Cantilever Segment Launching Gantry with High Quality

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

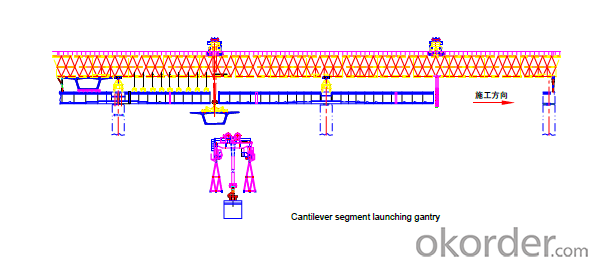

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q:How many special operators do you need to build a bridge machine? What kind of special operations personnel should be held?

- Other construction workers 10~20 ranging. See the specific operation of the type of equipment.

- Q:Main components of bridge erecting machine

- 1, armThe machine arm is bearing girder erecting machine, double box girder structure, according to the stress condition of the machine arm and finite element calculation, each box girder design into cross-section form. The full length 66.0m, the box girder is high 3.0m, is divided into six sections; the center distance of the two main girders is 9m, and the high-strength bolt connection is adopted between the segments. After the disintegration of the segment can be transported by road or rail.

- Q:Bridging machine (i.e. mobile support method to build bridges) what are the advantages and disadvantages of bridging machine

- In general, the bridge girder erection machine is to be prefabricated in the site of the beam to the bridge pier, the advantage is that the quality of the beam body control, erection speed, short construction period, suitable for prefabricated installation method.

- Q:Bridging machine which consists of four parts

- A, power system including diesel engine and related auxiliary equipment;B, transmission system - including torque converter, transmission, front and rear drive axle, rotating shaft;C, walking system - including tires, rims, front and rear frame swing frame;

- Q:Bridge erecting machine belongs to bridge or gantry crane

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down. But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q:How much is a bridging machine

- Bridge erection machine is mainly composed of steel structure, lifting, walking and other components, of which the proportion of steel structure

- Q:How does the bridging machine work?

- If this thing can be explained with the image should be more clear

- Q:I would like to know the working principle of JQ IV 160t/40m bridging machine?

- The guide beam is composed of double girder truss, a connecting pin, a connecting frame, the front rear connecting frame, wire rope fixing rack etc.. The guide beam is arranged on the lower part of the central assembly (including 2 active flat, middle, middle oil shake rolled flat top), tail assembly (including 2 tail oil top and tail legs and tail bearings), front assembly (including 2 sets of active front roller, flat, flat front beam wave temporary support, front). The upper part of the two guide beam is welded with a track, and the track is provided with 2 longitudinal shift flat car assemblies. The guide beam is arranged inside the platform, or via bridging machine can go through temporary support from Taiwan to the top cap.The longitudinal moving flat car assembly is a single track active flat car, each longitudinal shift flat car assembly is controlled by the electric circuit to realize the longitudinal walking. Can be used alone, can also be used online.The moving car is composed of two parts: the walking mechanism and the lifting mechanism. The lifting mechanism is used for hoisting and the traveling mechanism realizes the lateral displacement.

- Q:Safety slogan for bridge erecting machine

- Hello hello!Safety slogan for bridge erecting machine;1, safety first, prevention first!2, scientific development, security development!

- Q:What are the conventional lifting equipment? Bridge erecting machine is a kind of lifting equipment

- The standard is the Dalian crane factory out of a set of plans, covering each tonnage, span height are certain old. Non - standard is the new crane design specifications of the product, the old light a lot more, more powerful, can be based on the design of different tonnage span highly targeted. GB door machine is generally only state-owned factories to use, and now the market may account for seventy or eighty of the non - standard bar,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cantilever Segment Launching Gantry with High Quality

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords