CMAX hollow WPC project decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| | | | | | |

| | | | | | |

| | | | | | |

| | |

Packaging & Delivery

| Packaging Detail: | REGULAR EXPORTING PACKAGE |

| Delivery Detail: | 15DAYS |

Specifications

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

STOCK FROM CHILE WAREHOUSE

STOCK FROM DUBAI LOGISTICS CENTER

BID FOR BIG CONSTRUCTION PROJECT

Landscape use wpc

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

6> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

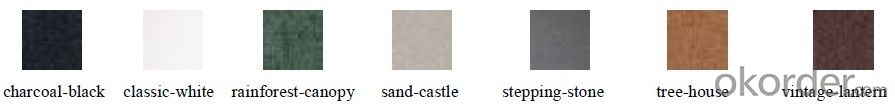

C. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

- Q:pergo flooring 6 yrs old wearing on ends of some panels.

- It isn't clear what you are asking. The placing of the question mark makes it look as if you are asking if the floor has worn out. I haven't heard of laminate flooring wearing out, but it hasn't been in general use all that long. Wearing out says to me that the surface finish has worn through to the substrate. I don't know how the ends could wear out because you don't walk on the ends. If the ends or edges are swelling or lifting, that happens when they are exposed to moisture. The only fix is replacing the planks which are doing that.

- Q:I used to live in an South American country and I moved to Canada. I need to know why aren't there holes on the bathroom floors in Canadian bathrooms? Where is the water supposed to go if I have to clean the floor? Should I just wait for it to evaporate?Also every time a toilet clogs, it leaks downstairs (in every single building I have seen, and at least two of them are very very new). Is this normal? Will it leak also when washing the bathroom floor??

- I live in the US and we don't have holes in our floors. Use a mop and soak up the water.

- Q:Vinyl tile floor

- Do a search for floor wax.

- Q:Saw a floor of the substrate is black, this is not the quality of the floor is also very good brand more

- It should be said that the relationship is not.

- Q:I have an old house and when we pulled up the 3 layers of tiles the concrete is black. This is from the stuff they used way back when to lay tile. In my research I have found all kinds of stuff on how to paint new cement. Can I just paint or stain it after I clean the floor. Or do I have to get all the black stuff off the floor first.

- Jack, I recently remodeled an Office Max Store and we had the same adhesive under the tiles of this old stirp centers flooring. Here's what worked inexpensively: Get some low odor mineral spirits and soak the floor until the adhesive begins to break down and release. Now scrape the glue up and repeat until the floor is clean. I'm going to suggest that you paint this floor with an epoxy or xylene based paint. I recently used an Ace Hardware Xylene Based Concrete Paint, used for wharehouses, garages and airplane hangers that was incredible in respect to coverage and durability. Mike Lonergan TradesProfessional, Inc.

- Q:We are going to install 20mm laminate flooring and I heard that the underlayment is just a sound buffer. We currently have subfloor that is pretty flat and even. Can I omit the underlayment? What are the disadvantage of doing so? The laminate flooring will not have glued on back underlayment either. It will be a floating floor.

- No you do not need any other underlayment. It is a bad idea to double up on padding because this will cause the joints in the floor to flex more and weaken the tongues, causing eventual board separation. It's very important that you use the 6 mil plastic for vapor barrier. Rosin paper is useless over concrete. Overlap the plastic a few inches and tape the seams and you should be fine. Feel free to email any other installation questions

- Q:Do not know how to transfer to the students, World of Warcraft now right point on the floor will automatically go over, I cut the angle when often run errands, it is not convenient, bile book Gu Guai the difference between the dual set of this setting is where the Cancel it more

- Open the interface, click the mouse, click on the move where the hook removed

- Q:I am looking at installing a floating laminate floor in my house and would like any input on which type of flooring would be best since there are so many options. (ex: thickness, brand, COST, ease of installation, underlayment already attached vs laying underlayment, type of wood, etc...) I want the floor to look nice but I don't want to break the bank either. Any help and/or tips from someone who has installlation experience would be greatly appreciated. Thanks in advance

- The big problem with these type of floors is if you get any water on them they are ruined. The edges swell up and curl and look a real mess. I would never use these types of floors because they are so easily destroyed.

- Q:An air freshener of all things leaked on my linoleum floor, and now where it leaked the laminate shine part of the floor is peeling away, exposing the sticky part of the floor underneath. Is there any way to repair this?

- there is not a restoration equipment that i be attentive to of, yet maximum linoleum is vinyl composite based. you would be able to wanna look into the charges on some peel and stick 12 x 12 linoleum tiles, they are relatively low-value as long as you dont have plenty to do. consistent with risk do merely rather further out from the washer and dryer

- Q:im trying to solve 16=floor((100*floor(.15*X))/86), but i dont exactly know how

- The floor function maps a range of numbers into a single function. So there are infinitely many solutions. You could solve it as an inequality. 16=floor((100*floor(.15*X))/86) means 16 <= 100*floor(.15*X))/86 < 17 Rearrange those inequalities to isolate floor(.15*X). Then on each side you'll once again have a range of values for .15*X. Edit: 16*0.86 <= floor(.15*X) < 17*0.86 13.76 <= floor(.15*X) < 14.62 But because floor is an integer, that means that floor(15*X) has to be 14. It's possible I might have gotten a range of integers at this point. floor(.15*X) = 14 14 <= .15*X < 15

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX hollow WPC project decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products