Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Straight Edge Banding Machine

1). Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2). Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3). It adopt the imported original electrical machinery, each performance is better.

4). It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5). Blow up and down the side, surface polishing up and down and so on.

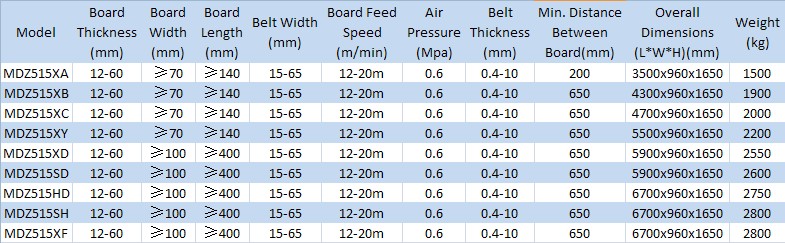

Specification of Automatic Straight Edge Banding Machine

Advantages of Automatic Straight Edge Banding Machine

1). Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2). The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3). End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4). Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5). Profiling unit, to make board end smooth and aesthetic.

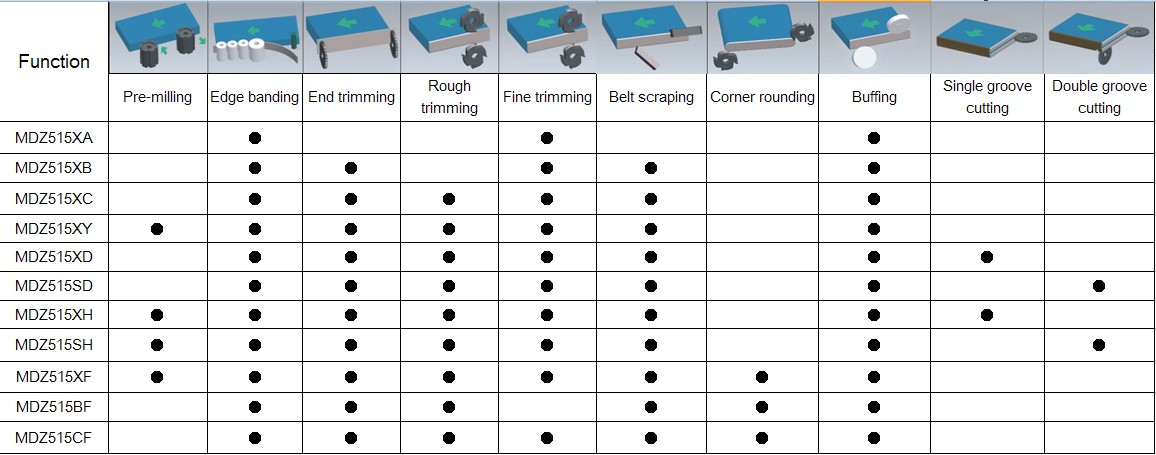

Main Functions of Automatic Straight Edge Banding Machine

Packing of Automatic Straight Edge Banding Machine

- Q:Cross stitch edge ornaments how?

- The embroidered figure leaves two or three, the rest are cut off, and then put two pieces of the same can repair the suture, suture when in fact it is best not to use the fishing line, because it is not just the line Yuntie, with cotton, nice and strong, the color edge of cotton to choose if you stitch, is cluttered with black or white, you try, definitely better than the suture line.

- Q:Do medals, wooden doors, heat transfer, edge banding machine, which sell well? Quality assured? Good after-sales service?

- You can use a device, that is, according to your product shape, if the door and medal shape exactly the same, you can completely use a device,. If not the same, it is necessary to make different knives according to your products, and hot stamping rubber wheel. For further information, call me; 14763909633; Li Jichao. I am Lin Woodworking Equipment Co. Ltd. Please call me again before the next Baidu (stamping edge machine) Lin supply special medal wooden rhinoceros stamping sealing machine. Ha-ha

- Q:Do you have an edge seal for each contract?

- Edge seal chapter for the contract inside the page is not replaced, if the contract is also a small number, each page has a signature, it does not seal the chapter is also ok.

- Q:PVC edge banding process?

- PVC sealing strip is a new plastic product processed by poly ethylene (PVC). It is suitable for sealing edges of furniture and MDF board. PVC sealing edge strip manufacturer, Yimei plastic products! The first is that the granulator granulation, with poly vinyl powder and adding way with certain agents such as calcium carbonate granulation, and then into the extrusion workshop, the plastic products injection mold filling and extrusion, the former is used for food is plastic molding, we usually use plastic boxes and plastic bottles, the latter industrial plastic molding, edge is extruded, as the technology matures, there have been more and more environmental protection, extrusion molding after re entering the printing shop, we see the edge of the wood color and color, is printed, printing after drying can packing.

- Q:How about the semi-automatic edging machine and the three row drill?,

- So-so。 The main service is not good

- Q:Method for using small-sized edge banding machine

- 1. Turn on the power before checking whether the switch is in the closed position. Close the trimming and turn the heating switch on the right to make it work.2, the edge belt is arranged on the rotating disc edge is greater than the thickness of 3-4MM, otherwise edgeband can not completely seal plate, there will be a period of above or below the seams phenomenon, the edge by hand pressure with five-star lever into the scissors seat, front and rear belt pressing lever presses down edgeband not too tight, not too loose, too tight edgeband cannot pass through the pressure rod, loose edge will appear in front of or behind the phenomenon of deviation.3, before the start of the work to see if the melt has been melted, and then send the material size of the pressure modulation plate thickness, size, start the transfer switch, check the amount of sizing, and whether it is suitable for working conditions.

- Q:Manual edge sealing machine price

- You gonna pay? What products are the main products? I also have an aluminum foil bag and that kind of edge sealing machine,

- Q:Why have edgeband glue plate coated with glue. Temperature semi automatic sealing machine 180 yellow transparent glue plate thickness of 2 cm, multilayer board seal good adhesive was cold on a tear off, rubber coated with uniform and thick edge does not have what reason, please play the edge division our guidance, thank you

- In the past our customers also met you this kind of circumstance, in the premise of not exclude you glue quality problems, may have had several problems: 1, the environmental temperature is relatively low, resulting in hot melt glue after the temperature is not enough, not sticky edge band, you can improve the temperature of hot melt machine. 2, sealing machine seal in the window or fan tuyere, will also lead to low temperature, you can remove the window or fan position, or use the board to block the air outlet. I hope to help you, Jincheng plastic industry hot-melt glue edge.

- Q:Do the overall wardrobe, piecework wages can count to how many square meters, blanking, edge banding, drilling, all the procedures should be considered?

- You can use the software to solve Oh, Hongguang wardrobe software you can draw a three-dimensional renderings in about 20 minutes, then according to the actual scheme, can be a key to generate the CAD size map, quotation, material etc..

- Q:Ask everybody a thing, how much is that cloth sealing edge strip one meter?

- Buy material tired ah!

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b)Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords