Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

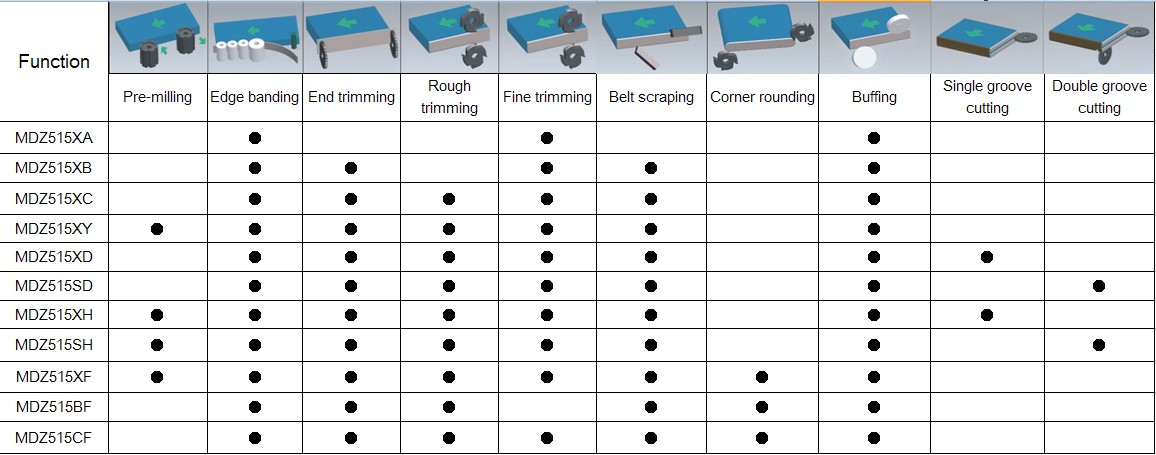

(1) Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

(2) Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

(3)It adopt the imported original electrical machinery, each performance is better.

(4)It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

(5) Blow up and down the side, surface polishing up and down and so on.

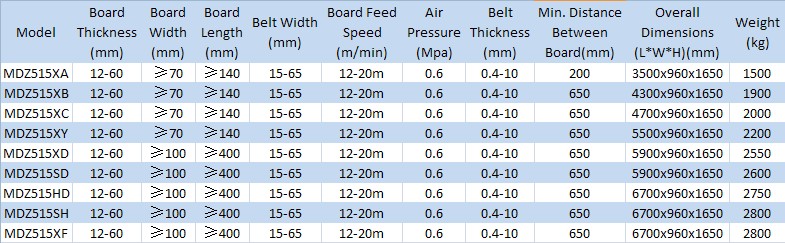

Specification

Advantages

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

Main Functions

- Q:Furniture edge banding machine generally how much?

- Imports: for example, heroic, IELTS, 100 million, etc., more expensive, 20-300.

- Q:Is it easy to use an edge seal? Which one is better than a nail free glue?

- Edge sealing spirit is an aquatic product. The initial adhesive force and weather resistance are different from those of nail free gum.

- Q:Do not paint board do cabinet, glue edge banding what glue?

- If you use hand, you can dispense with glue

- Q:What is woodworking edge banding machine?. What role does it play?

- Including many kinds of woodworking machinery, such as coating machine, laminating machine, sealing machine is one of them, is a kind of woodworking machine can automatically complete the work of the wood plate edge, straight edge and curve shaped edge theory (portable), but generally use the linear edge banding machine. In addition, according to the degree of automation, it is also divided into semi-automatic edge banding machine and automatic edge sealing machine. Wood edge bander main body, processing group and control system, semi automatic and automatic processing of the main difference is that group is not the same, generally only: semi automatic gluing, edge trimming, polishing, up and down; and automatic general: pre milling, gluing, sealing, edge next, rough trimming, refinement, profile tracking, scraping, polishing, slotting. I buckle, the first five, second seven, third fourth three shops, fifth, eight, sixth seven, seventh second, eighth seven, the last six. These two devices are used for furniture such as cabinet doors and other production, but generally small plants, usually with semi automatic is enough, I do not recommend you use automatic, it also saves the cost of the need! Semi automatic more than 20000 to more than 50000 automatic.

- Q:What's the aluminum alloy edge for cabinet door?

- Good, but a long time in the tank door easily, if love is Aluminum Alloy, can put the door body paint (including four) and Aluminum Alloy edge.

- Q:What's the adhesive tape for the desk edge? What glue do you use?

- Structural adhesive, carpentry glue

- Q:The difference with the closing edge?

- So is the diameter decreases; edge edge bluntness.

- Q:I would like to do their own solid wood particle board edge banding. Use hot melt adhesive. But there is no machine. Can I ask if artificial can do? Quality is good?

- I don't think so. What's wrong with it? How do you melt it? How do I press? How flat? A little repair, do not say, do not spend a lot of time to say, the quality is certainly not!

- Q:Do the overall wardrobe, piecework wages can count to how many square meters, blanking, edge banding, drilling, all the procedures should be considered?

- The minimum material should be opened 12 yuan, or else no one to help you do, the next is critical, the master of the process is not in place, the waste of relatively large plate, so good master, the money is also more expensive.As for the edge, about 8 yuanRow hole, 7 yuanTrial assembly: 22-25 yuan / flatInstallation: 32-35 yuan / flatThe total cost will be around 80-90 yuan per square meterThe above is for reference only:

- Q:Can the automatic linear edge banding machine only seal the straight line? How about sealing the curve?

- A curve edge sealing machine is a semi-automatic edge sealing machine. When the belt comes out from the gluing shaft, the belt is pressed on the board by hand. There are also automatic, but the automatic is too slow?

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b)Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords