building tunnel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

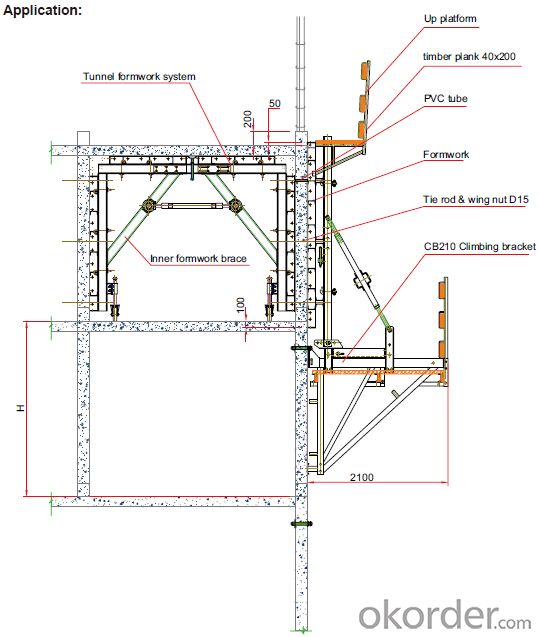

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q:Who can give me detailed tunnel construction process

- On the inner side wall heading section is advanced, the footage was 0.7m immediately on the rock surface at the beginning of the spray, install the first layer of rock along Phi 8 steel mesh, and connected into a whole, set up active and temporary supporting steel arch, and the arch and a connected whole Phi 25 steel, drilling into the phi 25 hollow bolt and grouting, the installation of second layer steel mesh shotcrete layer to design contour line, pay attention to every compact trusses on the back of the footage, about 5~10m after the excavation under the heading section, and the lateral wall of drift can also present a ring section excavation footage was about 20 ~ 35m, support the arch excavation core soil upper arc heading, 3 ~ 5 after excavation footage and central support, under the section of tunnel bottom and the lower end of the previous about heading completely combined with closed loop, is divided into seven excavation, all operations must strictly follow the open Step by step, must be two inside the wall first, follow up the process step by step process. At the same time there must be monitoring data as the basis, redistribution of stress or conversion, will increase the support displacement, and strata subsidence and deformation, should strengthen the monitoring capacity before and after removal of the tunnel deformation and supporting force measurement,

- Q:In the tunnel construction, the water stop belt and the water stop strip are respectively used in what place, the construction joint and the subsidence seam many meters set a, above all has any function

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and fixed template (Figure 2), such as perforation, can only choose the installation area on the strip edge, not to damage other parts

- Q:Ask, general highway tunnel measurement with the total station to measure which aspects? The more detailed the better

- Steel arch support and Lifang line checking, bottom excavation and invert excavation, lining template checking and lofting, invert pavement template checking, reinforced lofting and lining ditch school inspection, line and template checking

- Q:Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- Course (bed) refers to the structural layer below the base level. Its main function is to separate water, drainage, antifreeze in order to improve the working conditions of the base and foundation, and its water stability requirements.

- Q:How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q:The tunnel has the super big pipe shed and the lead small conduit, is carries on the blasting excavation first or carries on the advance support first, has the anchor rod in the tunnel, this between the construction craft order is any

- Measuring and setting out the drill hole charge blasting, ventilation, smoke exhaust, water spraying and dust removing, the top of the vertical arch, the anchor rod and the reinforcing steel net, the spraying concrete operation enters the next cycle, and the first branch is stabilized and then the two lining is applied

- Q:The arch and the arch of the tunnel

- This part of the tunnel lining is generally the first pouring, pouring formwork trolley can be placed on the inverted arch concrete and support, to the construction of the tunnel arch wall concrete.

- Q:I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- You are talking about the design of the tunnel two lining car software.

- Q:12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- If the reinforcement in advance or tied to the design of no reinforcement, the normal situation down the car, plus the plug plate, pouring concrete

- Q:How to fill in the tunnel template

- The template is firm and smooth, there is no error, such as leakage

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

building tunnel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords