Glass Wool Board 50kg/m3 china manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Glasswool Description

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Main Features

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

3. Scope of application

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc

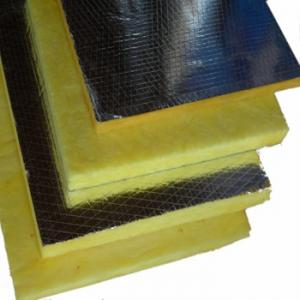

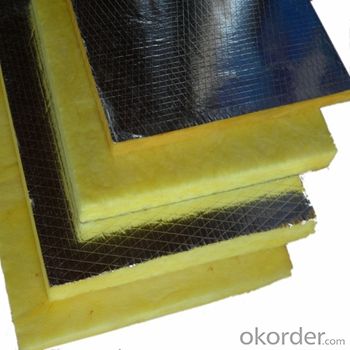

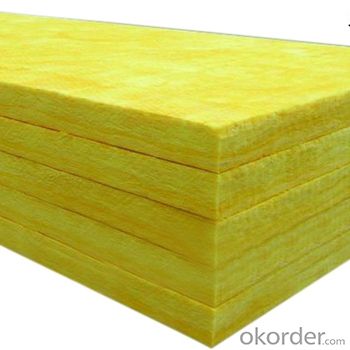

4. Glasswool Images

5. Glasswool Specification

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

6. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q:The difference between glass wool of 50mm and rock wool.

- Glass wool belongs to one of the glass fiber. machine-made fiber cotton wool molten glass fibrosis cotton material belong to glass fiber. type, bulk density, low thermal conductivity, thermal insualtion, acoustic insualtion, anticorrosion, stable chemical performance. Rockwool is also called mineral wool. Use Guangde Shida rock wool and mineral raw materials to make fluffy short fine fibers. Basalt rock wool, pyroxenite, dolomite, iron ore, bauxite can be used to make matrix fiber by going through high temperature melting process and fibrosis.

- Q:Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They are completely different products, and put it in a simple way, glass wool is made of glass, rock wool is made of stone,

- Q:What properties does glass wool felt have?

- Glass wool felt is a formed coiled material aiming to meet the needs of large-scale paving work. Besides its thermal preservation and thermal insualtion functions, it is also equipped with excellent shock absorption and sound absorption and noise absorption for low and medium frequency noise and vibration noise in particular, which is conducive to reducing noise pollution and improving common environment. This material can be cut freely based on needs during construction, which is mainly used as shock insulation, sound absorption and noise supression for interior architecture, muffler system, vehicles, refrigeration equipment and household appliances, and the effect is desirable. Glass wool with aluminum foil veneer has a strong thermal radiation resistance as well, which makes it a superb lining material applied in high temperature workshops, control rooms, inner wall of machine rooms, compartments and flattops.

- Q:Which one is more enviroment friendly, glass wool mat or rock wool sound insulating block?

- At present, low-carbon and environmental protection is widely promoted and glass wool is definitely more environment friendly than rock wool.

- Q:What is the density of high-temperature glass wool ?

- Sound absorption characteristics of glass wool depends on its thickness and density as well as overlay of pavement materials and structure. When applied to practical situations, we should also take into consideration of the cost, appearance, fireproof property, moistureproof, dust, anti-aging.

- Q:Is centrifugal glass wool board suitable for home use?

- A large number of people think that glass wool boards are harmful and that it will cause itch when contacting with the skin. And the effect is not obvious used in the surface, so it is generally used in the wall sandwich. They are harmless for wool boards have been checked, and only those which have passed the national inspection are allowed to be sold for home use. But do not use it in the surface as it is fiber products.

- Q:What is the thermal insulation material of glass wool?

- It is a cotton-like material which has advantages of low thermal conductivity, chemical stability, good sound absorption. The glass wool is an inorganic fiber which has a excellent welding performance. Glass wool which is a man-made inorganic fiber fiberizes melten glass, it is a insulation material that has advantages of corrosion resistance, thermal insulation and small bulk density. I tell you that it belongs to glass in terms of chemical composition: The thermal insulation material, glass wool belongs to glass fiber.

- Q:What are the differences between glass asbestos and glass?reinforced?plastics?

- Asbestos also known as "mountain cloth" is a commercial term that refers to silicate mineral products with high tensile strength, high flexibility, heat resistance, and chemical corrosion, electrical insulation as well as spinnability. It is the general term of natural fibrous silicate minerals. It includes two categories, a total of six kinds of minerals(serpentine asbestos, hornblende asbestos, actinolite asbestos, antholite asbestos, amosite asbestos, tremolite asbestos, etc.) Asbestos are made of fiber bundles, while fiber bundles are composed of long and narrow fibers which can be separated from each other. Asbestos, with properties of highly fire resistance, electrical insulation and thermal insulation, are important fireproofing, electrical insulation and thermal insulation materials. Glass?reinforced?plastics(FRP) also known as GRP, are fiber-reinforced plastics which generally refers to the matrix of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin. Reinforced plastics, with glass fiber or its products as reinforced materials, refer to glass fibre reinforced plastics or glass?reinforced?plastics. Due to the different varieties of resin, there are polyester glass?reinforced?plastics, epoxy glass?reinforced?plastics, and phenolic aldehyde glass?reinforced?plastics. They are light and rigid, non-conducting, and corrosion-resistant. They have high mechanical strength, low recycling rate. Machine parts, cars and Ship hulls made of steel can be replaced by them.

- Q:What is the uses of aluminum foil glass wool felt?

- Roll glass wool felt is coiled materials for large area coverage. It is not only thermal-insulating, but also can reduce shock and absorb sound,especially the medium and low frequency noise. It can help reduce the noise and improve the working environment. This material can be tailored based on the actual needs, mainly used for architectural indoor, muffler systems, transportation, refrigeration equipment, damping, sound absorption, noise reduction for the household appliances. Glass wool felt overlaid with aluminum foil has strong thermal radiation resistance. It is good lining material for high temperature workshops, control room, inner walls of machine room,compartment and flat top.

- Q:What are the functions of the thermal insulation glass wool board?

- Glass wool insulation materials are medium and low temperature thermal insulation materials, thus they are generally used in civil and cryogenic pipeline with the temperature of -120 ℃ -400 ℃. They can be used for thermal insulation and sound absorptionin in fields of construction, petrochemical, electric power and metallurgy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Wool Board 50kg/m3 china manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords