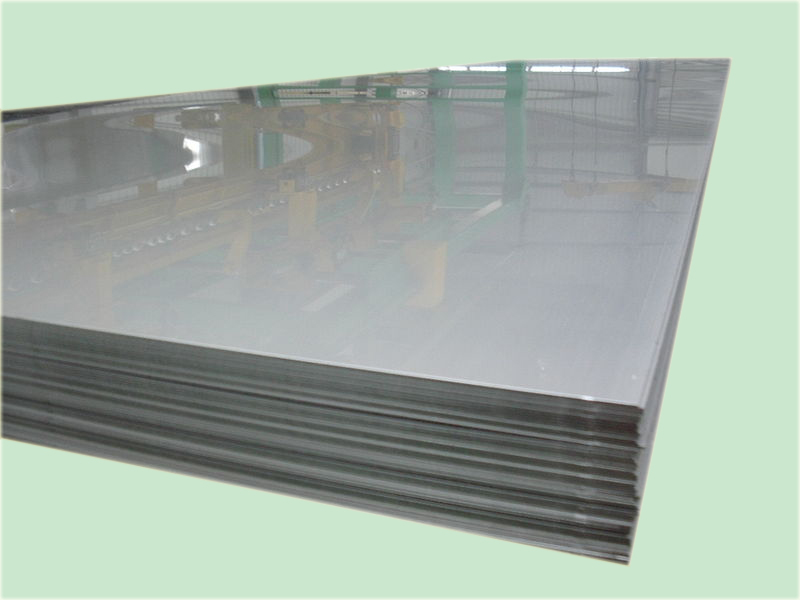

AISI316L Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316L Stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

Max0.03 |

max1.00 |

max2.00 |

max0.045 |

max0.03 |

10.00-14.00 |

16.00-18.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:How wide are stainless steel strips typically available?

- Stainless steel strips are typically available in widths ranging from 0.1 inches (2.5mm) to 24 inches (610mm) depending on the specific requirements and applications.

- Q:Are stainless steel strips suitable for chemical reactors?

- Yes, stainless steel strips are suitable for chemical reactors. Stainless steel is a popular material choice for chemical reactors due to its excellent corrosion resistance properties. It is resistant to many corrosive chemicals, including acids, bases, and salts, making it highly suitable for use in various chemical processes. Stainless steel strips offer good structural strength, thermal stability, and durability, making them an ideal choice for constructing the shell and internal components of chemical reactors. Additionally, stainless steel is easy to clean and maintain, which is crucial in ensuring the integrity and efficiency of the chemical reactor. Overall, stainless steel strips are a reliable and suitable material for chemical reactors, providing the necessary resistance and performance required for handling various chemical reactions.

- Q:Are 111 stainless steel strips suitable for pressure vessels?

- No, 111 stainless steel strips are not suitable for pressure vessels.

- Q:Can stainless steel strips be used in marine vessel construction?

- Yes, stainless steel strips can be used in marine vessel construction. Stainless steel is highly resistant to corrosion and has excellent strength properties, making it suitable for marine environments where exposure to saltwater and harsh conditions is common. Its durability, low maintenance requirements, and aesthetic appeal make stainless steel strips a popular choice for various applications in marine vessel construction.

- Q:Can stainless steel strips be used in the petroleum industry?

- Yes, stainless steel strips can be used in the petroleum industry. Stainless steel is resistant to corrosion and can withstand high temperatures, making it suitable for various applications in the petroleum industry such as pipelines, storage tanks, and equipment used for refining and processing crude oil and natural gas.

- Q:Can stainless steel strips be used in the oil refining industry?

- Indeed, the oil refining industry can utilize stainless steel strips. With its exceptional resistance to corrosion, stainless steel emerges as the perfect material for managing and containing diverse chemicals and substances involved in the oil refining procedure. Moreover, stainless steel exhibits remarkable temperature resistance, a vital characteristic in an industry that frequently confronts high temperatures. Equipment like heat exchangers, distillation columns, and storage tanks commonly employ stainless steel strips, benefiting from their robustness, durability, and resistance to corrosion. Ultimately, stainless steel strips represent a dependable and economical option for the oil refining industry.

- Q:How do stainless steel strips resist stress corrosion cracking?

- Stainless steel strips resist stress corrosion cracking (SCC) due to their unique composition and properties. The primary factor that enables stainless steel to resist SCC is the presence of chromium. Chromium forms a passive oxide layer on the surface of the steel, which acts as a protective barrier against corrosive environments. This passive oxide layer, also known as the chromium oxide film, is self-repairing and continually forms even if it gets damaged or scratched. It effectively prevents the penetration of corrosive agents, such as chlorides, into the material, thereby inhibiting the initiation and propagation of stress corrosion cracking. Furthermore, stainless steel strips also contain nickel, molybdenum, and other alloying elements, which contribute to their enhanced resistance to SCC. Nickel improves the stability of the oxide layer and increases the overall resistance to corrosion. Molybdenum, on the other hand, enhances the material's resistance to pitting and crevice corrosion, which are often associated with SCC. The microstructure of stainless steel also plays a crucial role in its resistance to SCC. Stainless steel strips are typically engineered to have a fine-grained microstructure, which further enhances their resistance to corrosion. Fine grain size reduces the susceptibility to intergranular corrosion, a common precursor to stress corrosion cracking. In addition to the material composition, surface treatments and finishes can also contribute to the resistance against SCC. Passivation, pickling, or electropolishing processes can remove contaminants and enhance the formation of the protective oxide layer on the surface of the stainless steel strips. Overall, stainless steel strips resist stress corrosion cracking through the combined effects of the chromium oxide film, alloying elements, fine-grained microstructure, and appropriate surface treatments. These factors work together to provide excellent corrosion resistance, making stainless steel strips a reliable and durable material choice for various applications.

- Q:Can 111 stainless steel strips be used in the oil and gas industry?

- Indeed, the oil and gas industry can utilize 111 stainless steel strips to great effect. This particular grade of stainless steel, 111 stainless steel, is widely employed due to its commendable resistance against corrosion, remarkable strength, and exceptional malleability. Such attributes render it suitable for a diverse range of applications within the oil and gas sector, encompassing piping, storage tanks, heat exchangers, and various equipment. Moreover, 111 stainless steel strips are capable of withstanding harsh environmental conditions, including exposure to corrosive substances, high temperatures, and pressure, thereby solidifying their status as a dependable choice for the oil and gas industry.

- Q:Can stainless steel strips be used in the production of watches?

- Yes, stainless steel strips can be used in the production of watches. Stainless steel is a popular choice for watch cases and straps due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and polished finish, making it suitable for both traditional and modern watch designs.

- Q:Are stainless steel strips resistant to magnetism?

- Generally, stainless steel strips do not resist magnetism. Although stainless steel itself is not magnetic, it can become magnetic through cold working or the presence of certain elements like nickel, manganese, or iron. These elements can form a magnetic or partially magnetic structure within the stainless steel, making it susceptible to magnetism. However, if the stainless steel strips have low levels of these magnetic elements or undergo annealing (heating and cooling) to remove their magnetic properties, they can be made non-magnetic. Overall, it's crucial to consider the precise composition and treatment of stainless steel strips in order to determine their magnetic properties.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

AISI316L Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords