Geomembrana 3 mm of New LDPE Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrana 3 mm of New LDPE Made in China

Description Of Geomembrana 3 mm of New LDPE Made in China

The plastic film is used as the material of the plastic film as the anti - material, and the material of the non - woven fabric is made from the non - woven fabric. Its anti - permeability performance depends mainly on the anti - leakage performance of plastic film.

The main mechanism is conducive to the stability of composite geomembrane and a protective layer to plastic film is not permeable partition dam water leakage passage, to the greater tensile strength and elongation under pressure and adapt to the deformation of the dam; and non-woven fabric is also a polymer short chemical fiber material, formed by acupuncture or thermally bonded, has higher tensile strength and elongation, combined with plastic film, not only increases the tensile strength of plastic film and anti puncture capability and due to the non-woven surface roughness, increasing the coefficient of friction of the contact surface. At the same time, they have good corrosion resistance, not afraid of acid, alkali, salt erosion, the use of long life.

Main Features of Geomembrana 3 mm of New LDPE Made in China

Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane

Applications of Geomembrana 3 mm of New LDPE Made in China

Low density polyethylene geomembrane for transport facilities: foundation reinforcement for the road, culvert seepage control

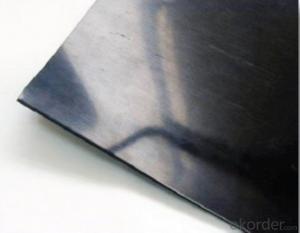

IMages of Geomembrana 3 mm of New LDPE Made in China

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:How do geomembranes contribute to erosion control in highway and road construction?

- Geomembranes contribute to erosion control in highway and road construction by providing a barrier between the soil and the elements. They prevent water from infiltrating the underlying soil, which helps to maintain the stability of slopes and embankments. Additionally, geomembranes aid in preventing the loss of fine particles from the soil, reducing sedimentation and erosion.

- Q:How do geomembranes contribute to erosion control in riverbanks?

- Geomembranes are impermeable liners made of synthetic materials that are used to prevent water seepage and erosion in riverbanks. They act as a barrier between the soil and water, effectively reducing the impact of flowing water on the riverbank. By preventing water from infiltrating the soil, geomembranes protect the stability and integrity of the riverbank, minimizing erosion and reducing the risk of landslides or collapses. Additionally, geomembranes also help to control the flow of water, redirecting it away from vulnerable areas and preventing concentrated flows that can accelerate erosion. Overall, the use of geomembranes in riverbanks plays a crucial role in erosion control by providing effective protection against the erosive forces of water.

- Q:How long can a mobile phone film use

- It depends on time you use your phone, if you play the game in a long time everyday, mobile phone film must have a short longevity. In general, a film can use two or three years. And, if you protect it well, you can use it until you do not want to use it.

- Q:Is waterproof geomembrane the same as EPDM?

- Not the same, different material

- Q:What is the typical width of a geomembrane in a mining application?

- The typical width of a geomembrane in a mining application can vary depending on the specific requirements of the project, but it is commonly found in widths ranging from 5 to 10 meters.

- Q:How do geomembranes improve water efficiency in golf course irrigation?

- Geomembranes improve water efficiency in golf course irrigation by acting as a barrier to prevent water seepage and loss. They effectively contain and retain water within the irrigation system, ensuring that the water reaches the desired areas and is not wasted through leakage or evaporation. This helps golf courses optimize water usage, minimize water runoff, and reduce the overall water consumption, resulting in improved water efficiency.

- Q:how to brush wallpaper basilemma

- First diluted the basilemma with pure water, and then follow the basilemma: Water =1: 1.5 brushing two times, wallpaper basilemma is developed from water-based high-tech materials, harmless to the human body and environment without adverse volatile gases. compared with conventional oil-based alkyd varnish, it effectively protect the indoor environment, and the life of oil alkyd varnish is longer three to five times. Wherein the moisture-proof film is used elastic molecular materials, and it in the case of micro-cracks in the walls is effectively protect your walls.

- Q:What are the prospects of electrothermal?film?

- Electrothermal film has been in the market for at least ten years. Currently the biggest problem is the large power consumption, even if you can cover the electric charge,original home wire diameters restrict the use of high-power electrical appliances. Another problem is power attenuation, the other problem is breaker tripping caused by electric leakage.

- Q:What are the design considerations for geomembranes?

- Some design considerations for geomembranes include the type of material used, thickness, strength, flexibility, chemical resistance, installation method, and expected lifespan. Other factors to consider are the site conditions, such as slope stability, temperature variations, and exposure to UV radiation. Additionally, the design should accommodate factors like water drainage, gas venting, and potential stressors like punctures or tears. Overall, the design should meet the specific requirements of the project, whether it is for containment, environmental protection, or erosion control.

- Q:Are geomembranes suitable for use in geothermal energy projects?

- Yes, geomembranes are suitable for use in geothermal energy projects. Geomembranes are flexible and durable materials that can effectively contain and control fluids, making them ideal for lining geothermal well pads and reservoirs. They provide a barrier against fluid leakage, prevent soil contamination, and help maintain the integrity of the geothermal system. Additionally, geomembranes have excellent thermal properties, which can contribute to the overall efficiency and performance of geothermal energy projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrana 3 mm of New LDPE Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords