Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold rolled stainless steel Coil, which can be used

directly in many places. Stainless Steel (Stainless Steel) is short for acidproof Stainless Steel, resistant to weak corrosive medium

such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

The purpose of the different requirement for welding performance are different.1 Kind of tableware generally do not require the performance

of welding, even including some pot class enterprise. But the vast majority of products all need raw materials welding performance is good,

like the 2 kinds of tableware, thermos flask, steel pipes, water heaters, water dispensers, etc.

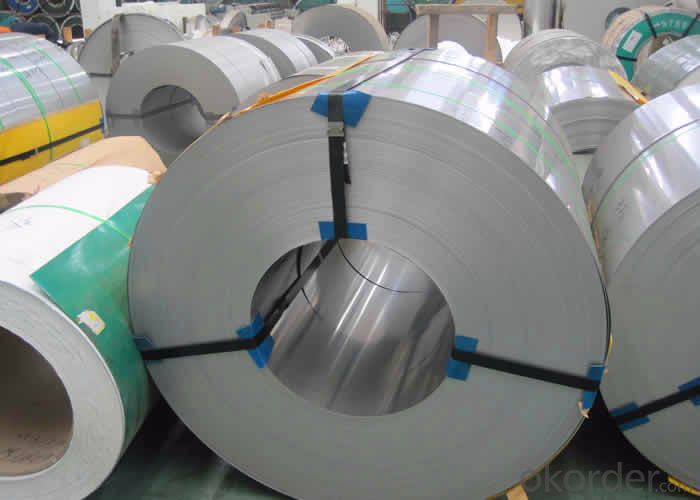

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

Austenitic stainless steel The title Chromium is more than 18%, still contain about 8% of the nickel and small amounts of molybdenum,

titanium, nitrogen and other elements. Good comprehensive performance, corrosion resistant to a variety of media. Number of austenitic

stainless steel is commonly used one cr18ni9, 0 cr19ni9, etc. In the Wc < 0.08% 0 cr19ni9 steel, steel grade is marked as "0". This class

contains large amounts of Ni and Cr in steel, make steel in austenitic state at room temperature. This kind of steel has good plasticity

and toughness, weldability and corrosion resistance and nonmagnetic or weak magnetic, the corrosion resistance in oxidizing and reducing

medium are good, used to make acid equipment, such as corrosion resistant containers and equipment lining, pipelines, nitric acid

resistant equipment parts, etc., also can be used as the main body of watches and clocks jewelry stainless steel material. Austenitic

stainless steel with solid solution treatment, the steel heating to 1050 ~ 1150 ℃, then water-cooled or air-cooled, for single-

phase austenitic organization.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM

casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict

quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term

is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as soon as possible. The specific time of receiving

is related to the state and position of customers. Commonly 20 to 40 working days can be served.

- Q:What are the factors affecting the fatigue strength of 111 stainless steel strips?

- The fatigue strength of 111 stainless steel strips may be impacted by several factors. These factors include the material composition, surface finish, heat treatment, presence of defects, loading conditions, environmental factors, manufacturing processes, and design considerations. 1. Material composition plays a significant role in determining the fatigue strength of stainless steel strips. The presence of alloying elements like chromium, nickel, and molybdenum can have a notable effect on fatigue strength. Generally, higher levels of these elements result in increased fatigue strengths. 2. The fatigue strength of stainless steel strips can be influenced by their surface finish. A smoother surface finish can lessen stress concentrations and enhance fatigue resistance. 3. The heat treatment process employed in the manufacturing of stainless steel strips can impact their fatigue strength. Proper heat treatment can improve the microstructure of the material, leading to enhanced fatigue resistance. 4. Defects such as cracks, notches, or inclusions significantly reduce the fatigue strength of stainless steel strips. These defects act as stress concentrators and cause premature failure under cyclic loading. 5. Loading conditions, including stress amplitude, mean stress, and loading frequency, can affect the fatigue strength of stainless steel strips. Higher stress amplitudes, mean stresses, or frequencies can decrease the fatigue life of the material. 6. Environmental factors, such as temperature, humidity, and the presence of corrosive media, can accelerate the initiation and propagation of fatigue cracks in stainless steel strips. 7. The manufacturing processes used in producing stainless steel strips, such as rolling, annealing, and surface treatments, can influence their fatigue strength. Proper control of these processes is necessary to ensure optimal fatigue performance. 8. Design considerations, such as the geometry, thickness, and stress concentration areas of stainless steel strips, can affect their fatigue strength. Implementing design modifications like fillets or radii at stress concentration areas can enhance fatigue resistance. In conclusion, understanding and managing these factors are essential for optimizing the fatigue strength of 111 stainless steel strips and ensuring their dependable performance under cyclic loading conditions.

- Q:Can stainless steel strips be used for decorative trims?

- Yes, stainless steel strips can be used for decorative trims. Due to their sleek and shiny appearance, stainless steel strips are often used to add a modern and stylish touch to various decorative applications, such as on furniture, appliances, or architectural elements.

- Q:Can stainless steel strips be used in the production of kitchen utensils?

- Certainly, the utilization of stainless steel strips in the manufacturing of kitchen utensils is indeed possible. Stainless steel has become widely preferred for kitchen utensils owing to its numerous advantageous qualities. Its resistance to corrosion, heat, and ability to maintain hygiene make it an ideal material for food preparation and cooking purposes. The malleability of stainless steel strips allows for easy shaping and crafting of a diverse range of utensil designs such as spoons, forks, knives, spatulas, tongs, and an array of others. Furthermore, the durability and longevity of stainless steel utensils guarantee their ability to endure the demands of everyday kitchen usage.

- Q:Can stainless steel strips be used in textile machinery?

- Indeed, textile machinery can utilize stainless steel strips. Stainless steel, a highly flexible material, boasts remarkable resistance against corrosion, significant strength, and outstanding durability. These attributes render it suitable for a myriad of purposes in the textile sector, encompassing textile machinery. Weaving machines, spinning machines, knitting machines, and other machinery components that necessitate robustness and resilience against deterioration can all accommodate stainless steel strips. Moreover, stainless steel strips are effortlessly cleaned and maintained, thereby serving as an impeccable choice for textile machinery that encounters fibers, dyes, and various chemicals.

- Q:What are the factors affecting the thermal conductivity of 111 stainless steel strips?

- There are several factors that can affect the thermal conductivity of 111 stainless steel strips. 1. Chemical composition: The elemental composition of the stainless steel, especially the presence of alloying elements, can significantly impact its thermal conductivity. Different elements can either enhance or hinder the flow of heat within the material. 2. Microstructure: The microstructure of stainless steel, including the size, distribution, and shape of its grains, affects its thermal conductivity. A more uniform and fine-grained microstructure typically results in higher thermal conductivity. 3. Temperature: The thermal conductivity of stainless steel can vary with temperature. Generally, thermal conductivity decreases as the temperature increases due to increased lattice vibrations and phonon scattering, which hinder the flow of heat. 4. Heat treatment: The heat treatment process used during the production of stainless steel strips can influence their thermal conductivity. Specific heat treatments, such as annealing or quenching, can modify the microstructure and thereby impact thermal conductivity. 5. Alloying elements: The addition of certain alloying elements, such as nickel or copper, can enhance the thermal conductivity of stainless steel. These elements can improve the mobility of electrons or phonons, leading to better heat conduction. 6. Surface finish: The surface finish of stainless steel strips can affect their thermal conductivity. A smooth surface with minimal imperfections or roughness allows for better thermal contact and heat transfer. 7. Thickness: The thickness of stainless steel strips can also affect their thermal conductivity. Thinner strips tend to have higher thermal conductivity due to shorter heat transfer paths. 8. Impurities and defects: The presence of impurities or defects in the stainless steel, such as inclusions or voids, can hinder the flow of heat and reduce thermal conductivity. It is important to consider these factors when selecting and utilizing stainless steel strips for applications that require efficient heat transfer.

- Q:Are 111 stainless steel strips suitable for chemical storage tanks?

- No, 111 stainless steel strips are not suitable for chemical storage tanks. 111 stainless steel is not specifically designed to resist corrosion or withstand the aggressive chemical environments that are typically found in storage tanks. It is important to use stainless steel grades that are specifically designed for chemical storage applications, such as 304 or 316 stainless steel, which have higher resistance to corrosion and chemical attacks.

- Q:What is the cost of stainless steel strips?

- The cost of stainless steel strips can vary depending on several factors such as the grade of stainless steel, the thickness and width of the strips, and the quantity being purchased. Additionally, market conditions and the supplier's pricing strategy can also affect the cost. Generally, stainless steel strips can range in price from a few dollars per pound to several hundred dollars per pound. It is recommended to contact various suppliers and provide them with the specific requirements to obtain accurate pricing information.

- Q:What is the maximum temperature stainless steel strips can withstand?

- The maximum temperature that stainless steel strips can withstand depends on the specific grade of stainless steel being used. Generally, stainless steel is known for its high heat resistance and can withstand temperatures up to 1450°C (2642°F) without significant structural changes or loss of mechanical properties. However, it's important to note that prolonged exposure to high temperatures can lead to oxidation and scaling on the surface of stainless steel, which may affect its performance. Additionally, different grades of stainless steel have varying levels of heat resistance, so it is crucial to consult the manufacturer's specifications or a materials engineer for accurate information on the maximum temperature tolerance of specific stainless steel strips.

- Q:How is corrosion resistance achieved in stainless steel strips?

- Corrosion resistance in stainless steel strips is achieved through the presence of chromium, which forms a passive oxide layer on the surface of the steel. This oxide layer acts as a protective barrier, preventing the underlying metal from coming into contact with corrosive agents and thus enhancing its resistance to corrosion.

- Q:What are the different cutting methods for stainless steel strips?

- When cutting stainless steel strips, there are several methods available depending on specific requirements and desired outcomes. Some commonly used methods include: 1. Shearing: This traditional method involves using sharp blades to cut through the stainless steel. Shearing is ideal for thinner strips, providing a clean and straight cut. However, it may not be suitable for thicker or harder stainless steel. 2. Laser cutting: Laser cutting is a precise and efficient method that utilizes a laser beam to cut through the stainless steel. It is commonly used for intricate and complex shapes, offering high levels of accuracy and control. Laser cutting is suitable for both thin and thick stainless steel strips. 3. Waterjet cutting: This method utilizes a high-pressure stream of water mixed with an abrasive material to cut through the stainless steel. It is a versatile method that can be used for various thicknesses and shapes. Waterjet cutting provides clean and precise cuts without causing heat distortion or altering the properties of the stainless steel. 4. Plasma cutting: Plasma cutting involves using a jet of ionized gas to cut through the stainless steel. It is a fast and efficient method that can be used for both thin and thick strips. Plasma cutting is particularly suitable for stainless steel strips with high alloy content or hardening properties. 5. Saw cutting: Saw cutting utilizes a rotating saw blade to cut through the stainless steel. It is a versatile method that can be used for various thicknesses and shapes. Saw cutting provides fast and efficient cuts, but it may not be as precise as other methods and may cause some burring or rough edges. Overall, when selecting a cutting method for stainless steel strips, factors such as material thickness, hardness, desired precision, and project requirements should be carefully considered. It is advisable to consult with experts to determine the most suitable cutting method for a specific application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords