Bridge Tunnel Formwork System for Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. CMAX Bridge Tunnel Formwork System Description

CMAX Bridge Tunnel Formwork System is designed to reduce material quantity. A compositional steel formwork system mainly used in the building which has regular structure without beams, the excellent formwork system can make the integral pouring for the wall & slab easily achieved.

2. Main Features of Bridge Tunnel Formwork System

- No assembling, easy operation with formed formwork.

- High stiffness, make perfect shape for concrete.

- Repeatedly turnover is available.

- Widely applied range, such as building, bridge, tunnel, etc.

- We can special design according to any requirements.

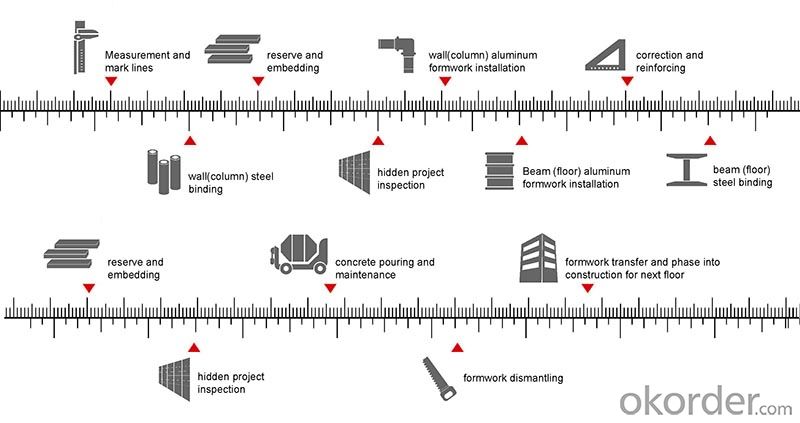

3. Construction Process

4.CMAX Bridge Tunnel Formwork Projects

5. FAQ of CMAX Bridge Tunnel Formwork System

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- It is best to use the high turnover times, can also be used as the use of the beam die, more cost-effective

- Q:How to put the positioning point is based on what is mainly based on my novice, do not

- The first measurement group with total station will be five points (template center, 2 large side mode along the point, 2 small side mode along the projection point) in lofting invert, with nails into the inverted arch concrete as a symbol, and note the nail surface elevation

- Q:1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- When the light into the human eye increases, the pupil contraction, when the surrounding environment becomes dark; into the human eye when the light is reduced, the pupil increases.

- Q:When the two lining of the tunnel is used as the lining concrete of the two, how to lay the trolley? Please kindly explain steps.

- The next two large positioning along the side mode, re positioning of two small side mode along the point, then turn to check the center point and elevation, if not the positioning deviation is complete, then re adjust the positioning deviation! If you have time to measure the location of the site can be set up, then you do not nail this method, the five points directly to the elevation and mileage can be controlled for a long time

- Q:Demolition of tunnel bearing formwork for several days

- The average temperature of 20 degrees, can be removed for 28 days. High temperature removal time is short, low temperature stripping time longer.

- Q:What are the steps? If you build a template, how to fill in the concrete. The tunnel is to dig all the generalist pouring, or digging into the side. Simply say. Better picture. In addition, we have seen a video, the shield machine to dig up the tunnel after the installation of a number of prefabricated panels, but these prefabricated plate is curved. Do not have to fill in a semicircle tunnel?

- Tunnel concrete is completed by the way of edge excavation and lining. After the excavation, the shotcrete is used as the initial support, and then the reinforcing steel mesh is set up. Only after the two lining.

- Q:I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- According to the design requirements, draw the spare parts drawings, and then workers in accordance with the production drawings!

- Q:In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Tunnel two lining concrete pouring mould! Template trolley!

- Q:What is the concrete construction of the tunnel invert

- The construction of concrete is related to the non - construction concrete

- Q:I would like to know the safety awareness of the tunnel lining formwork trolley Prawns to help answer oh

- No special requirements, not special equipmentFirst of all, it must be the track, the sleeper to the sleeper rail

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bridge Tunnel Formwork System for Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords