Fireproof Fiber Cement Board Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Fireproof fiber Cement Board

The compressed machine is 14000 tons, So we can produce density over 1600kg/m3. 100% Non asbestos

Product Advantages:

Fireproof fiber Cement Board

Headerboard high density fiber cement board is 100% free of asbestos. The compressed machine is14000tons. So we can produce density over 1600kg/m3.Thickness from 4mm-30mm, Standsize is 1220*2440, size can be customized according to your requirement.

The production line was introduced from Germany. There are total two production lines now. Production capacity is 20 million square meters per year. We can send you boards earlier than other supplier.

Main Product Features:

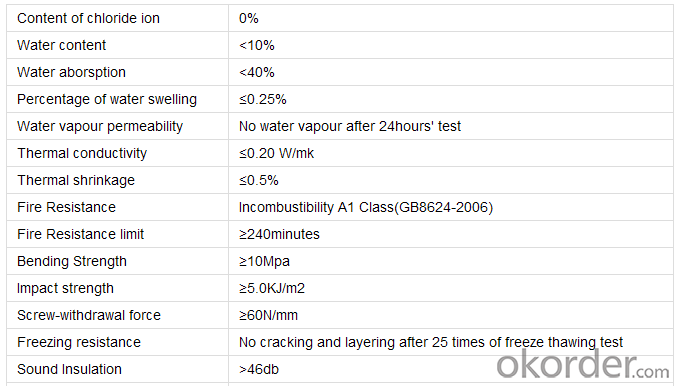

Product Name | Fireproof fiber Cement Board |

Raw Materials | Cellulose Fiber, Quartz Sand, Portland Cement |

Standard Size | 1220X2440MM / 1200X2400MM |

Maxium Width | 1250MM |

Maximum Length | 4880MM |

Thickness | 4-30MM |

Density | 1.5-1.7G/CM3; 1.2-1.4G/CM3 / 1.4-1.5G/CM3 |

Wet Expansion | ≤0.23% |

Water Absorption | ≤25% |

Incombustibility | Incombustible Class A1 |

Water Penetration | Back side without water drop after 24 hours |

Flexural Strength | Air dried condition: ≥18; Saturated Condition: ≥14 |

Radioactivity | Decorative materials Class A |

Frost Resistance | No layers and no cracks after 25 cycles under freezing and thawing |

Asbestos | 100% free of asbestos |

Certification | ISO, CE, SGS |

Packaging | Standard wooden pallet |

Trade Terms | FOB, CNF, CIF |

Payment Terms | T/T, Irrevocable L/C at sight |

Delivery Time | Within 15 days if stock not available |

Main Characteristic | Environmental friendly materials |

Excellent Strength and toughness | |

Waterproofing and fireproofing | |

Antisepsis and moth-proofing | |

Good acoustic insulation and weather resistance | |

Good thermal and heat insulation | |

Durability and long lifetime | |

Application | Exterior decoration panel |

Intergrative facade panel for exterior wall thermal insulation | |

Interior wall decoration panel | |

Flooring for loft interlayer, container house, light steel villa | |

For subway, tunnel,baseboard, outdoor furniture | |

Roofing sheet | |

Thinner lining board for stone |

Product Specifications:

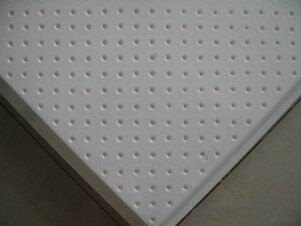

Images:

- Q:What does the glass wire add to the cement?

- In the cement board plus glass fiber to improve the flexural strength of compressive strength, will not be easy to break

- Q:Outdoor use of cement pressure plate can not

- The With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Widely used in civil and industrial buildings. Can be used for building floor, interior wall panels, exterior panels, ceiling panels, curtain wall panels, composite wall panels, insulation materials, roofing and other parts.

- Q:Do the ceiling is good or good with gypsum board good

- 1, gypsum board composition materials Gypsum board as the name suggests is gypsum as the main material, but also joined the fiber, adhesive, modifier, after mixing press, dry from. 2, gypsum board performance Gypsum board with fire, noise, heat, light, high strength, low shrinkage and other characteristics, the general use to the finishes, such as partitions, partitions, ceiling, veneer, etc., but not for wet environments, Sex is poor.

- Q:Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Q:i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

- Q:I am installing a new tub and enclosure. I have exposed everything down to the studs and plumbing. I have heard that when installing backer board in a shower the best material to use nowadays is cement backer board (like Durock) since they are more resistant to mold than green board. Anyways, what is the correct process for installing cement backer board in a shower? Do I just screw the boards right into the studs, or do I have to first put down another thin barrier sheet (like some waterproof material), then the cement backer board, then another waterproof sealant, then I can install the enclosure? I just want to do this right the first time and not leave any steps out of the process. I would hate to develop another moisture leak and then find out that my barrier did not hold up well. Thanks and take care, I appreciate any help.

- I normally install green board to the studs tape the seams and the corners and then install the wonder board over the green board. This gives a float look and a full one inch barrier. it also brings the wonder board out far enough so I can drop over the lip edge. I space the wonder board 1/8 to 1/4 from bottom I silicone seal the bottom edge to the tub/shower pan I silicone seal the outside edge to the wall and the bottom edge to the floor. I run a thin bead from the bottom of both corners maybe 12 inches up. I use proper screws ( rock on ) and plenty of them. then tile I would never use an enclosure as the wear with time and look cheap. the seams are problematic and tend to leak over time and might be the source of your problem good luck

- Q:There is a problem like your team to ask the partition wall have what form in addition to light steel keel gypsum board there are no other

- Factory or office, then you can use Caigang sandwich panels, the family can use colored glass sliding door or do closet to do partition

- Q:some say lay 15 pound paper what gives?

- It's a cushion -bed for the cement board. Less chance of it cracking if cushioned.

- Q:Why does noise do not mean sound absorption? How to use good sound insulation, sound absorption material to handle the hall? Ask the master enlighten me!

- Simply put, the sound is to eliminate the sound outside the room, silence is to eliminate the noise inside the room. Depends on what you need in the end of the hall. Is too noisy outside or room sound is not good.

- Q:Our contractor says green board is required for his corian shower because it is coved and waterproof. Is he right? The City says cement board is a new requirement because mold can get in. However, they will accept the manufacturers recommendation. We want to follow the building code.

- Absolutely, spend $30 more and use cement board. As a builder, I always line the studs with plastic, which overlaps the shower pan, then screw cement board over the plastic overlapping the shower pan (usually PVC product), then use red guard to seal seams and screw holes, then apply thinset mortar for tile, or mastic for corian, then seal all joints with grout sealer. It's your house and your money...stick to your instincts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireproof Fiber Cement Board Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords