First-Class Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

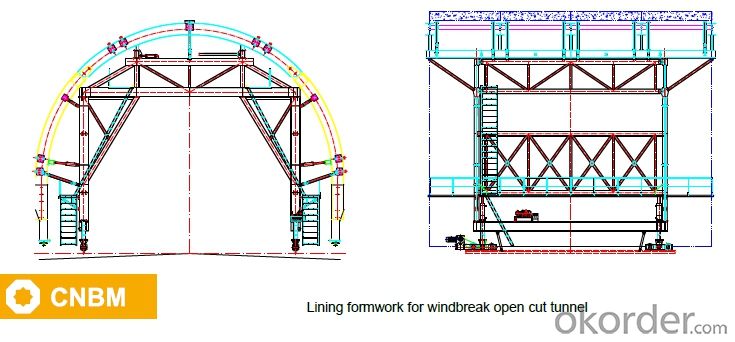

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

Advantage

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q:What is the role of the grid steel frame and steel mesh in the power tunnel

- The production of the grid steel frame component production and installation grid steel frame component is suitable for the production of the steel frame of the initial lining and the support of the digging tunnel. The steel grid with steel and steel by welding is composed of steel frame, steel grille by assembling (bolting, welding) after the formation of the steel arch structure after initial support structure of sprayed concrete, which is applied in soft soil tunnel structure is the most effective measure.

- Q:What is the simple calculation method of the tunnel excavation unit price

- Parameter valuationThe valuation of parameter method is the method of calculating the multiplication coefficient according to a certain cardinal number or the custom formula. This method is simple and clear, but the biggest difficulty is the scientific formula, accuracy is difficult to grasp. This method is mainly applicable to the construction process must occur, but it is difficult to predict the specific items in the bidding, but can not separate the project content of the project measures. If the valuation night construction fees, two handling fee, rain during construction can be used in this method.

- Q:Tunnel two lining car moving outside the template after the demolition of how the car is similar to the nature of the sliding movement and concrete off

- In addition there is a template on the trolley Jack and hydraulic cylinder electric control, can be extended to shrink, when the formwork is to open the template of the trolley, when the contraction of template removal

- Q:Two tunnel lining reinforced concrete template to price behavior can be contracted

- There is two times of lining concrete pouring, the normal price is within 100 yuan, this is the pure artificial price, does not contain steel trolley and various materials two tunnel lining.

- Q:Main diseases and prevention of tunnel

- Tunnel shotcretePhenomenon: the concrete spray layer and the rock surface is not bonded, concrete spray layer between the bond is not good.Cause analysis: the loose rock not clear spray surface; shotcreted rock debris is not scum washing or flushing thoroughly with wind pressure, water pressure; surface by spraying water, water, water concentration of untreated concrete spraying interval; before a layer of spray surface without wind, water washing scum. The air pressure is inconsistent with the spray distance.Preventive measures: remove the loose rock, clear surface by spraying of water, slag floating debris; water, concentrated water point of the surface by spraying with gouge, guide the drainage treatment of buried pipe; sprayed concrete before spray test, to determine the wind and spray distance coordination relationship between.

- Q:When the two lining of the tunnel is used as the lining concrete of the two, how to lay the trolley? Please kindly explain steps.

- The next two large positioning along the side mode, re positioning of two small side mode along the point, then turn to check the center point and elevation, if not the positioning deviation is complete, then re adjust the positioning deviation! If you have time to measure the location of the site can be set up, then you do not nail this method, the five points directly to the elevation and mileage can be controlled for a long time

- Q:I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- According to the design requirements, draw the spare parts drawings, and then workers in accordance with the production drawings!

- Q:I would like to ask the tunnel step method excavation, the height of each step is how to divide?

- On the circular arc heading cutting method, the excavation of each cyclicfootage and steel frame with same interval, after the excavation will be used in the initial support, the excavation behind the steps of 8~10m, after the excavation construction of initial support and invert, and then the middle rock pillar grouting reinforcement. (4) of excavation the surrounding rock and the surrounding rock in deep buried section IV and supporting: IV rock by step excavation method, step up the steps behind 8~10m, up and down the steps of primary support construction must follow with the excavation. Rock class take the whole section excavation method. (5) are the simple types of rock excavation self assembling drilling trolley, with dump truck shipment mucking loader. In order to ensure the safety and stability of tunnel construction in soft rock section, the construction must follow the "weak blasting, little disturbance, short excavation, strong support and frequent measurement, tight lining", in the application of The following measures shall be taken

- Q:12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- Seven hours after the maintenance of formwork, pouring a every day is no problem, that is to say a month to about fifteen die casting.

- Q:What is the concrete construction of the tunnel invert

- The construction of concrete is related to the non - construction concrete

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

First-Class Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords