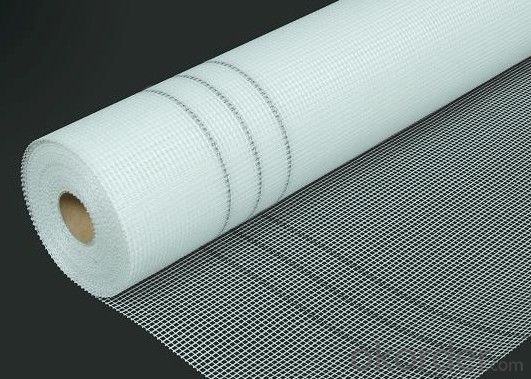

Glass Fiber Reinforced Concrete Sheet/well Fiber Glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | EW7532 |

| Application: | Wall/Roof covering Cloth | Weight: | 250 g/m2 | Width: | 900-1600mm |

| Weave Type: | Plain Woven | Yarn Type: | E-Glass | Alkali Content: | Alkali Free |

| Standing Temperature: | 300°C | Color: | White | Certificate: | ISO9001 |

| Advantage: | waterproof | Length per roll: | 500m | Thickness: | 0.18mm |

| Port: | Any Chinese port | Raw material: | fiberglass yarn |

Packaging & Delivery

| Packaging Details: | Cartons loaded on pallets |

| Delivery Detail: | 30 days after receiving the deposit |

Application

1. All types of thermal insulation and heat protection.

2. Welding blankets and fire curtains.

3. Expansion joints.

4. Basic cloth for coatings and laminations.

Specifications

glass fiber reinforced concrete

Firm mesh and good glue

fiberglass mesh manufacturer

| Fiberglass mesh grid component | 1.glass fiber woven fabric as substrate |

| 2.macromolecular anti emulsion coating | |

| The adventage of fiberglass mesh | |

| 1. good alkali resistance | |

| 2. flexibility and latitude to the high tensile strength | |

| 3. good chemical stability, high strength, light weight | |

| 4. good dimensional stability | |

| 5. strong impact resistance | |

| 6. pest control, fire protection, thermal insulation | |

| 7. other features | |

| Fiberglass mesh usage | |

| 1. wall reinforcing material | |

| 2. reinforced cement products | |

| 3. internal and external wall insulation | |

| 4. granite, marble, mosaic special mesh back paste network | |

| 5. waterproof cloth, asphalt roofing | |

| 6. reinforcing materials of plastics, rubber products | |

| 7. fire board | |

| 8. the grinding wheel base | |

| 9. highway pavement with geogrid | |

| 10. building sealing tape |

Our Services

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs to answer all your inquiries.

3. All our products have 1-year warranties.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.

- Q:whether the sound insulation is asbestos good or the glass wool good?

- Because the main function is the fireproofing), sound absorption cotton belongs to asbestos, but match up with the installation (glass fiber cloth, and we in real life (in fact, we need the material with good sound insulation

- Q:What is the difference between anti-high temperature glass wool and ordinary glass wool?

- High-temperature glass wool is made of lathy glass fibers without shot. Compared with other kinds of insulation materials, it will not be broken due to water or rain, and it can still remain its insulation properties unchanged after drying in the sun (Thermal insulation materials have hydrophobicity which doesn’t mean that the materials are not hydrophilic but means that the discharge capacity for absorbed moisture). High-temperature glass wool is a thermal insulation material that can resist high temperature with its lightweight, lasting durability and excellent thermal insulation property, the material that is made up of uniform and slender and elastic glass fibers as well as special high-temperature adhesive. The outer protective layer of thermal insulation structure can use galvanized iron sheet based on specific circumstances. Application of high-temperature glass wool: It is widely used in equipment and pipelines of electric power, petroleum, chemical industry, light industry, metallurgy and other industries, serving as the thermal insulation.

- Q:What are the differences among glass wool, rock wool and mineral wool?

- Glass wool: The main raw material is glass, the fire rating of which is A-level, and the heat conductivity coefficient is 0.037, the shrinkage temperature is around 270 degrees. Uses: It has a significant cold insulation performance. Rock wool: The main raw material is basalt, the fire rating of which is A-level, and the heat conductivity coefficient is 0.040, the shrinkage temperature is around 730 degrees. Uses: It can be used in high-end engineering projects such as construction, shipbuilding, petrochemical ones. Mineral wool: The main raw material is slag, the fire rating of which is A-level, and the heat conductivity coefficient is 0.044, the shrinkage temperature is around 680 degrees. Uses: It can be used as filling and thermal insulation materials for curtain walls.

- Q:What properties does glass wool felt have?

- It has better insulation properties.

- Q:If rock wool board and glass wool are used in enclosed stone curtain walls, which one is better?

- The meaning is actually same, but popularly it is called rock wool, while glass wool is adopted in actual use.

- Q:Glass wool products can be used for insulation layer

- Glass wool preservative

- Q:Glass wool can be used at zero degrees

- Ultra-fine cotton resin products, -120 ~ 400 ℃

- Q:How much is the unit weight of thermal insulation glass?wool?boards at least? How much is the unit weight of sound absorption glass panels?

- Sound-absorbing boards must be more than 80K at least, we use boards of 96K.

- Q:Glass wool 159 * 70 What does it mean

- Glass wool pipe specifications 159 refers to pipe diameter of 70 mm.

- Q:What are the applications of centrifugal glass wool board?

- Centrifugal glass wool board is board product with a certain intensity which is made by curing centrifugal glass wool. Whether in high or low temperature environment, it can maintain good heat insulation and sound absorption properties, mainly used for interior wall compartment in advanced architecture, compartment, ceiling, heat conservation for iron sheet air duct or aie bellow, sound absorption and noise reduction for studio, machine room and other places.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Fiber Reinforced Concrete Sheet/well Fiber Glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords