Low Weight Bricks

Low Weight Bricks Related Searches

High Five Stainless Steel Prop High Quality Solar Inverter High Temperature Clear Plastic Sheet High Voltage Solar Inverter Stainless Steel Peg Board Best Quality Roofing Felt High Intensity Desk Lamp High Efficiency Hvac Systems High Rupturing Capacity Fuse High-Pressure CompressorHot Searches

Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Price Of Shipping Containers For Sale Stock Price For Aluminum Air Pump For Aquarium Price Used Foam Board Insulation For Sale Bags Of Cement For Sale Types Of Temporary Side Panels For Cement Deck Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Solar With Inverter Price Pedestal Fan With Water Spray Price Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel High Mast Light Price List Solar High Mast Light Specification Price For Stainless Steel ScrapLow Weight Bricks Supplier & Manufacturer from China

Okorder.com is a professional Low Weight Bricks supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Low Weight Bricks firm in China.Hot Products

FAQ

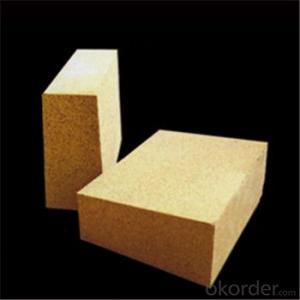

- Yes, insulating fire bricks are suitable for thermal insulation in boilers. They have high thermal conductivity and can withstand high temperatures, making them an effective choice for insulating the walls and floors of boilers. Their ability to retain heat helps in improving energy efficiency and reducing heat loss, ultimately enhancing the overall performance of the boiler system.

- Indeed, insulating fire bricks are suitable for insulating hot water tanks. Their superior thermal insulation properties deem them an optimal selection for such purpose. By utilizing these bricks, heat loss from the hot water tank can be efficiently prevented, consequently prolonging the water's temperature retention. Furthermore, these bricks exhibit exceptional durability and can endure high temperatures without fracturing or shattering, rendering them a dependable option for hot water tank insulation.

- Certainly, cement plants can utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are widely employed in thermal insulation-demanding industries. Within cement plants, they can find diverse applications, including kiln lining, furnace lining, and other equipment operating at high temperatures. These bricks effectively decrease heat dissipation, enhance energy efficiency, and maintain stable and regulated temperatures during cement production. Furthermore, insulating fire bricks possess a lightweight nature and exhibit low thermal conductivity, rendering them an optimal selection for insulation purposes within cement plants.

- Difference between inorganic insulation material and organic thermal insulation material

- The main difference between inorganic insulation materials and organic thermal insulation materials is that the types of insulation materials are different:1, inorganic insulation materials, including glass wool, rock wool, expansion perlite, micro nano insulation board;2, organic insulation materials are mainly polyurethane foam, polystyrene board, phenolic foam and so on.

- Insulating fire bricks lack resistance to oil or chemical spills in general. Their main purpose is to endure high temperatures and offer insulation in various settings, such as furnaces, kilns, and fireplaces. Despite their efficient handling of heat and thermal shock, these bricks are typically composed of materials like clay, alumina, or silica, which do not possess inherent resistance to oil or chemicals. In the event of exposure to oil or chemical spills, these bricks may absorb the substances, potentially resulting in degradation or diminished performance over time. Hence, if oil or chemical resistance is a crucial requirement, it is advisable to explore alternative materials explicitly designed for such applications.

- Yes, insulating fire bricks are suitable for use in the construction of incinerators. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. Incinerators operate at extremely high temperatures, often exceeding 1000 degrees Celsius, and require materials that can withstand these intense conditions without cracking or deteriorating. Insulating fire bricks are made from lightweight refractory materials, such as ceramic fibers or lightweight aggregates, which have low thermal conductivity. This means that they are able to effectively insulate the incinerator, preventing heat from escaping and ensuring maximum energy efficiency. The insulation properties of these bricks also help to maintain a consistent temperature inside the incinerator, which is crucial for proper combustion and waste disposal. Furthermore, insulating fire bricks have excellent resistance to thermal shock, allowing them to withstand repeated heating and cooling cycles without damage. This is crucial in incinerators, where the temperature can fluctuate rapidly during the burning process. The bricks' ability to withstand thermal shock ensures their durability and longevity in this high-temperature environment. In addition to their insulation and thermal shock resistance, insulating fire bricks also offer other benefits for incinerator construction. They are lightweight, making them easier to handle and transport during the construction process. They can also be easily cut or shaped to fit specific designs or requirements, allowing for flexibility in the construction of incinerators. Overall, insulating fire bricks are an ideal choice for the construction of incinerators due to their high-temperature resistance, insulation properties, thermal shock resistance, durability, and ease of use. They provide a reliable and efficient solution for containing and maintaining the intense heat generated in incinerators, ensuring safe and effective waste disposal.

- Insulation brick should pay attention to external walls?

- Before the tile is adhered, the water spraying device is applied to spray the wet water on the adhered base layer so as not to flow better.