Building Tunnel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

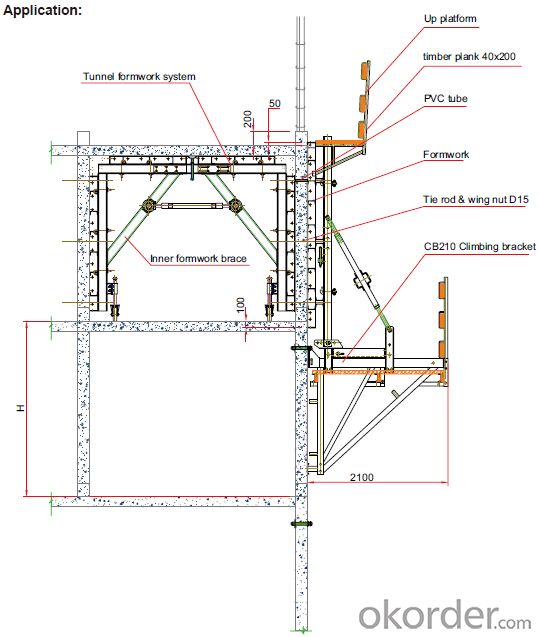

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q:What is the role of the grid steel frame and steel mesh in the power tunnel

- Advanced small pipe grouting small catheter with a diameter of 32-50mm steel pipe, the pipe tip and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q:What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- Summary of construction of the first two tunnel lining

- Q:The tunnel lining is wood, how should support?

- Two concrete tunnel lining, template is used according to the size and shape of the tunnel design custom-made, I-beam welded frame, welded steel plate, known as the "two trolley liner" (hydraulic jack lifting and installation of steel wheel moving on the rail), is generally the length of 9~12m, concrete pouring pump concrete.

- Q:Tunnel construction procedure A cycle of steps

- The construction and tunnel portalWith the support from top to bottom layered excavation hole slopes, and Myeong Dong, and permanent and temporary outside waterproof and drainage should be first, make the surface smooth water, avoid surface water erosion on slope. Is necessary to take artificial slope repair, prevent overbreak, reduce disturbance to the adjacent area; excavation slope will be used in the design of the door, reducing exposure to rock weathering, support to follow, within the jurisdiction for high slopes, if not timely, can not guarantee the safety, and many of the human condition waste,The lining must check and recheck side wall foundation Myeongdong geologic condition and the bearing capacity of the foundation, to meet the design requirements, measurement lofting, frame formwork support, assembling reinforcement, inside and outside the template, the first wall arch integral casting lining concrete, mixing pump into the mold, insert type vibrator with attached type vibrator tamping compaction device.For the construction of portal portal with cut bamboo, also for cutting bamboo cut, plane mounted wooden formwork according to the slope, the slope angle and side end die die fixed into a whole.The waterproof layer and backfillingAfter the completion of open cut tunnel lining strength up to 50% can be removed outside the mold, with a waterproof layer, each layer of backfill should be symmetrical on both sides of the height difference is not greater than 30cm, not more than 50cm, after re stratified backfill to the vault, filled to the completion of a good surface aquifuge.

- Q:Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- The thickness of the cushion should not be less than 70mm, and the concrete strength grade should not be less than C10;

- Q:How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q:Where is the B-B section of the tunnel invert reinforcement

- This part of the tunnel lining is generally the first pouring, pouring formwork trolley can be placed on the inverted arch concrete and support, to the construction of the tunnel arch wall concrete.

- Q:A detailed method is introduced

- The construction methods and technical measures2.1 construction processTo measure the slope, slope protection, Boulder rolling, processing or drainage construction, earthwork excavation, slope protection, inverted arch and side wall foundation construction, liming cave mould, steel banding, liming mould, pouring concrete, concrete outside the health to release, waterproof layer construction, backfilling and protection engineering construction.2.2 construction methods1) Myongdong and a complete portal excavation, excavation with full width transverse dredging method once formed, the first slopes, put the line before the excavation, then drain.2) with earthwork excavating, the small rock blasting method, drill hole, millisecond electric detonator, mucking loaders, dump truck transport, blasting near the slopes, with smooth blasting, in order to ensure the stability of slope. Excavation from top to bottom, side of the construction side slope excavation and slope into the face of the protection works.3) the first tunnel excavation after 10 ~ 20m, and then open cut tunnel lining. When construction, pay attention to Myeongdong and at the joint of the dark hole, from the inside out.4, before entering the cave, complete all slope reinforcement and protection measures.

- Q:How to design the general layout of the tunnel construction organization design

- The location and sketch map of explosive storehouse, spoil yard, office location, living area, entertainment area, temporary drainage ditch.

- Q:How to fill in the tunnel template

- Plane position and elevation meet the design requirements

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Tunnel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords