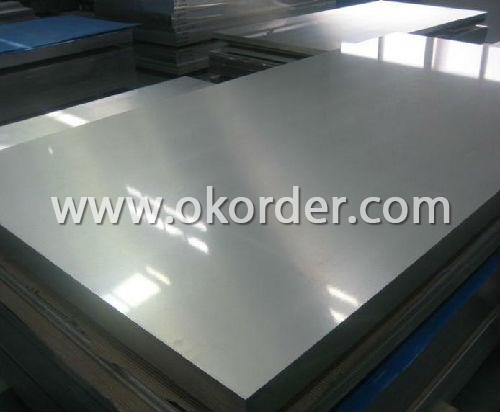

AISI 304 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Sheet

1. Chemical composition of AISI 304 Stainless Steel Sheet

C | Si | Mn | P | S | Ni | Cr |

max0.08 | max1.00 | max2.00 | max0.045 | max0.03 | 8.00-10.50 | 18.00-20.00 |

2. Mechanical properties of AISI 304 Stainless Steel Sheet

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

3. Standard of AISI 304 Stainless Steel Sheet : AISI, ASTM, GB, EN, DIN, JIS

4. Surface of AISI 304 Stainless Steel Sheet : 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of AISI 304 Stainless Steel Sheet :

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of AISI 304 Stainless Steel Sheet : 1 Ton

7. Payment terms of AISI 304 Stainless Steel Sheet : T/T or L/C

8. Packing of AISI 304 Stainless Steel Sheet : Seaworthy package with wooden or Iron pallets with the paper and the steel strip,

or as customers' request.

9. Delivery time of AISI 304 Stainless Steel Sheet : Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q:What are the common uses of stainless steel strips in the electronics industry?

- Stainless steel strips find various uses in the electronics industry due to their exceptional properties and versatility. One common application of stainless steel strips in the electronics industry is as shielding material. Electromagnetic interference (EMI) can negatively affect the performance of electronic devices, and stainless steel strips are used as shielding to minimize this interference. They provide excellent electromagnetic shielding properties, preventing the leakage or absorption of electromagnetic radiation, and ensuring the smooth functioning of electronic components. Another common use of stainless steel strips in the electronics industry is for connectors. Stainless steel strips are often used as connector pins or terminals due to their high electrical conductivity and corrosion resistance. They provide a reliable and durable connection between different electronic components, ensuring efficient transmission of electrical signals. Moreover, stainless steel strips are utilized in the manufacturing of springs and contacts in various electronic devices. Their exceptional elasticity and resilience make them suitable for applications where electrical contacts need to be maintained under pressure. Stainless steel strips can withstand repeated bending and stretching without losing their shape or functionality, making them ideal for use in switches, relays, and other electronic components. Additionally, stainless steel strips are employed in the production of battery contacts. These contacts need to be corrosion-resistant and have excellent electrical conductivity to ensure proper functioning of the battery. Stainless steel strips fulfill these requirements, providing a reliable current flow and preventing any potential damage or degradation caused by corrosion. In summary, stainless steel strips have a wide range of uses in the electronics industry. They are commonly used as shielding material to minimize electromagnetic interference, as connectors for efficient electrical transmission, as springs and contacts in various electronic devices, and as battery contacts for reliable performance. The exceptional properties of stainless steel, such as corrosion resistance, electrical conductivity, and elasticity, make them an ideal choice for various electronic applications.

- Q:Can stainless steel strips be etched or engraved?

- Yes, stainless steel strips can be etched or engraved using various techniques such as chemical etching, laser engraving, or mechanical engraving.

- Q:Are stainless steel strips easy to clean and maintain?

- Yes, stainless steel strips are easy to clean and maintain. Stainless steel is known for its resistance to corrosion, stains, and rust, making it an ideal material for various applications, including strips. To clean stainless steel strips, you can use a mild detergent or soap with warm water and a soft cloth or sponge. Gently scrub the surface in the direction of the grain to avoid scratching. Afterward, rinse the strips thoroughly and wipe them dry to prevent water spots. In terms of maintenance, stainless steel strips require minimal effort. Regular cleaning is usually sufficient to keep them in good condition. However, if you notice any stubborn stains or marks, you can use stainless steel cleaners or polishes specifically designed for this purpose. These products can help restore the shine and eliminate any residue or imperfections. Furthermore, stainless steel is highly durable, so it doesn't require special treatments or coatings to maintain its quality. It is also resistant to heat, making it suitable for use in various environments, including kitchens and manufacturing facilities. Overall, stainless steel strips are relatively easy to clean and maintain due to their inherent properties. By following proper cleaning techniques and using appropriate products, you can ensure that your stainless steel strips remain in excellent condition for a long time.

- Q:What are the common surface defects in stainless steel strips?

- Some common surface defects in stainless steel strips include scratches, pits, and surface roughness. Scratches can occur during handling, transportation, or processing of the strips. Pits are small depressions or cavities on the surface, often caused by corrosion or impurities. Surface roughness can result from improper grinding, polishing, or finishing processes. Other defects may include stains, discoloration, or uneven coating. It is important to carefully inspect stainless steel strips for these defects as they can affect the appearance, performance, and durability of the material.

- Q:Can stainless steel strips be used in automotive exhaust systems?

- Yes, stainless steel strips can be used in automotive exhaust systems. Stainless steel is a popular material choice for exhaust systems due to its high corrosion resistance and durability. It can withstand extreme temperatures and harsh conditions, making it suitable for the exhaust system's demanding environment. Stainless steel strips are often used for the construction of exhaust pipes, mufflers, and other components due to their strength and ability to resist rust and corrosion. Additionally, stainless steel strips can be easily formed, welded, and shaped to meet the specific requirements of an exhaust system, making them an ideal choice for automotive applications.

- Q:What are the weight and density of stainless steel strips?

- The weight and density of stainless steel strips can vary depending on their thickness and dimensions. Generally, stainless steel has a density of around 7.9 grams per cubic centimeter (g/cm3). To determine the weight of a stainless steel strip, you would need to know its dimensions and multiply them by the density to get the weight per unit length or area.

- Q:Can stainless steel strips be used in extreme temperature conditions?

- Stainless steel strips are capable of being used in extreme temperature conditions. This material is versatile and durable, able to endure a wide range of temperatures. Its exceptional heat resistance properties make it suitable for both high and low-temperature environments. Stainless steel strips maintain their structural integrity and mechanical properties even under intense heat. They also exhibit remarkable resistance to thermal expansion and contraction, ensuring stability in extreme temperature conditions. Moreover, stainless steel has excellent resistance to corrosion, oxidation, and scaling, making it an excellent choice for applications that involve temperature fluctuations and exposure to harsh environments. In conclusion, stainless steel strips are a dependable and efficient option for various industries that require materials capable of withstanding extreme temperatures.

- Q:Can stainless steel strips be used in the oil refinery equipment?

- Yes, stainless steel strips can be used in oil refinery equipment. Stainless steel is highly resistant to corrosion and high temperatures, making it suitable for use in the harsh conditions of an oil refinery. It has excellent strength and durability, which allows it to withstand the corrosive and abrasive nature of oil refining processes. Additionally, stainless steel strips can be easily formed and fabricated into various shapes and sizes required for oil refinery equipment.

- Q:Can stainless steel strips be used in the brewing industry?

- Yes, stainless steel strips can be used in the brewing industry. Stainless steel is a popular material choice in the brewing industry due to its corrosion resistance, durability, and hygienic properties. Stainless steel strips can be used for various applications in breweries, including equipment fabrication, tanks, piping, and fittings.

- Q:How are 111 stainless steel strips manufactured?

- The manufacturing process for 111 stainless steel strips encompasses several stages. Initially, raw materials are carefully chosen, typically including iron ore, chromium, nickel, and other alloying elements. These materials are precisely measured and blended in the desired proportions to create the stainless steel alloy. Subsequently, the raw materials are melted in a high-temperature furnace. The resulting molten metal is then poured into a continuous casting machine, which shapes it into long slabs or billets. These slabs are allowed to cool and solidify. Once solidified, the slabs are reheated in a furnace to a specific temperature, rendering them more malleable. They are then passed through a hot rolling mill, where they are reduced in thickness and elongated into long strips. The rolling process is repeated multiple times until the desired thickness and quality are achieved. When the strips reach the desired thickness, they undergo annealing in a heat treatment furnace. Annealing helps alleviate internal stresses and enhance the mechanical properties of the stainless steel. This process involves heating the strips to a specific temperature and gradually cooling them. To improve the surface finish and eliminate imperfections, the strips are subjected to a pickling process. This entails immersing them in an acid solution that removes scale, oxides, and other impurities from the surface. Following pickling, the strips undergo a cold rolling process. This involves passing them through a series of high-pressure rollers, further reducing their thickness and enhancing their surface finish. To attain the desired dimensions and tolerances, the strips are subsequently cut into the required lengths using shearing or slitting machines. Depending on the specific application requirements, they may also undergo additional processes such as edge trimming, edge rounding, or surface polishing. Finally, the finished stainless steel strips undergo a thorough quality inspection, which includes checking for dimensional accuracy, surface defects, and mechanical properties. They are then carefully packaged and prepared for shipment to customers across various industries, such as automotive, construction, appliances, and many more.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

AISI 304 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords