Durable Fiber Cement Board Exterior Wall Siding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

1) fiber cement board

2) Non-pollution: 100% non-asbestos,

3)waterproof, soundproof, insect-proof

2015* durable fiber cement board exterior wall siding

Description

Calcium Silicate Board /fiber cement board

Non-asbestos Calcium Silicate Board----Raw materials are Portland cement, high-purity quartz powder, minerals (mica and perlite etc), and a variety of additives. It is light weight energy-saving building plate with non-asbestos fiber that treated by high-temperature and high-pressure steaming process according to the KTN300 technological standards. It is no asbestos, proved by State Building Material Testing and Inspection Center according to the Standards of Non-asbestos Building Products.

2,Main Features of the (Cement Boards)

Property:

ISO 9001; CQGC; CNAS

waterproof, soundproof, insect-proof

Non-pollution: 100% non-asbestos, no VOC gas, and no radiation.

Fireproof: Incombustibility Grade A; complying with BS 476 Part4\ Part6\ Part7; releasing no toxic gas; zero smoke coefficient.

Economical: Light weight but high strength, save construction costs.

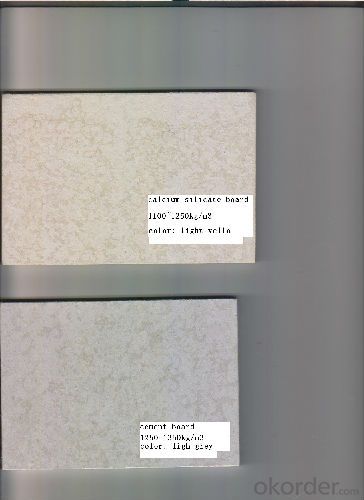

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

5,FAQ of (Cement Boards)

Application:

Main application: partition wall and ceiling

Fireproof structure: fireproof wall, fireproof door and fireproof furniture.

Heat insulation structure: internal heat insulation layer and heat insulation of outer wall.

Sound insulation structure: cinema, meeting hall, music hall, etc, for example.

Wet areas: basement, toilet, kitchen as well as other environment of low temperature and corrosion.

Backing-up structure: best used as filling plate of screen wall. We have developed supporting system of backing-up plate for renowned units of screen wall construction.

Other purposes: applied to furniture, movable floorboard, and office dividing wall.

Specification:

Density: 1.1-1.25g/cm3

2440×1220×6 -25mm

Non combustibility: Class- A (A1)

- Q:I'm my history day exhibit board, and I used rubber cement, but the rubber cement stained the background paper I am using. Now, I have to move things around and organize my exhibit, and the stains are showing! How can I get them to go away??? Help!

- sorry there is no way at all.

- Q:Then I have to install marble in replace of this tile. I have laid a lot of ceramic tile but I being told that marble is a real pain in the but. I just started my business and this will be my first big job. Please give me your input. I live in Denver Colorado. Thank you

- Ok, since this is your first big job, you'll want to do it right. Remember that word-of-mouth advertising is the best and cheapest advertising. Yes, the tile should be removed. You won't know what condition the backerboard is in until you remove the tile and if it is in bad condition it should be removed and replaced too. If it just needs a little patching, that could be done with thinset mortar. Marble can be installed just like tile with approximately a 1/4 grout joint. The reason you've been told that it can be a pain is that many people want a very tight grout joint and that is very difficult unless the underlayment is perfectly flat. Also, if the marble is a light color, white thinset should be used or the grey might reflect through the marble. Marble also stains, so a natural, non staining grout color such as white, off white, pale tan or pale natural grey should be used. Marble requires a lot of maintenance if it is a polished marble, so your client should know that in advance. If the marble isn't a high-gloss, sealing might be required too. Good luck in your new business!

- Q:Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- In accordance with national standards: cast-in-place cement board bearing capacity is 250 kg / square meter, prefabricated board is 200 kg / square meter.

- Q:our cement board was left out in a rain storm and then was installed under marble tiles. will this be an issue?

- Yes it can, but makes sure its dry before it gets closed off (tiled over)

- Q:I had to make some necessary repairs behind the wonderboard and I ended up making 6x6 inches holes through the cement board. I have repair sheetrock in the past but this cement board looks difficult to repair. I have googled online on how to do the repairs but I could not find much. Thank you in advance for all who will answer.

- Patching Cement Board

- Q:do i need to put cementious backer board behind a fiberglass surround shower unit?

- no,,not if its a full surround,,,use green board sheet rock around the edges though

- Q:Do you need to finish a cement board for a shower like you would if it were drywall?

- You should have tar paper between the cement board and the studs to keep the water from the framing since as no one else mentioned, CEMENT IS NOT WATER PROOF. It is not even water resistant, ask anyone with a basement and poor drainage. The water from the shower will not damage the cement board, but it will get through it and affect the wood unless there is tar paper or some other moisture barrier. When you install the tile onto the board you only need to spread the mortar on the same way you would if you used a traditional scratch coat instead of the board.

- Q:I have a small bathroom approximately 4'x8' and I laid down and screwed in cement backer board. However, in my attention to detail I neglected to put down thin-set mortar underneath prior to screwing and taping down the board. I tried to pull the cement board up but I cant get under the tape that I mortared down to get to the screws. Am I in trouble here or can I go ahead and skip that and continue to tile? Please help...

- OK... You didn't specify whether you're doing a floor tile job or a wall tile job. If doing a floor tile job, here is the procedure: You can (but don't have to) apply thin set directly to the plywood and then lay and screw down the cement backer board onto the wet thinset. If your floors are pretty firm already, you don't even need to put the thin set on the plywood. Just screw the cement backer board onto the plywood. The thinset makers tell you to put thinset between the plywood and the backer board just to sell more product. It's an unnecessary step if your floors are already pretty stiff. Make sure you screw the backer board down and hit the floor joists underneath with the screws. Screws only going into the plywood is not sufficient. All screws must enter the joists, so get those marked before you start. Use thinset with a notched trowel on top of the backer board to lay the tile into.

- Q:i am using cement board to cover a wood floor before laying tile. the last time i used it, i cut it with a circular saw (what a mess) dust everywhere. is there a better way??

- Not that I know of. hate the stuff. It works well though. I had to use a skilsaw and score it then jump up and down on the discard piece til it broke. A real pain in the butt.

- Q:Do you know that light through the cement? What is the material and how to do it?

- Litracon PXL as a new generation of Litracon products, with the characteristics of transparent plastic materials instead of the original fiber composition, so that the production of the product possible, but also greatly reduce the cost. Ordered array of light through the lattice to make its brightness and clarity as the display pixel is clearly visible. Through the Litracon PXL technology can not only produce cement board, but also can create a lot of other three-dimensional modeling. In addition, Litracon PXL technology can even be used to produce urban sculpture, street landscape and other municipal landscaping works.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Durable Fiber Cement Board Exterior Wall Siding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords