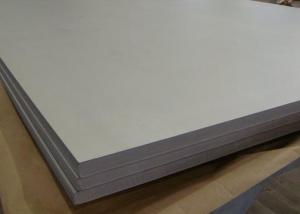

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What are the different thicknesses available for stainless steel strips?

- Stainless steel strips are available in various thicknesses to suit different applications and requirements. Typically, the thickness options for stainless steel strips range from 0.0015 inches (0.0381 mm) to 0.125 inches (3.175 mm) or even thicker, depending on the specific project needs. These thicknesses are commonly measured in gauge, with 22 gauge (0.030 inches) and 16 gauge (0.0625 inches) being the most prevalent. Nonetheless, it should be noted that stainless steel strips can be tailored to meet specific thickness requirements if necessary. The choice of thickness will be influenced by factors such as the intended usage of the strips, the desired level of durability and strength, and any applicable industry standards or regulations that must be adhered to.

- Q:Can stainless steel strips be used in cryogenic applications?

- Yes, stainless steel strips can be used in cryogenic applications. Stainless steel possesses excellent mechanical and thermal properties, including high strength, corrosion resistance, and low thermal conductivity, making it suitable for use in extremely low-temperature environments such as cryogenic applications.

- Q:How do stainless steel strips resist erosion?

- Stainless steel strips have the ability to resist erosion due to their unique composition and properties. Firstly, stainless steel is an alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and thus protecting it from corrosion and erosion. Additionally, stainless steel strips are also highly resistant to acids, alkalis, and various chemicals, which makes them suitable for applications in harsh environments. The presence of other alloying elements such as nickel and molybdenum further enhances the corrosion resistance of stainless steel. Furthermore, the structure of stainless steel, particularly the austenitic stainless steel, provides excellent strength and toughness, making it more resistant to mechanical erosion. The combination of its corrosion resistance and mechanical properties makes stainless steel strips highly durable and able to withstand erosive forces. Moreover, stainless steel strips can be treated with various surface finishes like passivation or electro-polishing, which further improves their resistance to erosion. These treatments remove impurities and contaminants from the surface, creating a smoother and more corrosion-resistant finish. Overall, the ability of stainless steel strips to resist erosion can be attributed to their corrosion-resistant composition, surface treatments, and excellent mechanical properties. These factors make stainless steel an ideal material for various applications where erosion resistance is crucial, such as in the manufacturing of automotive components, kitchen appliances, and chemical processing equipment.

- Q:Can stainless steel strips be used in the production of oil and gas pipelines?

- Yes, stainless steel strips can be used in the production of oil and gas pipelines. Stainless steel is highly corrosion resistant and can withstand harsh environments, making it suitable for use in the oil and gas industry. Its high strength and durability make it ideal for withstanding the pressures and stresses involved in pipeline operations. Additionally, stainless steel's resistance to corrosion and pitting helps maintain the integrity of the pipeline, ensuring a longer service life and minimizing the risk of leaks or failures.

- Q:What are the main stainless steel belt used in the industry and products?

- Judging from the industry composition of stainless steel consumption, the automotive industry is the fastest growing area of stainless steel application. Chinese household electrical appliance industry is a potential big market for stainless steel applications. In addition, the demand for stainless steel in the water industry, construction and construction industry, environmental protection industry and industrial facilities will also increase year by year. Specifically:

- Q:What is the weight of stainless steel strips?

- The dimensions and thickness of stainless steel strips can cause variations in their weight. In general, stainless steel has a density of approximately 7.93 grams per cubic centimeter. In order to determine the weight of a stainless steel strip, it is necessary to have knowledge of its length, width, and thickness. By multiplying the strip's area by its thickness and density, one can ascertain its weight.

- Q:Are stainless steel strips suitable for marine applications?

- Yes, stainless steel strips are highly suitable for marine applications. Stainless steel is known for its exceptional corrosion resistance, which makes it a preferred material for marine environments where exposure to saltwater, humidity, and other corrosive elements is common. Stainless steel strips have excellent strength and durability, allowing them to withstand harsh conditions, high temperatures, and mechanical stress commonly encountered in marine applications. Additionally, stainless steel's low maintenance requirements and aesthetic appeal make it a popular choice for various marine components such as boat fittings, marine hardware, marine fasteners, and shipbuilding.

- Q:Are stainless steel strips suitable for architectural roof cladding?

- Indeed, architectural roof cladding can be effectively accomplished with stainless steel strips. Thanks to its exceptional durability and resistance to corrosion, stainless steel proves to be an optimal choice for outdoor installations like roof cladding. It endures inclement weather conditions, such as rain, snow, and UV radiation, without succumbing to degradation or compromising its aesthetic appeal. Furthermore, architects can select from a diverse array of finishes and colors, providing them with ample options to achieve their desired design aesthetic. The versatility, strength, and minimal upkeep demands of stainless steel strips render them an exceptional option for architectural roof cladding.

- Q:Can stainless steel strips be used for architectural sculptures?

- Yes, stainless steel strips can be used for architectural sculptures. Stainless steel is a versatile and durable material that can be easily manipulated into various shapes and forms. Its corrosion-resistant properties make it ideal for outdoor sculptures, as it can withstand harsh weather conditions without rusting or deteriorating. Stainless steel strips can be cut, bent, and welded to create intricate designs and unique sculptures. The strips can be formed into different shapes, such as curves, waves, or straight lines, allowing for endless creative possibilities. Additionally, stainless steel can be polished or brushed to achieve different finishes, giving the sculptures a sleek and modern look. Architectural sculptures often require materials that are not only visually appealing but also long-lasting and low-maintenance. Stainless steel meets these criteria, making it an excellent choice for architectural sculptures. Its strength and resistance to corrosion make it suitable for both indoor and outdoor installations. Furthermore, stainless steel's reflective surface can create interesting visual effects, especially when combined with lighting. The sculpture can capture and reflect the surrounding environment, enhancing its visual impact and creating a dynamic and engaging experience for viewers. In conclusion, stainless steel strips can indeed be used for architectural sculptures. Their versatility, durability, and aesthetic appeal make them a popular choice for artists and architects looking to create unique and long-lasting sculptures.

- Q:Can stainless steel strips be used for automotive suspension components?

- Yes, stainless steel strips can be used for automotive suspension components. Stainless steel is known for its high strength, corrosion resistance, and durability, making it a suitable material for various automotive applications, including suspension components. Stainless steel strips can be used to manufacture springs, brackets, and other parts that are essential for the suspension system. These components need to withstand heavy loads, vibrations, and exposure to various environmental conditions, and stainless steel's properties make it a reliable choice for such demanding applications. Additionally, stainless steel's resistance to corrosion ensures that the suspension components will have a longer lifespan, even in harsh conditions. Therefore, stainless steel strips are a viable option for automotive suspension components.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 1989 |

| Annual Output Value | Above US$160 Thousand |

| Main Markets | Europe, East Asia and Southeast Asia |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 14,500 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords