65% Al2O3 Min High Alumina Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

65% Al2O3 Min High Alumina Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

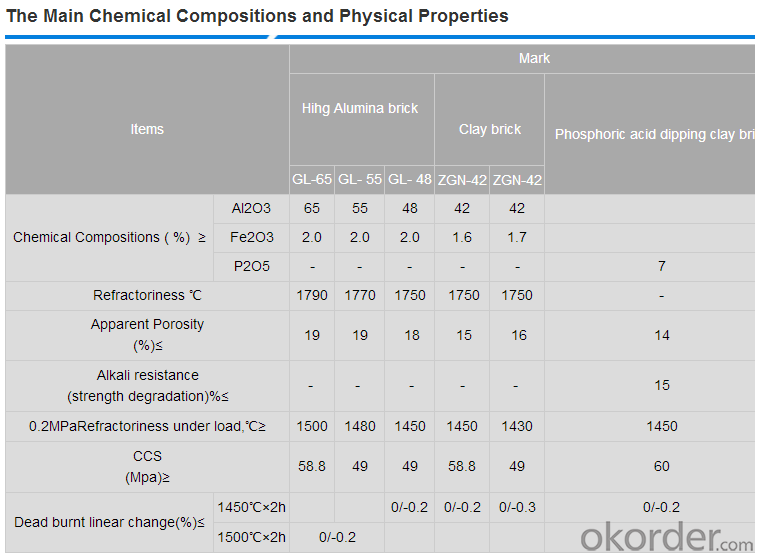

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

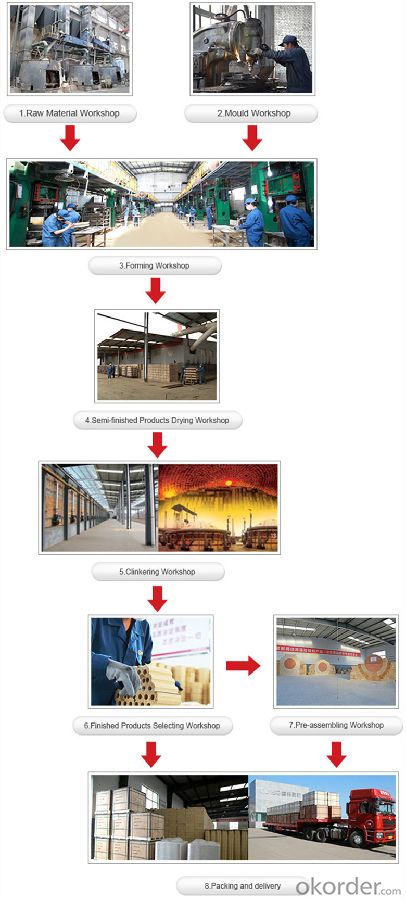

Produce Processing

- Q:Can insulating fire bricks be used in the insulation of boilers?

- Yes, insulating fire bricks can be used in the insulation of boilers. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in boilers to minimize heat loss and increase energy efficiency.

- Q:Can insulating fire bricks be cut or shaped as needed?

- It is possible to cut or shape insulating fire bricks according to one's needs. These bricks are manufactured using lightweight materials like ceramic fibers and refractory materials, which make them more easily cut and shaped compared to traditional dense fire bricks. Cutting them can be done effortlessly using a saw or a specialized cutting tool, while shaping can be achieved through grinding, sanding, or chiseling. The ability to cut and shape them gives the advantage of custom fitting the insulating fire bricks to specific applications or structures. However, it is crucial to emphasize that precautions must be taken for safety while cutting or shaping the bricks. Wearing protective goggles, gloves, and a dust mask is essential in order to prevent inhaling any hazardous particles.

- Q:Is it possible to paint or coat insulating fire bricks?

- Indeed, it is feasible to apply paint or coat insulating fire bricks. Nevertheless, it is imperative to utilize a type of paint or coating that can endure elevated temperatures, given that insulating fire bricks are intended for usage in exceedingly hot surroundings. Ordinary paint or coatings may not be appropriate since they can combust or deteriorate under high temperatures. It is advisable to employ specialized high temperature paint or coatings that have been specifically formulated to withstand the intense heat of insulating fire bricks. Typically, these types of paint or coatings possess a resistance to high temperatures of several hundred degrees Celsius or greater. Moreover, it is crucial to adequately clean and prepare the surface of the bricks prior to applying any paint or coating to ensure optimal adhesion and durability.

- Q:Can insulating fire bricks be used in reheating furnaces?

- Yes, insulating fire bricks can be used in reheating furnaces. They are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in heating and reheating applications.

- Q:What is the price of refractory bricks?

- Insulating brick is a refractory brick often used in kilns to reduce the heat loss of kilnsSo as to ensure the practical efficiency of kiln and bring more benefits.There are many kinds of thermal insulation bricks, and there are many refractory manufacturersAs to how much bricks should be paid, a detailed consultation should be made to the refractory bricks manufacturerHave some understanding of the properties, technologies, raw materials and so on, and make a decisionDifferent types of insulation brick prices are different, the price is relatively cheap, lightweight clay insulation brick 1The market price is 1.3 yuan a pieceThe price of mullite heat preservation brick 0.8, the market price of 4.62 yuan a pieceDepending on the area, the price of insulating bricks will fluctuate somewhat

- Q:Can insulating fire bricks be used for insulation in smelters?

- Indeed, insulation in smelters can be achieved by utilizing insulating fire bricks. These bricks are purposefully crafted to endure elevated temperatures and offer exceptional thermal insulation. Composed of lightweight refractory materials with low thermal conductivity, they effectively retain heat and limit heat dissipation. As a result, they prove to be a perfect choice for smelters, where maintaining optimal temperatures is imperative for efficient metal smelting operations. Furthermore, insulating fire bricks possess resistance against chemical corrosion and mechanical strain, guaranteeing their longevity and appropriateness for use in demanding smelting settings.

- Q:Can insulating fire bricks be used for insulation in incinerators?

- Yes, insulating fire bricks can be used for insulation in incinerators. Insulating fire bricks are made from lightweight refractory materials and have high insulating properties, making them ideal for applications that require heat containment and energy efficiency, such as incinerators. These bricks have low thermal conductivity, which means they can effectively trap and retain heat within the incinerator, preventing it from escaping and improving the overall efficiency of the incineration process. Additionally, insulating fire bricks are resistant to high temperatures and can withstand the harsh conditions typically found in incinerators, making them a reliable choice for insulation purposes.

- Q:Are insulating fire bricks resistant to acids and alkalis?

- Insulating fire bricks are generally resistant to acids and alkalis, but the level of resistance can vary depending on the specific composition and manufacturing process of the bricks. Insulating fire bricks are typically made from materials such as alumina, silica, or a combination of both, which provide excellent resistance to high temperatures and thermal conductivity. These materials are generally chemically inert, meaning they do not react with acids or alkalis. However, it is important to note that some acids and alkalis can still cause slight degradation or corrosion over time, especially if they are highly concentrated or used at elevated temperatures. In such cases, it is advisable to consult the manufacturer's specifications or conduct specific tests to determine the level of resistance of the insulating fire bricks to the particular acids or alkalis in question. Overall, insulating fire bricks are a suitable choice for applications that involve exposure to acids and alkalis, but it is always recommended to consider the specific requirements and consult with experts or manufacturers to ensure the bricks will perform adequately in the intended environment.

- Q:Do insulating fire bricks require any special installation techniques?

- Yes, insulating fire bricks do require special installation techniques. These bricks are designed to provide excellent thermal insulation, which means they need to be installed properly to achieve optimal performance. Firstly, it is important to ensure that the installation surface is clean and free from any debris or moisture. This helps to create a strong and stable base for the bricks. Next, a suitable refractory mortar or adhesive should be used to secure the bricks in place. This mortar should be specifically designed for high-temperature applications and should be able to withstand the thermal expansion and contraction that occurs during heating and cooling cycles. During the installation process, it is crucial to pay attention to the joints between the bricks. These joints should be properly filled with mortar to prevent heat loss and maintain the insulating properties of the bricks. Additionally, insulating fire bricks should be carefully stacked and aligned to ensure a tight fit and minimize any gaps between the bricks. This helps to maximize the insulating effect and prevent heat leakage. Finally, it is recommended to consult the manufacturer's guidelines and follow their recommended installation techniques. Each type of insulating fire brick may have specific requirements that need to be followed for proper installation. Overall, insulating fire bricks do require special installation techniques to ensure their effectiveness and longevity. Following proper installation practices will help to enhance the thermal insulation properties of these bricks and optimize their performance.

- Q:What industries commonly use insulating fire bricks?

- Insulating fire bricks find widespread use in diverse industries that require high-temperature insulation. Some of the sectors that commonly utilize these bricks are: 1. Steel industry: Furnaces, kilns, and other equipment in steel manufacturing plants are lined with insulating fire bricks to enhance insulation, minimize heat loss, and optimize energy efficiency. 2. Glass industry: Insulating fire bricks are employed in furnaces and ovens where glass is melted and molded. They maintain high temperatures, minimize heat loss, and ensure consistent and efficient production. 3. Ceramic industry: Ceramic kilns and pottery ovens rely on insulating fire bricks for thermal insulation, which helps maintain the desired temperature for clay and ceramic products. These bricks conserve energy and optimize firing processes. 4. Cement industry: Cement kilns require efficient high-temperature insulation, achieved through the use of insulating fire bricks. They line the kilns, reducing heat loss and improving thermal efficiency. 5. Foundry industry: Foundries use insulating fire bricks to line melting furnaces and ovens for metal casting. These bricks retain heat, ensuring consistent and efficient metal melting. 6. Power generation industry: Boilers, furnaces, and incinerators in power plants benefit from the thermal insulation provided by insulating fire bricks. They prevent heat loss, improving overall power generation efficiency. 7. Petrochemical industry: Refineries and chemical processing plants rely on insulating fire bricks to line reactors, furnaces, and ovens. These bricks offer insulation against high temperatures and harsh chemical environments. 8. Pharmaceutical industry: Insulating fire bricks are used in pharmaceutical manufacturing facilities to line ovens and dryers. They enable precise temperature control and enhance energy efficiency. In conclusion, insulating fire bricks have wide-ranging applications in industries that emphasize the importance of high-temperature insulation for efficient and cost-effective operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

65% Al2O3 Min High Alumina Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords