Fused Cast Refractor Bricks for Glass Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Fused Cast Refractor Bricks for Glass Furnace

| Place of Origin: | China (Mainland) | Shape: | Brick, Customized | Material: | Alumina Block |

| SiO2 Content (%): | 16% | Al2O3 Content (%): | Remain | CaO Content (%): | 1.0% |

| Refractoriness (Degree): | 1770°< Refractoriness< 2000° | Model Number: | CXD-GGYZ11 | Brand Name: | |

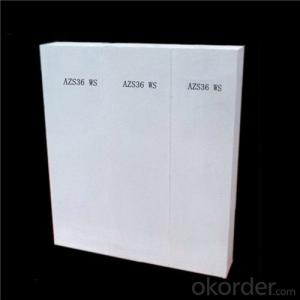

| Name: | fused cast azs refractor bricks | Type: | Manufacturer | Color: | White |

| Certificate: | ISO9001 | Sample: | Available | ZrO2: | ≥32% |

| Compress crushing strength: | ≥350mpa | 0.2Mpa Refractoriness under load: | 1700C | Contact: | Daisy |

Packaging & Delivery

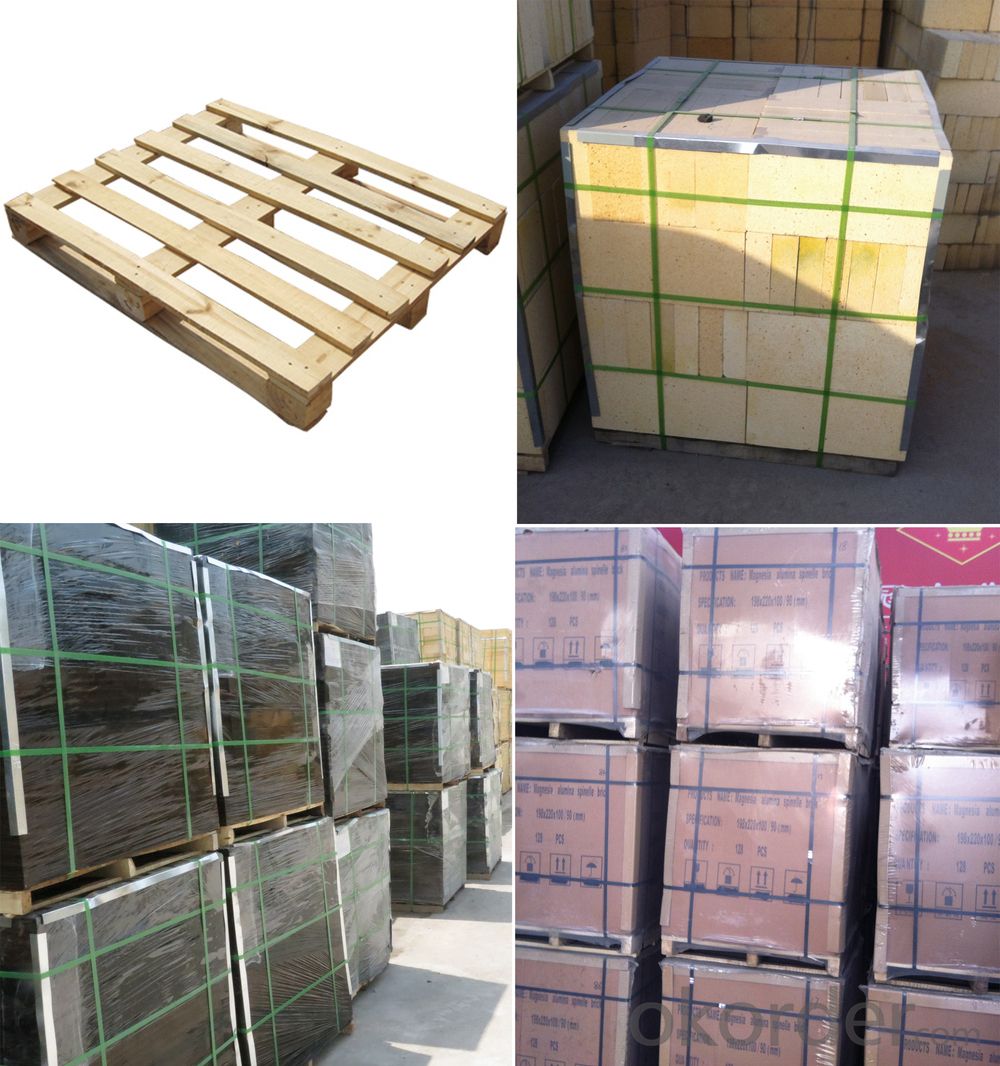

| Packaging Details: | Fumigated wooden pallet, plastic shrink film protected outside, then the straps. Finally make the wooden pallet (95*95cm, 95*100cm) , usually 1.5T per pallet, 20T per container , or as your requirements. |

| Delivery Detail: | within 20 working days after deposit |

Product Description

| Description of fused cast azs refractor bricks |

The fused cast azs refractor bricks are made of alumina powder, zirconia sand and additive etc.

| Applications of fused cast azs refractor bricks |

The fused cast azs refractor bricks are mainly used for Glass furnace tank

| Advantages of fused cast azs refractor bricks |

1. Good corrossion to glass liquid resistance

2. Low pollution

3. Good thermal shock resistance

4. High hot crush strength

| Physical and Chemical Indexes of fused cast azs refractor bricks |

| Item | Unit | Indexes | ||

| AZS-33 | AZS-36 | |||

| ZrO2 | % | ≥32 | ≥35 | |

| SiO2 | % | ≤16 | ≤14 | |

| Al2O3 | % | Remain | Remain | |

| NaO2 | % | ≤1.5 | ≤1.6 | |

| Fe2O3+TiO2+CaO+k2O | % | ≤2.5 | ≤2.5 | |

| Compress crushing strength | Mpa | ≥350 | ≥350 | |

| Exudationtemperature of glassphase | ℃ | >1400 | >1400 | |

| Anti Liquid glass erosion resistance | mm | ≤1.6 | ≤1.5 | |

| (1500℃*36h) | ||||

| Bulk density | Common casting | % | ≥3.4 | ≥3.5 |

| Inclined casting | % | ≥3.45 | ≥3.55 | |

| No piping casting | % | ≥3.7 | ≥3.8 | |

| 0.2Mpa Refractoriness under load | ℃ | 1700 | 1700 | |

Packaging & Shipping

Our Services

1. Quality assurance,CX REFRACTORY use high grade raw material. All products are ISO qualified.

2. Provide professional designing solution, field technical assitance and any other consulting.

3. Price advantage, provided by manufacturer directly,save much intermediate fees.

4. Professional and experienced service team, specialized in refractory production since 1986.

5. Large production capacity, short lead time of products.

6. 24*7 online service.

7. OEM service available.

FAQ

1. What’s the payment?

Usually T/T, others could be discussed.

2. When will you deliver the goods?

The delivery time will be determined according to the quantity of the order.

3. Do you provide samples?

Yes, samples are available.

4. How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

5. Do you accept OEM?

Yes, we can do OEM.

- Q:What's the use of refractory bricks?

- Refractory material of a certain shape and size.According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q:How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q:What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q:What material is good for refractory bricks?

- 1, silicon aluminum refractory bricks mainly include the following.(a) is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.(two) clay brick is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.(three) the mineral composition of high alumina refractory brick and high alumina refractory brick is corundum, mullite and glass phase. The raw materials are high alumina and sillimanite natural ore. They are also made of fused alumina, sintered alumina, synthetic mullite and calcined alumina in different proportions with clay. It is produced by sintering process. But the products are casting brick, brick, brick fused grain and unshaped refractory brick. High alumina refractory brick is widely used in iron and steel industry, non-ferrous metal industry and other industries.

- Q:What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q:Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- The temporary pollution in the process of tiling should be cleaned in a timely manner with a damp cloth.

- Q:Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- A cuboid with stone walls, with mud firing, mostly red, commonly known as "red brick", there are "blue brick". The size of China's standard clay bricks is 240 x 115 * 53mm. The purpose of this size is to ensure that the length and width of the bricks are 4:2:1 (including the width of the 10mm seam). The thickness of brick to brick brick due to multiple titles, length is 240mm, so the thickness of a brick wall called "24" wall thickness of brick and a half wall called "37" wall thickness is the half brick wall is also known as the "one or two wall". Use bricks online to compare some extreme jokes.

- Q:What are the forming methods of refractory materials?

- Casting molding is suitable for casting brick, electric melting brick and so on. And the machine press forming is the most widely used. The common refractory brick, clay brick and other sintered brick are adopted this method.

- Q:Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fused Cast Refractor Bricks for Glass Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords