China Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of China Manual Edge Banding Machine

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers.

Advantages of China Manual Edge Banding Machine

1. Easy operation.It can band the straight edge;

2. Feedstock use the frequency transformer to adjust the speed;

3. Having the auxiliary heating to ensure the glue flows smoothly;

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue ;

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle;

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace.

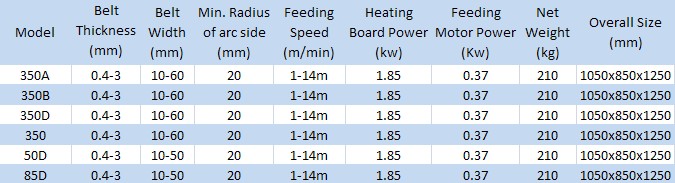

Specifications of China Manual Edge Banding Machine

Package Details

- Q:9 eco plates can edge it?

- Yes, it is a kind of material used to protect, decorate and beautify the furniture, plates and sections. It can make the furniture appear clear and colorful. If the process is good, the problem is not large. But the edge of various plates is different (due to the different thickness of the plate). Where to buy plate, who will be the edge banding?. Remember! Good steel used in the blade, to superior material, buy Decorative Building Materials website, choose some good material, use also save worry and effort.

- Q:Cabinet door panel edge strip off how to do?

- If the door edge degumming not too serious can be used with adhesive, or if the change cabinet door degumming serious.

- Q:How do I seal the edge?

- Edge banding machine!

- Q:With full automatic tracking edge sealing machine, that is, curves and straight lines can be "edge banding" mean?

- No, the copy tracking is to fix the shape of the head and tail of the board, such as the duck's tongue

- Q:Do you have an edge seal for each contract?

- For original truth

- Q:How about the east edge banding machine?

- East edge machine, is not good, we bought a high-speed automatic edge banding machine, only for a year, a lot of small problems, seal and wire plate, plate processing is good and put aside, I am the master factory

- Q:South Hing edge machine before the block after the action no action to repair block

- You first check the sensor after cutting, put the machine up and running, and then press the button on the sensor, the blade is action, there are several general reasons, edge powder coarse trimming knife trimming from flying to the sliding track after the knife, the knife head of the motor after Qi decline or not second see the rise, after running when the knife is exposed to the knife after induction iron above the general contactor will come into contact with the red light, the third one is to look at your level on the sliding seat after the knife barometer is closed, no air supply, and look after the two black knife successive joint pressure pipe if the control valve torsion die, there are usually two control valve, a pressure control after a knife upward, downward pressure control after the knife, I hope to help you

- Q:Full automatic edge banding machine, what price, thank you

- What kind of products would you like to make and what grade would you like?. I am doing wardrobe, edge are basically used in 2-3 mm, is used with pre washing, built 3, spent more than 130 thousand. Qingdao Naisen brand, product line overall full.

- Q:How about the semi-automatic edging machine and the three row drill?,

- The workers are very expensive, my friend asked me to buy, is a manufacturer of Qingdao, named Qingdao Haoda edge machine woodworking machinery, cutting saw and drill, I am still very good quality with

- Q:My semi-automatic edge sealing machine, the edge is not good, how to adjust?

- Look at the temperature. Look at the bite

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

China Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords