Whole Span Segment Launching Gantry with High Quality

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

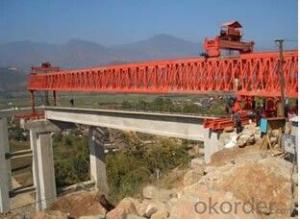

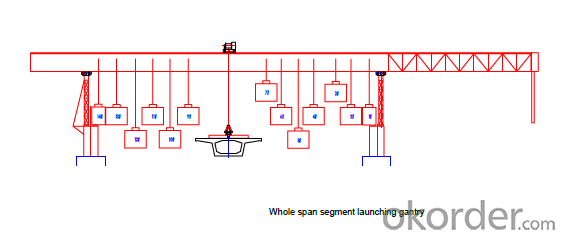

Whole span segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q:Bridging machine (i.e. mobile support method to build bridges) what are the advantages and disadvantages of bridging machine

- Bridging machine is to use a mobile bracket, all work is done in the mobile bracket, face small, quite a long time.

- Q:When the bridge frame is equipped with T beam, there are power lines above, we do not have the height of the bridge, so I do not know whether the power line to be removed.

- The problem is not clear, which and where clearance

- Q:Bridging machine which consists of four parts

- D, brake system - including parking brake, working brake;E, steering system - including the upper and lower hinge body, steering cylinder and the corresponding operating mechanism;F, the work system - including the bucket, the big arm, the rocker arm, the connecting rod and the correlation pin shaft;G, hydraulic system, including hydraulic system, hydraulic system, hydraulic system, hydraulic system, hydraulic system, hydraulic system, cooling system, lubrication system;

- Q:Above the highway bridge construction machine, in the case of the erection of the protective scaffolding, bridge construction can be opened to traffic

- Protective scaffolding can only be up to prevent falling objects, if the bridge girder or beam body overturned, this protection is useless

- Q:Bridging machine inspection which information and what departments to go? Ah!!!!!!

- The manufacturer will be able to ship the goods at the port of shipment. After the goods have been delivered to the port of export, they must also report to the port entry exit inspection and Quarantine Bureau

- Q:The difference between double guide beam bridge machine and single beam bridge machine

- Single beam bridge machine:The single girder bridge girder erecting machine adopts a single bearing beam, and the bridge erecting machine is composed of a single main beam, a supporting leg, a hanging beam trolley, a moving mechanism, a transverse moving mechanism and an electric control system. Main girder structure generally adopts box type structure of light weight, high stability of the beam, the guide beam can be moved up and down, back and forth, transverse, achieve a heavily beam beam falling in place, continuous erection line, line, curve and other different types of bridges.

- Q:Self-propelled bridge erecting machineMore than 80 tons of self erecting machine price is about how muchKnow the trouble to provide point information!

- Vertical and horizontal electric bridge operation, high efficiency, centralized control, simple operation, convenient transportation and other field weight reduction, 30? 0%, the equipment utilization coefficient, l, skew bridge can be erected at any angle, the radius of curved bridge erection > =250 meters, and only 3 days, the working efficiency can be increased by more than 50% of the machine. Now in the highway on the application, the effect is good.

- Q:What is the technical parameter of 30m/100t fixed guide beam of bridge erector?

- Project WJQ50/180~200 WJQ40/150~160 WJQ30/100~120Maximum lifting weight (T) 180150100Adaptive bridge span (m) 35~50 30~40 20~30

- Q:When does the bridge machine not belong to the gantry crane?

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

- Q:How to weld the wet joint of bridge erecting machine

- Specifically how much I do not know, but the specification can be found

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Whole Span Segment Launching Gantry with High Quality

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords