Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

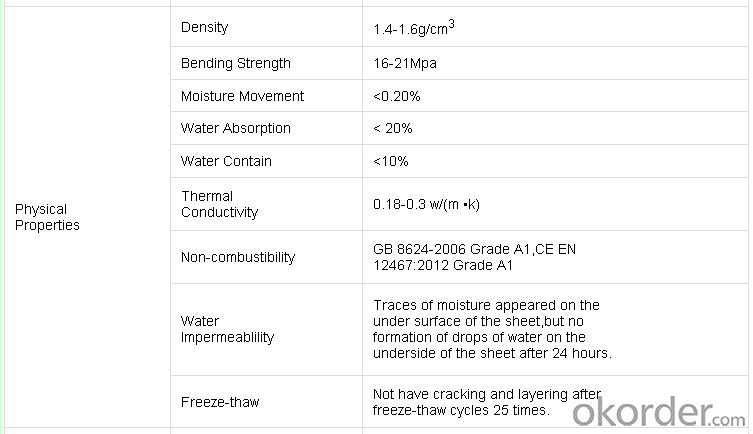

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q:Bathroom with cement board hanging the top, now open the hole to install the lights, so hard to open Oh ,,, which big god to help me out of ideas? Thank you!

- 1, first clean the bathroom floor, in the sewer around the corridor around a clean, 2, buy high-molecular quartz sand beauty mud (waterproof type comes with a bag of 40 or so), please muddy wet floor and then approved flat. Sprinkle water 2 to 3 times before completely dry, although the glue does not dry like cement quickly, sprinkling is also necessary.

- Q:hi, this is my question:To prevent a cement mixer sinking into soft ground, the mixer is placed on a large flat board. Why does this prevent the mixer sinking?the answer will be one of these, which one is it?A The large area decreases the pressure on the ground.B The large area increases the pressure on the ground.C The large area decreases the weight on the ground. D The large area increases the weight on the ground.

- the flat board distributes the weight over a larger area, so the pressure per square inch is reduced.

- Q:Miyan cement board and wood fiber cement board with the advantages of ordinary cement board

- Wooden cement board, the United States rock cement board with high fire performance, FOREX Meiyan cement board to meet the national fire safety standards A level, you can reach two hours of fire resistance, are flame retardant materials; and VIVA wood cement board Because it contains mineralized wood chips, it is possible to meet the B-level requirements of the national fire safety standards.

- Q:Then I have to install marble in replace of this tile. I have laid a lot of ceramic tile but I being told that marble is a real pain in the but. I just started my business and this will be my first big job. Please give me your input. I live in Denver Colorado. Thank you

- Ok, since this is your first big job, you'll want to do it right. Remember that word-of-mouth advertising is the best and cheapest advertising. Yes, the tile should be removed. You won't know what condition the backerboard is in until you remove the tile and if it is in bad condition it should be removed and replaced too. If it just needs a little patching, that could be done with thinset mortar. Marble can be installed just like tile with approximately a 1/4 grout joint. The reason you've been told that it can be a pain is that many people want a very tight grout joint and that is very difficult unless the underlayment is perfectly flat. Also, if the marble is a light color, white thinset should be used or the grey might reflect through the marble. Marble also stains, so a natural, non staining grout color such as white, off white, pale tan or pale natural grey should be used. Marble requires a lot of maintenance if it is a polished marble, so your client should know that in advance. If the marble isn't a high-gloss, sealing might be required too. Good luck in your new business!

- Q:Treatment Method of Cracking of Cement Pressing Slab

- 1, seams before check: 1.1 Check the slit part of the screw to sink into the board surface 0. 5mm, the screw from the board edge 12 ^ -15mm, can not damage the edge of the board, the board should not have significant difference between high and low, if necessary, should be repaired, and then start seam construction The 1.2 must be checked to ensure that the plate and keel combination of dense, seamless. 1. 3 before the seam must be used to scrape the screw around the screw to clean, and then use the wet brush to clean the dust at the slit. 1.4 Check the material, no metamorphic agglomeration phenomenon, meet the requirements.

- Q:Is it a decoration material? What's the difference?

- Wood wire cement board VIVA wood cement board and Smile wood cement board, a specification is 1220x2440, one is 1200x2400, in terms of material are the same, but the surface treatment is not the same, a strong degree of wear resistance, a resistance Grinding degree slightly worse, the thickness of 8.10.12.16.20.24, the United States rock cement board FOREX Meiyan cement board and diamond american cement board, a specification is 1220x2440, one is 1200x2400, the thickness of 6.8.10, the current China is generally 6 and 8, 10 very few.

- Q:How to choose their own materials made of steel structure compartment?

- Each have their own advantages, steel structure loft for its construction fast, safe and stable, high strength, widely used in villas, duplex buildings, the need for buildings on the air. Compared with concrete and wood, the yield strength of steel is much higher than that of concrete and wood. Under the same bearing capacity, the steel structure has a small cross section, which is easy to transport and install. Which are conducive to the production structure within the building, but also greatly reduce the structure due to their own impact on the body itself. At the same time steel structure is simple, short construction period, no maintenance. Late decoration is simple. These advantages are conducive to the transformation of the building structure and reinforcement.

- Q:I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my jumping around on it.

- The blocks themselves are designed to carry a deadload from top to bottom. The walls of your blocks are to thin to carry any outward pressure, like you bouncing on it. I wouldn't trust cinder blocks to hold wall anchors. If you try to hammer-drill the middle of a cinder block, it will shatter. Anchor your boards vertically to the wall so that the floor is carrying any downward force. It would be best to install a deadman board to the ceiling joists which would hold your vertical boards tight to the wall. Anchors in the mortar joints would assist to carry the load more than anything else. Big fat toggle bolts would suffice in the application I described here. Edit, Use expansion bolts, or PL400 construction adhesive with concrete nails to secure wood to the floor. It also occours to me, you could just frame up a stud wall in front of the block wall. Anchor it to the floor with glue and nails, or expansion bolts, and nail it to the ceiling joists up top.

- Q:How to do the effect of water

- Water effect, is a rustic architectural style, the current application is also very common in the country. From Japan's Ando master.

- Q:I have Hardibacker cement board down for ten years. Just removed the ceramic tile and mortar from it for a new tile job. Do I need to retape the joints or should they be stable at this point. The cement board was screwed into postion.

- its a waste of time to tape the joints. once the substrate is combed with cement its bonded together taped or not.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords