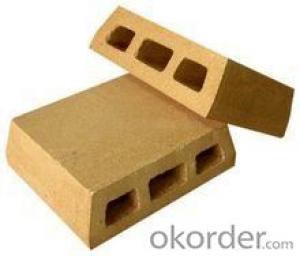

LOW CREEP ANDALUSITE BRICKS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Made from Mullite and andalusite as starting materials, the bricks are processed into shapes by moulding under high pressure and sintering are high temperature, with feature of lower impurity contents, low porosity ,low bulk density,strong strength at high temperature,steady bulk at high temperature,high thermal shock resistance and small creep rate,which are mainly used for HBS.

Brand Index | LHZ-150 | LHZ-145 | LHZ-140 | LHZ-135 |

Al2O3, % ≥ |

|

|

|

|

Fe2O3, %, ≥ | 1.0 | 1.0 | 1.3 | 1.3 |

AP, % ≤ | 1810 | 1810 | 1790 | 1790 |

BD, g/cm³ ≥ |

|

|

|

|

Refractoriness, °C ≥ |

|

|

|

|

CCS, MPa ≥ | 65(55) | 65(55) | 70(60) | 70(60) |

0.2MPa RUL, °C ≥ | 1650 | 1650 | 1630 | 1600 |

PLC(1500°C x 5h), % | 0~+0.5 | 0~+0.5 | 0~+0.5 | 0~+0.5 |

Thermal shock resistance, | 30 | 25 | 25 | 20 |

Creep rate, % ≤ | 0.8 (1500°Cx50h) | 0.8 (1450°Cx50h) | 0.8 (1400°Cx50h) | 0.8 (1400°Cx50h) |

Specifications

1,Low Creep andalusite brick

2,Resisting high temperature.

3,Great bulk density.

4,Low iron content.

- Q:What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

- Q:How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q:What's the weight of the refractory bricks?

- Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms

- Q:What material is good for refractory bricks?

- No definite answer can be given, because any furnace is not made of only one refractory brick and needs a different fire brick to be used with each other.

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q:What are kiln bricks?

- Refractory materials are generally divided into two kinds, namely unshaped refractory and shaped refractory. Unshaped refractory castable is also called, is composed of a variety of aggregate or aggregate and one or more adhesive powder particles, and must use one or more liquid with stirring, has strong liquidity. Refractory materials generally refers to the shape of a refractory brick, standard rules, can also according to need to be cut when the temporary processing.

- Q:Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- The temporary pollution in the process of tiling should be cleaned in a timely manner with a damp cloth.

- Q:What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q:Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Not always。Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q:Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LOW CREEP ANDALUSITE BRICKS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords