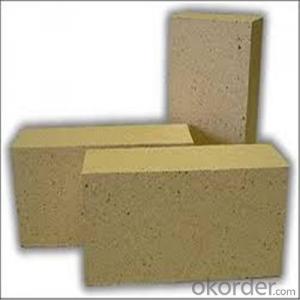

Low Porosity Fireclay Brick for Rotary Kiln,Fire Bricks for Boiler Mullite Insulating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Low Porosity Fireclay Brick for Boiler Mullite Insulating.Refractory Bricks for Rotary Kiln

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | a little | Al2O3 Content (%): | 38 | MgO Content (%): | a littile |

| CaO Content (%): | a little | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | a little |

| SiC Content (%): | a little | Model Number: | SX-mullite | Brand Name: | |

| Fe2O3: | 1 | bulk density: | 0.8-1 | RUL: | 1250 |

| C.C.S.(Mpa): | 1.2 |

Packaging & Delivery

| Packaging Details: | wood palet |

| Delivery Detail: | less than 50ton - 40days; more than 50ton - about 2month |

Specifications

mulli1.High compression strength

2.Top high-temperature capablility.

3.Excellent thermal stability.

4.Low thermal conductivit

Product Description for Low Porosity Fireclay Brick for Boiler Mullite Insulating.Refractory Bricks

Applications

1.Primary hot face linings

2.Back-up insulation for furnaces and kilns

3.Flue insulation

4.Sulphur recovery equipment

5.Hot blast stoves

Item | JM23 | JM26 | JM28 | JM30 | JM32 |

AL2O3(%) | 38-44 | 49-58 | 62-66 | 70 | 73 |

Fe2O3(%) | 1 | 0.9 | 0.8 | 0.7 | 0.6 |

Classification Temperature (°C) | 1350 | 1430 | 1500 | 1550 | 1600 |

Bulk Density (g/cm3) | 0.8-1 | 0.8-1 | 0.8-1 | 0.8-1 | 0.8-1 |

Reheating Linear Change (%) | 1250°C | 1400°C | 1500°C | 1550°C | 1600°C |

CT-30°CX 8H | -0.5 | -0.5 | -0.5 | -0.5 | -0.5 |

Cold Crushing Strength (Mpa) | 1.2 | 1.9 | 2.5 | 2.8 | 3 |

Modulus of Rupture (Mpa) | 1 | 1.2 | 1.4 | 1.6 | 1.8 |

Thermal Conductivity 350°C(W/m.k) | 0.15 | 0.26 | 0.33 | 0.38 | 0.43 |

Thermal Expansion 1000°C(%) | 0.46 | 0.47 | 0.48 | 0.48 | 0.49 |

Research and Development

We has expanded our research capabilities through the acquisition of a variety of test equipment, including Scanning Electron Microscopes, X-Ray Diffraction, Mercury Porosimetry, Thermo Gravimetric Analysis, Thermal Expansion, Optical Microscopy, Thermal Conductivity and Laser Analysis of Particle Sizing.

Our Research and Development Team also supports the Quality Control Department by helping with the characterization and testing of inbound raw materials, the key to building excellent products.

Precast Shapes

Our precast division has the capability to cast anything ranging from 5 lbs in weight to 25,000 lbs. We have two dry out ovens with a total combined capacity of 5,000 cubic feet and a top temperature of 800 degrees Fahrenheit. We have mobile capacity to dry out steel shell vessels to a temperature of 1500 degrees Fahrenheit. With refractory production and lab facilities in house, the precast facility has an enormous advantage to meet and exceed the goals of our customers that others cannot.

We pride ourselves in quality and promptness to satisfy the needs of our customers and produce it at lower cost. Please Call and let us help you with your problems at hand today.

Our Services

Timely ! Efficient ! Quality !

1. when you inquire our product or price, we will reply you within 8 hours.

2. Well-trained and experienced technician answer all your question in fluent English.

3. We provide the best after sales service. All our products have 1 year warranty period.

4. Offering the support to solve the problem in the selling or application period.

5. Competitive prices based on superior quality.

6. Guarantee samples quality same as your ordering production quality.

7. Adhere to the business philosophy "mutual trust, mutual benefit, mutual profit, faith oriented".

8. We believe "customer is God , quality is our unchangeable commitment".

Free sample of Fire Bricks for Boiler Mullite Insulating.Refractory Bricks for Rotary Kiln is as your request

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Porosity Fireclay Brick for Rotary Kiln,Fire Bricks for Boiler Mullite Insulating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords