PCS/plt X 18plts in one 20 feet container;

Proprietary Technology & Patented Products

Refractory technology

All process are conform to ISO9001 quality control systems

(1)The test of raw materials

★For all raw materials, the purchase department should give the test report to the quality supervision department.

(2)The control of production

★Each batch products should be tested

★The quality supervision department should record all test result.

(3)Test Before Production

★Before packing, the quality supervision department should test the chemical content and physical

★Only quality products can be delivery.

★The delivery department should check the package, quantity, name, code, production date, etc.

(4)Quality Traceability Analysis

★Track the products after using and get the feedback of performance.

If customer required, we will give the customer technical solutions and also improve the products.

Damage Mechanism Analysis and Improvement

★ For the maintenance project, CNBM will check the damage condition of the refractory materials in the furnace carefully.

★And then CNBM will give the damage mechanism analysis report to the customer.And CNBM also will provide products improvement solutions to extend the products' service life.

Technical Solution& Construction

★Optimization solutions of the original design to the customer.

★Consultation Service of Refractories Technology

★Technical Staff Training in Refractories Technology

★Specialized Design and Refractories Selection

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q:Why should the clay bricks be watered first when they are building masonry walls?

- And because a portion of the water in the mortar brick absorb, can lead to early dehydration, but are not very good on the hydration of the brick and mortar bond strength weakened, greatly reduce mortar and masonry compressive strength, shear strength, affecting the integrity and seismic performance of masonry.

- Q:What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- Generally speaking, compared with the exterior burning brick, the internal combustion brick not only saves the clay and the waste material, but also has smaller volume density, lower thermal conductivity, and can increase the intensity by about 20%. Burnover light color, sound, low intensity; burned brick deep color, crisp sound, high strength, irregular size. These two kinds of bricks are unqualified products.

- Q:What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q:does Kyrgyzstan have the refractory brick to build tunnel kiln, whose specifications are 390,235,11, 240,120,60.

- Domestic standard brick has no brick in this specification. only can be customised. Otherwise only have 230 * 65 * 114.

- Q:th choose of different refractory bricks in the rotary?kiln

- According to the characteristics of each belt, magnesium chromium brick. Take the most kiln foe example, the configuration of kiln refractory is not the same, the burning of the product is not the same. there are many kinds of rotary kiln. magnesia bricks are generally used in high temperature zone, anti-stripping alumina brick,silmo brick are used in temperate zone, clay brick is mainly used in low temperature zone. generally inlet and the outlet use corundum mullite, wear-resistant castable, spinel brick,etc. select brick of proper performance, but also take into account the economy

- Q:What is the heating temperature in the test method of thermal shock resistance of refractory bricks

- 1, quenching (air cooling or water cooling), after the completion of the specified number of times. 2, maintain 20min, introduce the following types briefly. 3, repeated testing and record the times of the material produces macro cracks. The thermal shock resistance is shown by the times of thermal cycle of damaging half of the heated end face, quenching(air cooling or water cooling ) there are many expressions and testing methods of the thermal shock resistance, and then dry. Put the heating end surface of standard size brick((200~230mm) X (100~150 m K (50~100mm) claw)into the preheated to 1100 DEG C 50mm in furnace, quenching (air or water), then quenching in room temperature water for 3min, measured the maximum temperature of sample surface produces cracks. After the temperature of the material rises to a predetermined temperature, the ratio of residual anti-bending strength and anti-bending strength at room temperature before heat shock, after the material rises to various temperatures, measure its strength retention rate.

- Q:what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q:How about clay bricks?

- Fired ordinary brick is one of the indispensable building materials in production and life, but its quality is not good or bad in the absence of professional equipment. Now to introduce a little trick:According to the main raw materials for clay brick, shale, coal gangue and fly ash brick. Mainly in our local clay brick. According to the compressive strength of weathering resistance of radioactive material and qualified brick, according to the size deviation, appearance quality, efflorescence and lime burst into superior products, first-class products, qualified three quality grades.

- Q:When the coal-fired steam boiler is built, it is necessary to build a common red brick between the refractory bricks. May I ask what is the requirement for this common red brick?

- unnecessary

- Q:What is the proportion of lightweight fireclay bricks?

- The ingredients are mixed with water to form plastic mud or mud, by extrusion molding or casting molding, after drying at 1250-1350 Deg. C oxidation atmosphere sintering. The volume density of commonly used clay bricks is between 0.75-1.2g/cm3. In reality, the proportion is 1.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Price and High Quality MGO-C Brick for Steel Ladle

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches