Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

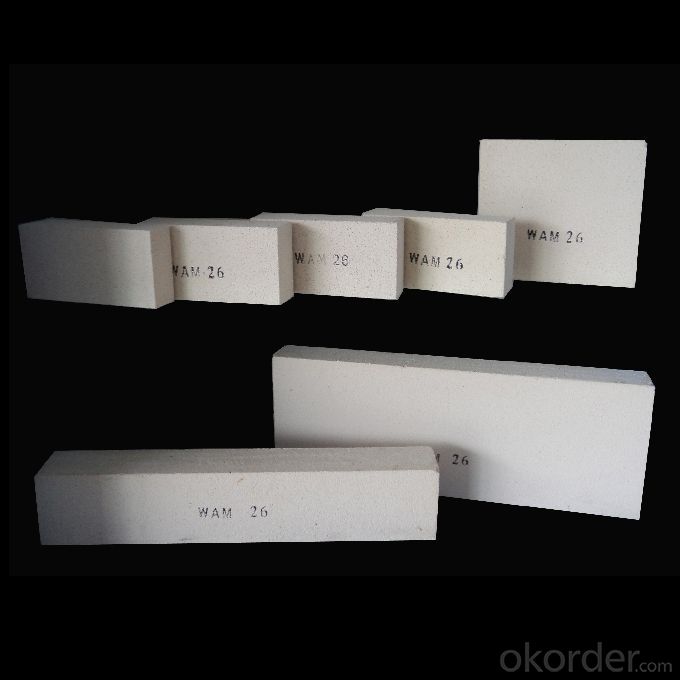

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q:How do insulating fire bricks help reduce emissions from heating equipment?

- Insulating fire bricks help reduce emissions from heating equipment by providing better insulation, which improves the efficiency of the heating process. This means that less fuel is required to generate the desired heat, resulting in reduced emissions of greenhouse gases and pollutants. Additionally, the insulation helps to maintain higher temperatures within the equipment, promoting more complete combustion and further minimizing emissions.

- Q:What is the recommended curing method for insulating fire bricks?

- The recommended curing method for insulating fire bricks is a gradual and controlled process known as air drying. After the bricks have been laid and mortared into place, it is important to allow them to dry naturally in order to prevent cracking or other damage. During the curing process, it is crucial to maintain a consistent temperature and humidity level. This can be achieved by gradually increasing the temperature over a period of several days while ensuring adequate ventilation. The bricks should be exposed to air circulation to facilitate evaporation of any moisture present in the mortar or within the bricks themselves. It is important to note that the curing process may take several weeks, depending on the size and thickness of the brickwork. Rushing the curing process by applying excessive heat or moisture can lead to thermal stress and ultimately compromise the integrity of the bricks. In some cases, pre-firing the bricks in a kiln may be recommended to remove any residual moisture prior to installation. This can help accelerate the curing process and ensure the bricks are thoroughly dried before being placed in service. Overall, the recommended curing method for insulating fire bricks involves gradual air drying, maintaining consistent temperature and humidity levels, and allowing ample time for the bricks to fully cure before exposing them to high temperatures. Following these guidelines will help ensure the longevity and performance of the insulating fire bricks.

- Q:What are the types of building blocks?

- Ordinary housing: building brick (clay brick), and non sintered brick (sand lime brick, fly ash brick, cement brick, etc.)

- Q:Do insulating fire bricks have a high insulation efficiency?

- Yes, insulating fire bricks have a high insulation efficiency. Due to their low thermal conductivity and high heat resistance, they effectively prevent the transfer of heat, thereby providing excellent insulation.

- Q:Is it necessary to use mortar when installing insulating fire bricks?

- Yes, it is necessary to use mortar when installing insulating fire bricks. Mortar is a crucial component in the installation process as it helps to bond the bricks together, ensuring a tight and secure fit. It also helps to create a strong and durable structure that can withstand high temperatures. Without mortar, the bricks may not be properly secured and could shift or become loose, compromising the integrity of the installation. Additionally, mortar helps to fill in any gaps or spaces between the bricks, providing insulation and preventing heat loss. Therefore, using mortar is essential for a successful and effective installation of insulating fire bricks.

- Q:What is the typical cost of insulating fire bricks?

- The cost of insulating fire bricks can vary depending on various factors like size, quality, and quantity required. Generally, prices per brick can range from $2 to $10. Nevertheless, it is important to note that these figures are approximate and actual prices may differ based on the source of purchase and specific project requirements. To ensure the most favorable deal, it is advisable to compare prices from different suppliers.

- Q:Can insulating fire bricks be used for sound insulation?

- Insulating fire bricks are primarily designed for thermal insulation in high-temperature applications, such as kilns and furnaces. While they do offer some level of sound absorption due to their porous structure, they are not specifically engineered for sound insulation purposes. Therefore, if your goal is to achieve effective soundproofing or noise reduction, it is recommended to use materials specifically designed for that purpose, such as acoustic panels, mineral wool, or other sound-absorbing materials.

- Q:Can insulating fire bricks be used in kilns?

- Indeed, kilns can utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures while offering exceptional insulation, rendering them highly suitable for kiln applications. Their low thermal conductivity plays a pivotal role in preserving the heat generated within the kiln, guaranteeing efficient and consistent heating. Furthermore, their lightweight nature facilitates effortless handling and installation in kilns. Moreover, they exhibit resistance to thermal shock, enabling them to withstand abrupt temperature fluctuations without succumbing to cracks or breakage. All in all, insulating fire bricks emerge as a dependable and efficient option for kiln usage.

- Q:Can insulating fire bricks be used in metal melting furnaces?

- Indeed, metal melting furnaces can utilize insulating fire bricks. Specifically tailored to endure high temperatures and offer exceptional insulation, these bricks prove to be an optimal selection for applications such as metal melting furnaces. These bricks possess a low thermal conductivity, which aids in heat preservation and diminishes energy usage. Furthermore, insulating fire bricks are lightweight, long-lasting, and capable of withstanding thermal shock, rendering them a fitting choice for the severe conditions experienced in metal melting furnaces.

- Q:How do insulating fire bricks compare to other insulation materials like ceramic fiber?

- Insulating fire bricks are generally denser and more durable compared to ceramic fiber insulation materials. While ceramic fiber offers excellent thermal insulation and is lightweight, insulating fire bricks provide better resistance to high temperatures and mechanical stress. Additionally, insulating fire bricks have lower thermal conductivity and higher compressive strength, making them suitable for applications that require long-term thermal insulation and structural support.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords