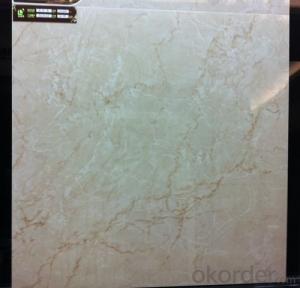

Glazed Porcelain Floor Tile 600x600mm CMAX-S6658

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information:

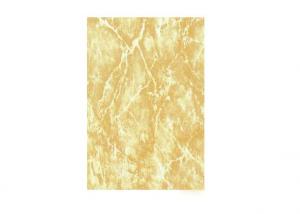

Tile Type | Glazed Porcelain Tile, floor tiles |

Certificate | ISO13006, ISO9001 |

Finish | Matte Finish, Lapato Finish, Rough Finish |

Size | 60x60 mm |

Selection Range | Several Colors available |

Features:

1) Unique natural sandstone image designs and exclusive quality;

2) Used for indoor & outdoor wall and floor decorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof, alkali-proof, durable

4) Material: porcelain

5) Basic size: 600x600x9.8mm, 100x600mm, 150x600mm, 300x300mm, 300x600mm available based on clients’ requirements;

6) Available dimensions

Material | Porcelain |

Dimension | 600x600x9.8 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The glazed porcelain tile is widely used for interior house flooring, hotel lobby flooring, exclusive brand showroom, clubs villas as well as other public sites.

We could go with OEM model, making 2nd production based on client’s requirement;

We could offer flexible service on shipment and better support on payment term;

Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as 2nd production and final package.

Specification and technical parameter:

· Matte Finish, Lapato Finish, Rough Finish

· Water absorption:<0.1%< span="">

· Anti-Resistance: R10

· Delivery Time: within 15~20 days after order confirmation.

· Package standard: 4pcs/carton, 40 Cartons/pallet, 32 Kgs/Carton.

- Q:i have a tile back splash that runs all along my counter including behind my sink and behind my stove. it is a small 1 tile, and i‘m pretty sure it‘s original to the house (40‘s) so it‘s getting kinda grimy. no matter what i do to clean it, it‘s so tough, because of kitchen grease and splatter. the grout isn‘t sealed so it absorbs stains. i keep seeing people say sprinkle baking soda on tile, let it sit, and then clean with vinegar, which would be great if this was a floor, but its a wall, so if there are any solutions, that would be great. natural preferred. i really don‘t want to replace this. painting it is an option, so suggestions on paint for tile would be appreciated as well.

- magic erasers are great for this sort of thing. if it's ceramic tile they sell this stuff that works really good call tile guard. use apply a thin coat to the entire area (grout included) let it dry and wipe off with a damp sponge. this also is a good way to clean your grout. regardless if it's on the floor or being used as a backsplash.....I wouldn't suggest painting ceramic tile if doesn't work and the paint won't stick.

- Q:Our kitchen isn‘t that big and I hate the tile. My fiance says it‘s a huge big deal to remove the tile but not so hard to put new tile in.About how much does it run to remove tile, say from the average size kitchen.... it‘s about 7 foot by 18 feet.

- It should only cost about as much a sledge hammer costs. And you don't even need that big of one. Other than that just go in and hit it with the sledge and it will come up.

- Q:The bottom row of tiles on my roof are loose.Depending on the weather(wind) I have to move the tiles back every 3 weeks as they are slipping down.How do I fix this without ripping up all the tiles just to nail down this one row?I do not have a gutter.

- If they are the newer cement tiles, I would try a small cement drill, about the size of a 16 penny nail. Try to gently drill a hole in the tile where you want to nail it to the roof. Or use screws that don't rust. Don't nail or screw down to the tile, that will break it. You just want the nail to hold the tile in position. If they are the older mission tiles, made of clay, the same might work. But they are very brittle and may need a wood support shaped the same as the tile to put under before drilling.................JJJ

- Q:we had our bathroom redone, it looks great but the guy that did it got some grout on one of the decorative tiles, where it shouldn‘t be. Is there a way to get the grout off ?

- First if your unhappy the tile man should be called to do this. But if you feel you can do it yourself there are a couple ways to do it. If it happens to be a raised or relief style deco use a pc of wood. A small dowel sharpened to a dull point can be used to gently dig out the grout. If its a flat deco tile, scrape off excess with a flat pc of wood or plastic. Never use metal since it can leave a permanent mark on tiles. Fine hazes you can start with a dry rag and work up to a white nylon pad scrub with. When doing a rag or nylon pad do this dry, no water. Water helps reintroduce the grout to the tile. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:CAN I LAY TILE WITH NO GROUT LINES?

- The other Steve is correct. Tile is designed specifically to be grouted, most importantly to keep dirt, etc. out of even the most minute space if you BUTT them together, beyond that aesthetics is another purpose. You can create a grout line as thin as 1/8 inch. The issue is in the bonding agents of the grout, and it's intended purpose. All that said however CAN is certainly something valid. Will it remain a valid/viable installation? Doubtful. Since you don't add detail about the WHY of your notion, it's difficult to assess the issue. It would seem as an assumption that you might be happier with a smooth, seamless surface, which you wouldn't get by butting tiles with no grout lines either. Steven Wolf Thousands of sq. ft. of tile

- Q:i going to tile my whole house both floors bath room and all with the same tile it is a 20x20 tile diagonally where should i start and does it really matter where ?

- Start doing the largest area and do a 1/2 tile on the out side wall. All interior walls are supposed to be layed out to the out side and be square. Now if you have a long visible hall way near by, you may want to split that to get a good look at it from there. Its hard to positively say with out seeing it. I could visualize it then. Since this is a diagonal you cant control to much where the tiles land. If it were a straight lay, you d have a bit more control as to the layout. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:How to calculate the loss of tiles

- The loss rate of the block surface is calculated according to the fixed standard. Ordinary tile loss rate of 3%, such as interior wall tile wall. Special tile loss rate of 2%, such as marble walls.

- Q:12x12 ceiling tile are loose and sagging

- it can be a job.look in the ceiling,there should be tie wires holding the frame of the tiles up.they may need to be adjusted.to get the ceiling flat you will need to pull a string from one end to the other of the ceiling or use a laser

- Q:What is the standard water absorption of tiles?

- According to China's national standards for testing tiles, tiles according to the different water absorption, divided into porcelain brick (water absorption E ≤ 0.5%), fine stoneware tile (water absorption 3% ≤ E ≤ 6%), stoneware brick (water absorption 6 % ≤ E ≤ 10%), ceramic brick (water absorption of 10% or more) and so on. The test method should be tested on the back of the brick body. The moisture absorption of the tiles is related to the breaking strength, abrasion resistance and gloss performance. Generally speaking, the lower the water absorption of tiles, the better the tiles, the higher the product strength, wear resistance and gloss performance is better, the product is not prone to cracking or peeling. And high water absorption of the tiles after the thermal expansion and contraction will lead to tile surface cracks and the overall tile peeling, especially in the choice of toilet paving tiles more attention to this problem. To determine the size of the water absorption also has a simple method, the water absorption rate, also known as seepage rate, the simplest test method is to drop some water on the tile to do the experiment, after a few minutes, wipe the tile surface of the water, if not left any Traces, to prove that the water absorption of tiles is very low. If you leave the water mark tiles discoloration, then the ceramic tile water absorption is higher.

- Q:the tile is like a plastic what can i use to renstall the tile it is on the wall in the shower how long do i have to let the wall dry before putting tile back up and how long will i need to let it dry before using the shower again

- Yes, you need to have a dry underlayment before reinstalling tile. However, plastic tile in the shower sounds like bad news. If the underlayment is simply plaster wallboard, then you need to replace the shower walls. You need special board designed for wet applications; ask at your home center. You should really redo the tile with ceramic. An alternative is to install a fiberglass shower stall. These are much less labor intensive. If the underlayment is water-rated, then apply tile cement and stick the thing back on. Grout? You may need to redo that. It comes in many colors so you can get a good match. However, if one tile has popped off, then others are probably ready to go, so consider redoing the shower with a more permanent solution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-S6658

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products