Assembled prefabricated branch cable FZ-YJV-3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

I. Characteristics of the cables

1. Using factory prefabrication methods can substantially reduce the site construction labor intensity and shorten the construction laying time;

2. Use of cables can guarantee great length and bending property, and greatly facilitates the construction in a complex place;

3. Use of cables reduces the laying space, and cables can be installed together with gas and hydraulic gas pipelines;

4. Their reliability and reliability can be fully guaranteed, for the cables are manufactured in the factory,

5. Sub-branch parts should use high strength sealed joints, which are waterproof and have properties of moisture protection, long-term maintenance and free for repair;

6. Because the cables are directly connected with households with no need of maintenance and repair and with easy and simple construction, the cables can produce significant comprehensive economic benefits.

II. Usage of the cables:

1. To be used for high-rise building;

2. To be used for disaster prevention equipments;

3. To be used for tunnel lighting and disaster prevention equipments;

4. To replace copper bus bar with small or medium capacity in various places.

III. Standards of the cables

IEC 60502 Rated Voltage 1 ~ 30KV extruded insulated power cables and accessories (International Electrotechnical Commission standards)

GB 12706 Rated voltage 35KV and below Copper core, Aluminum core plastic insulated power cable (National Standard of the People's Republic of China)

JCS 376 branch cable (Japanese Electric Wire Industry Standard)

General Rules for JIS C2810 indoor wiring electrical connection pipes (Japanese Industrial Standard)

Types of the cables::

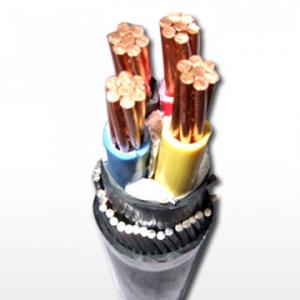

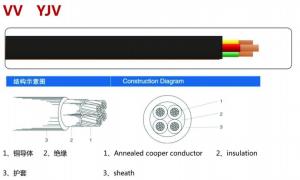

Standard main cables and branch cables are all low-voltage power cables with XLPE or PVC insulation materials (IEC, GB, JIS, BS ... ...), and PVC materials covered on the outer side. Generally, the main cable is single-core or twisted multi-core cable (cables with two to five cores), the branch cables are single-core cables, and may adopt a fire-resistant, flame retardant cables in accordance with the requirements.

Their structures and types are as follows:

No. | Cable Description | Type | |||

single core | three cores twisted type | four cores twisted type | five cores twisted type | ||

1 | PVC insulated PVC sheathed branch cables | FZ-W | FZ-W-3 | FZ-W-4 | FZ-W-5 |

2 | PVC insulated PVC sheathed flame-retardant branch cable | FZ-ZRVV | FZ-ZRVV-3 | FZ-ZRVV-4 | FZ-ZRVV-5 |

3 | PVC insulated PVC sheathed fire-resistant branch cable | FZ-NHVV | FZ-NHVV-3 | FZ-NHVV-4 | FZ-NHVV-5 |

4 | Cross-linked polyethylene insulated PVC sheathed branch cables | FZ-YJV | FZ-YJV-3 | FZ-YJV-4 | FZ-YJV-5 |

5 | Cross-linked polyethylene insulated PVC sheathed flame-retardant branch cables | FZ-ZRYJV | FZ-ZRYJV-3 | FZ-ZRYJV-4 | FZ-ZRYJV-5 |

6 | Cross-linked polyethylene insulated PVC sheathed fire-resistant branch cable | FZ-NHYJV | FZ-NHYJV-3 | FZ-NHYJV-4 | FZ-NHYJV-5 |

- Q:The difference between a fire resistant cable and a general power cable

- We usually say how many square millimeters (wire) refers to the cross-sectional area of the wire core, that is, according to the diameter of the core calculated cross-sectional area. The larger the cross-sectional area of the wire, the greater the capacity of the power transmission.

- Q:I have a simple 400watt amp going to a single 10inch kicker sub, nothing crazy. I need to know what gauge of power cable would be safe. An 8 gauge for example...

- 8 awg would be fine for 400w rms

- Q:I plugged my 110 volt JBL On Stage ipod speakers into a 220 volt socket. The fuse has blown, although I think it has only blown in the power cable and that the Ipod speakers are still fine. I was wondering where I could find a replacement power cable. Thanks for your help

- A 110 ac plug configuration is usually not the same as a 220 ac plug configuration. they look completely different and will not pug into each other...so, I'm not sure how you managed to do that. Now, I am talking about the United States (not sure where you live). Anyway, I'm sure you can find a new power cable online. Or have Best buy order one for you if they don't have it in stock.

- Q:Need advice from tech guys. Can I use laptop charger (20v 3.5A) as adapter with IDE/SATA to USB cable to power 3.5HDD in place of (12v 0.8 A) cheap adapter which just got faulty.

- NO!! Don't do that - I got a hard drive in for repair recently where someone did that - she said it fitted so I thought it would be ok, it's got loads of data I need on that drive can you recover it? I was like - not any more I can't. 20v will blow the hard drive. If the PSU has gone on your external drive your best solution is to take the screws out of the external hard drive casing and open it up. You will find inside you have just a standard SATA hard drive.

- Q:Hey guys,I am going to build a PC around gaming soon, and i was wondering, how many sata and power cables am i going to need for the build, i can't seem to find it anywhere. By that i mean, will i have to buy any extras? I do not know how many come with the mobo and/or PSU.

- You only really need one SATA cable, for your HDD/SSD. Even then there are some hard drives that don't take it. Usually, a hard drive comes with the cable/strip included in the box.

- Q:Okay so I'm production manager for a play in Oxford and I need to have a giant cardboard box drop from the ceiling triggered by an actor with a remote control on stage.I've found a rather nice electromagnet which should do the job which is triggered by a 9V battery. The trigger is an IR unit I'm building which finishes with a relay. The question is can I use a sound XLR cable as the wires in my circuit between the battery with the IR unit and the electromagnet?i.e.Electromagnet -----XLR-----gt; battery -------XLR-----gt; IR unitStandard XLR's do have 3 cables in and surely I only need 2 to complete the circuit.The only reason I'm thinking about using XLRs is that I'm not sure of the distance between things yet and I have plenty of XLRs in many different lengths.Any ideas?

- Yes, you can use your XLR cables and plugs and connectors for a low power 9VDC application. Before you start doing all this, just make sure how many ohms your electromagnet coil has. If it is below 20 ohms, then you can not use a small 9V battery - you need a larger, more powerful battery, such as a stack of 6 AA cells that would easily deliver 1 A or more.

- Q:Most systems are about 1 thousand watts, the red power cable is really thick but then the speaker wire is really thin about 12 gauge, shouldn't the speaker wire be as thick as the power cable?

- No. Wire thickness is about current (and length). And current is inversely related to voltage. When voltage is high (like an amp's speaker outputs) it takes less current to make power. When voltage is low (like a car's alternator/battery) it takes a lot of current to make power. Alternator voltage is ~14v. Amplifier output voltage is commonly 20-40v. Your 1000w example... Say it's a fairly efficient class D mono, 1000w at 2 ohms and 80% efficient. To produce that 1000w requires 1250w from the alternator at around 13v. Ohm's law says current (I) = power(p)/voltage(e) So I = 1250/13, I = 96A On the output side -- I = sqrt(p/r), I = sqrt(1000/2), I = 22A

- Q:I have a SATA hard drive and a SATA cd drive. Is the power supplied through the SATA cable or do i need seporate power cables

- there is a sata power cable that u need to plug in, it comes from ur power supply and is a lil different than the normal power cable .

- Q:I am trying to hook up a LCD display (CPU Temp, USB's in use, Memory Temp/usage, etc) and It came with a 5pin DIN connector for what I assume is the power. I am not sure what I need to do to connect it to the PSU. Any help or ideas?

- you plug it into an open 5 pin coming from the psu. P.S. monie is thinking of a monitor.this is a display for the output of censers

- Q:So i left my xbox on over night (i know i know) and during the night there was either a power outage or surge, cuz all the electronic clocks had been reset. So i went to my xbox, and the light on the power cable box was red and my xbox wouldnt turn on. I havent tried unplugging it yet cuz the wires are behind my tv and a pain in the *** to get to, but i have a feeling this wont help.do i need to get it repaired?

- Unplugging the power brick should sort it out. You can just unplug the end of the wire which goes itno the brick itself rather than the plug socket if that makes it easier.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Assembled prefabricated branch cable FZ-YJV-3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products