Reinforced Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1. Excellent fire-proof performance

2. Excellent damp-proof performance .

3. Durability and long service life

4. CE

With quartz sand ,cement reinforce fiber as main raw mateirals ,cement board is a light board material made throught high temperature and high pressure maintenance , and special treatment .

Major Usage : Internal and external wall materials

Product Advantages:

1. Excellent fire-proof performance

2. Excellent damp-proof performance .

3. Durability and long service life

4. High strength

5. Good heat and sound insulation

Main Product Features:

1. 1220*2440*4-20mm

2. 1200*2400*4-20mm

3. 1220*3050*5-18mm

4. 1220*3660*5-18mm

Other sizes are selectable

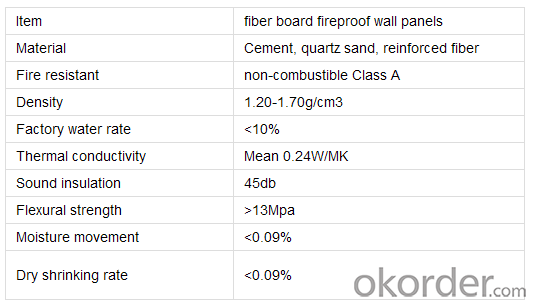

Product Specifications:

Images:

- Q:FC fiber cement plate can be affixed to the aluminum plate?

- Our kitchen and toilet partition ah, closet ah, the ceiling ah, the floor, ah and many other aspects can be used fiber cement board, so now as long as there is a building where you can use fiber cement pressure plate, and fiber cement board is now in the market On the night market uneven, only the choice of high-density fiber cement board is the most reliable, most competitive materials.

- Q:As an artist, I'm experimenting with plaster and cement.As a resident of a temperate zone, I'm wondering about temperature, curing times, and bonding to substrate.I'm working on square pieces of particle board. I rough up the surface with a wire brush to improve bonding to the substrate.Both plaster and cement create heat as they solidify. Are either impaired by a low (and possibly sub-freezing) temperature? I have a makeshift oven that can reach 110 to 120 degrees (F) regardless of the outside temperature. Will heating cement or plaster to this extent improve its ability to bond to wood? Might it only reduce setting time?

- hi we in the building industry use pva glue to coat surfaces for plaster plus adding it to the mix , if you are using finnish coat because of its smooth finnish , if you use a coating plaster it would adhere better but still use pva, cement is different, still use pva but it also crazes if used neat but suggest you use silver sand in the mix it is the smoothest sand and is used by artists in there work it is very fine grained, curing times will be shortened by heat but to much will crack or craze so better to heat a cupboard and store in there and not cook them, hth.

- Q:why does concrete block crumble but driveways and sidewalk do not?I don't have a driveway so basically i want to build a flat portable surface, made out of cement that my jack-stand (for my car) can stand on so the jack-stand wont have to be put directly in the grass.I would need it for the time that i need to take the tires off. any suggestion?

- a piece of a plank or any thick wood

- Q:Fiber cement board and glass magnesium board how to distinguish

- Ingredients: glass magnesium board for the magnesium oxide, magnesium chloride chemical reaction products, is one. Cement fiberboard is a cement, yellow sand aggregate, is a physical reaction.

- Q:How to choose the external wall of fiber composite insulation board fire isolation zone

- Jinkma metal exterior insulation decorative plate consists of three parts, the surface layer of galvanized steel plate (high quality aluminum alloy plate), the surface selection of high weather special coating, the special coating process, according to the need to paint the surface of different colors, and then The special metal embossing equipment rolled into different patterns, and after repeated painting, the formation of a variety of color relief three-dimensional pattern. Can meet the architectural shape and color appearance requirements, to achieve a certain artistic effect. The middle layer is made of flame retardant stainless high density polyurethane foam.

- Q:What is the exterior wall of a light steel structure house?

- Exterior wall paint in accordance with the decorative texture is divided into four categories: 1, thin-walled exterior paint: delicate texture, materials than the province, can also be used for interior decoration, including flat paint, sand-like, mica-like paint. 2, layer pattern paint: pattern was concave and convex, full of three-dimensional sense. 3, color sand paint: with stained quartz sand, porcelain mica powder as the main raw material, color novel, crystal brilliant. 4, thick paint: can be sprayed, can be coated, can roll, can be made of hair, but also to make a different texture pattern.

- Q:I have laid ed cement board down but I did not stagnate the boards.Will this affect the ceramic tile.?

- What do you mean, Stagnate? That means that they would get old or soggy. Do you mean stagger?

- Q:do i need mortar under the cement board?

- No.Do not put any mortar under the board.And do not tape the joints just use straight mortar.I suggest Quick set or commonly known as hot mud.Then use liquid nail to put tile down.then use a mixture of silicone and spray paint [any color] and mix well before applying.Apply with a paint brush and then sponge off every couple of minutes so that none dries on the tile.

- Q:also how much is luber per board foot cost.

- One bag of Cement is 195 pesos. ($4). Cocoa Lumber is P50 per board foot.

- Q:Thanks Alex. How much you think I should charge to install each 4x8 sheet of cement board?

- I used to charge 2.50$ a s/f to install board or prep an area. That would include the board , thin set and nails ( or screws)to do it properly. 4x8 cement board is hard to find and heavier the all HE!!, so hire a friend. 3x5 sheets are much easier to handle by yourself. Any questions you can e mail me through my avatar. GL

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Reinforced Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords