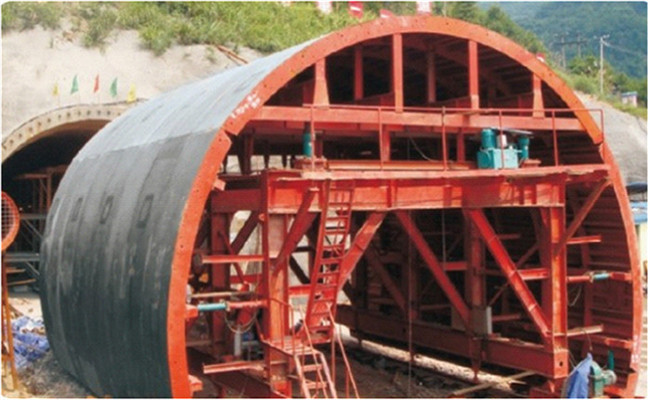

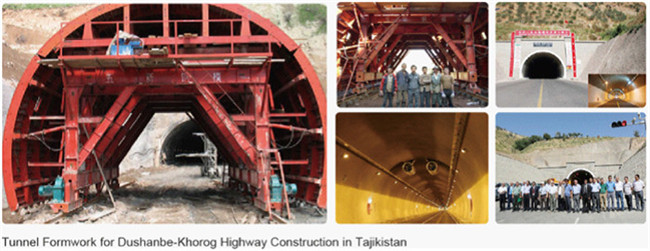

Tunnel Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction & Application:

● Keep suitable formwork strength, make the vault and side wall be smooth in the secondary lining operation.

● Limitedly analysis and calculate the stress to optimize the structure, which can guarantee the strength and stiffness, and also reduce the steel consumption and construction cost.

● Implement standardization renovation, use standard component, promote its versatility and improve repeated utilization factor.

Features:

①Good concrete quality

With full steel materials, high load bearing capacity and stiffness is achieved, that makes perfect concrete surface.

②High-speed of installation and removal of the form

The formwork is fully hydraulic, with hydraulic cylinder to prop & strip, and lock mechanically.

③Easy operation and safety

Projects:

- Q:What is the role of the grid steel frame and steel mesh in the power tunnel

- The production of the grid steel frame component production and installation grid steel frame component is suitable for the production of the steel frame of the initial lining and the support of the digging tunnel. The steel grid with steel and steel by welding is composed of steel frame, steel grille by assembling (bolting, welding) after the formation of the steel arch structure after initial support structure of sprayed concrete, which is applied in soft soil tunnel structure is the most effective measure.

- Q:The tunnel lining is wood, how should support?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q:Demolition of tunnel bearing formwork for several days

- The removal time of concrete wall and beam column pouring template is determined according to the strength of concrete, different situations: different removal time of concrete strength of the bottom die and the bracket removal should meet the following requirements:

- Q:Where is the B-B section of the tunnel invert reinforcement

- Tunnel invert refers to the bottom of the tunnel (anti arch, so called inverted arch)

- Q:The tunnel has the super big pipe shed and the lead small conduit, is carries on the blasting excavation first or carries on the advance support first, has the anchor rod in the tunnel, this between the construction craft order is any

- The excavation of invert waterproof plate, blind pipe and steel bar at the bottom of the tunnel, and the pouring of invert arch

- Q:The arch and the arch of the tunnel

- This part of the tunnel lining is generally the first pouring, pouring formwork trolley can be placed on the inverted arch concrete and support, to the construction of the tunnel arch wall concrete.

- Q:How many meters can be poured in the first floor of the 2 level of the surrounding rock of the railway tunnel?

- 6 excavation methods of tunnel1, full section method2 step method3, three steps of the 7 step excavation method4, septal wall method (CD method)5, the intersection of the next door method (CRD method)6, double side drift method

- Q:What are the reasons for the two lining concrete lining of the tunnel?

- (3) the concrete pump tube, vibration rod and other mechanical repeated impact, workers trample or vibrator touch bar, caused by displacement and deformation of steel exposed.

- Q:I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- Tunnel lining trolley design software is CAD, the use of the software for the design of the structure

- Q:What is the vault vault seal and dead seal please give a detailed drawing of the drawing bar do not know how to do?

- The arch support is an adjustable template or a small template

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tunnel Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords