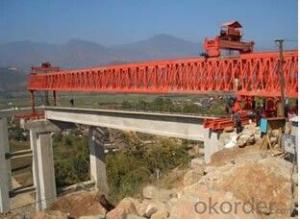

Launching Gantry / Beam Launcher

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This machine can combine 900 ton tyre trolley to work for double-line high speed Railway Bridge with box beams in the length of 20m, 24m and 32m. |

- Q:How many special operators do you need to build a bridge machine? What kind of special operations personnel should be held?

- General bridge machine, the need for a total command, operator 2, mechanical, electrical, hydraulic engineer

- Q:Such as Title ah.....I am sorry that the steel structure

- 84261120 bridging machine84261120 highway bridge erecting machine84269900 highway bridge erecting machine84798990 bridging machine

- Q:The difference between the bridge erecting machine and machine

- Bridging machine and bridging machine are actually similar.

- Q:Bridge erecting machine belongs to portal or bridge crane

- The bridge is generally used for loading and unloading containers, and the door is generally used in the container crane.Bridging machine and the above 2 are not the same.

- Q:What should be done before the erection of the bridge girder

- But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift.

- Q:When is the installation period, which brand is reliableProfessional name should be crane safety monitoring and management system

- Safety monitor of RJ-180 type bridge machine by a dynamic display of the host (built-in brake control), angle sensor, height sensor, angle sensor, speed sensor, weight sensor, sensor, lateral longitudinal stroke stroke sensor, level sensor, wireless communication module, real-time acquisition and display the running state of the bridging machine.

- Q:Bridge machine has a sale of the code, used to query the bridge machine related information, is generally how much

- 0086 is the number, arrangement of crane factory sales department the orders of the factory will be mostly single beam double beam gantry crane bridge machine factory production of all types of single beam arranged together another individual plant and some other arrangement of course arrangement of rn: LD16T-22.5M 10120188rn 10120188 number meaning 16T 22.5M span single beam is a contract signed in December 2010 0188. Is the crane factory sales order arrangement number

- Q:How long will it take to set up the 30 - meter girder erecting machine on the highway

- Erection of 30 m girder bridge machine total length of 56-58 meters

- Q:I would like to ask what types of bridge machine

- In addition, there is a large project is used, such as the Hangzhou Bay Bridge (1800 tons), Su Tong Bridge (how many tons I do not remember.) Such as the use of highway bridge crane tonnage is very large, where the bridge assembly is generally segmental assembly, there is little in the form of a whole hole.So, you ask what kind of bridge machine model, it is difficult to say, because the product itself is a non-standard product, each manufacturer can have their own unique way to distinguish the name.

- Q:When does the bridge machine not belong to the gantry crane?

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Launching Gantry / Beam Launcher

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords