Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

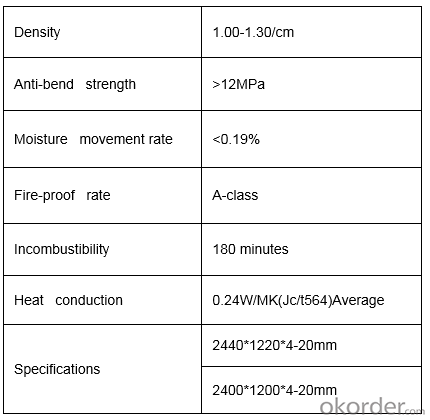

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q:What is the specific difference between the silicate board and the calcium silicate board?

- Later, the introduction of calcium silicate board in China, in the decoration industry also appeared in the "calcium silicate board." And explained: "silicon calcium board, full name is fiber reinforced calcium silicate board, it is made of siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, , Calcium, and the like. The other significant feature is that it is easy to reprocess, and it is not easy to handle, Like gypsum board that is easy to powder-like fragmentation. "

- Q:Living room light steel keel ceiling is gypsum board seal or calcium silicate board seal is better?

- Now the family is used in the gypsum board, and small-scale ceiling do not need to seal the wood floor.

- Q:External wall of calcium silicate board seams posted why the grid is also cracked

- First, whether the gap between the calcium silicate board (plate) is caulked with the caulking agent, because the outdoor long-term sun and rain, the reasons for thermal expansion and contraction

- Q:Calcium sulfate anti-static flooring and calcium silicate board What are the differences

- High-density calcium sulfate flooring is solidified from raw materials into calcium sulfate crystals, and the use of non-toxic bleached plant fiber as a reinforcement material through a pulse suppression process made. Covered with HDL melamine anti-static veneer, PVC, tiles, carpets, marble or natural rubber, plastic floor around the floor, the floor is generally used galvanized steel or aluminum foil.

- Q:Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- There are dust, waste gas, waste water pollution, calcium silicate board used lime, cement, quartz powder, chrysotile asbestos (carcinogens, most domestic enterprises are still used) and other raw materials, in the feeding, finished sanding, cutting process , Many companies ignore the dust pollution, dust removal capacity and capacity does not match, asbestos,

- Q:Calcium silicate board, asbestos volatile out of cancer problems, anxious?

- Calcium silicate board with cotton and cotton board, cotton board is made of asbestos and its associated products mixed with cement, quartz sand produced from the production and use of asbestos products have been banned in the world, asbestos was inhaled through the lungs Into the blood vessels to break the snow red blood cells and cause blood diseases and other diseases. Cotton-free calcium silicate board is mixed with cement and quartz sand in the original wood pulp fiber, autoclaved curing, is currently recognized as the most environmentally friendly building plate. You would like to buy environmentally friendly sheet but did not intend to buy the most dangerous materials, if the amount is huge, you can put a decoration company or material business claims for compensation, because asbestos products are not allowed for home decoration. For the whole family's health, it is recommended that you redemption of calcium-free calcium silicate board, because of technical barriers to the problem, the current domestic production of two cotton-free calcium silicate board enterprises are located in Guangzhou and Ningbo, And board, you can understand each other.

- Q:Tempered glass backdrop and calcium silicate board background wall which is better?

- At present, the art of artificial carved glass background wall is very popular with users.

- Q:Decoration problem: a calcium silicate board about how many customers want me to calculate the weight. The Trouble trouble trouble.

- A 1220 * 2440 calcium silicate board is about 3KG. Wrong, sorry To the thickness of 8MM board as an example: 122CM * 240CM * 0.8CM = 23814CM3 About 20KG

- Q:Do the TV backdrop, there is a part of the original window, now sealed with calcium silicate board.

- I suggest you finish the plaster to finish the plane with the wallpaper! Because the wallpaper has a special design to the TV wall is also a lot of choice! TV wall wallpaper and then use the process of plaster face!

- Q:Gypsum board, Etter board, calcium silicate board, mineral wool board physical properties of what is different, the kind of hotel for the ceiling is more appropriate?

- Usually with gypsum board it. The

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords