AISI 201 Stainless Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 201 Stainless Steel Coil

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.15 |

max1.00 |

5.50-7.50 |

max0.06 |

max0.03 |

max1.00 |

16.00-18.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

245 |

640 |

40 |

253 |

100 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms:T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:What is the difference between stainless steel strip and stainless steel sheet?

- The main difference between stainless steel strip and stainless steel sheet lies in their dimensions and thickness. Stainless steel strip is typically thinner and narrower compared to stainless steel sheet. It is often used for various applications such as electrical components, automotive parts, and small household appliances. On the other hand, stainless steel sheet is thicker and larger in size, making it suitable for applications that require a more robust and sturdy material, such as construction, industrial equipment, and kitchen appliances. Both stainless steel strip and stainless steel sheet offer excellent corrosion resistance and durability, but their different dimensions make them better suited for specific applications.

- Q:Are stainless steel strips suitable for solar panel mounting?

- Indeed, solar panel mounting can be effectively achieved using stainless steel strips. Renowned for its enduring nature, resistance against corrosion, and remarkable strength, stainless steel emerges as an optimal selection for outdoor purposes such as solar panel placement. These strips are capable of withstanding severe weather conditions encompassing strong winds, heavy rain, and snow, without succumbing to corrosion or degradation over time. Moreover, stainless steel furnishes a steadfast and secure foundation for solar panels, guaranteeing their firm positioning and efficient utilization of sunlight for energy production. In summary, stainless steel strips present themselves as a dependable and enduring alternative for the mounting of solar panels.

- Q:What kind of plastic surface friction and wear in stainless steel belt is relatively small?

- Plastic itself than metal soft, so it is not bad stainless steel, and if the metal surface smoothness is low (micro Burr) will be broken plastic surface, in the contact surface, if there are hard particles will also be broken metal surface.

- Q:What is the thickness range of stainless steel strips?

- The thickness range of stainless steel strips can vary depending on the specific application and requirements. Generally, stainless steel strips are available in thicknesses ranging from 0.02 millimeters to 5 millimeters. However, it is important to note that custom thicknesses can also be manufactured to meet specific needs. The selection of the appropriate thickness depends on factors such as the intended use, structural requirements, and desired aesthetics.

- Q:What are the different types of welding processes used for stainless steel strips?

- For stainless steel strips, there are various welding processes commonly utilized. These processes encompass: 1. TIG (Tungsten Inert Gas) Welding: Renowned for its capability to create precise and high-quality welds, TIG welding is favored for stainless steel strips. It employs a non-consumable tungsten electrode to generate the arc and an inert gas, like argon, to safeguard the weld pool against impurities. 2. MIG (Metal Inert Gas) Welding: Another prevalent technique for stainless steel strips is MIG welding, which involves a continuous feed of consumable wire electrode through a welding gun. The electrode melts and unites the base metals while an inert gas shield prevents oxidation in the weld area. 3. Plasma Arc Welding: Plasma arc welding is highly versatile and suitable for stainless steel strips. It utilizes a concentrated and high-temperature plasma arc to fuse the metals together. This method provides excellent control and precision, making it well-suited for thin stainless steel strips. 4. Resistance Welding: Resistance welding relies on the heat generated from electrical resistance to join metals. This process can be applied to stainless steel strips using spot or seam welding techniques. It is commonly employed in high-speed production applications. 5. Laser Welding: Laser welding is a contactless process that employs a highly focused laser beam to join stainless steel strips. It offers exceptional precision and control, making it ideal for intricate or delicate welds. Industries that require a superior finish, both aesthetically and in terms of quality, often use laser welding. These represent only a fraction of the welding processes available for stainless steel strips. The selection of a particular process relies on factors such as strip thickness, desired weld quality, production requirements, and the intended application of the stainless steel strips.

- Q:Can 111 stainless steel strips be used in marine environments?

- Yes, 111 stainless steel strips can be used in marine environments. 111 stainless steel is a low carbon, high chromium stainless steel that offers excellent resistance to corrosion in various environments, including marine environments. It has good strength and toughness, making it suitable for use in marine applications such as boat fittings, marine hardware, and offshore structures. Additionally, 111 stainless steel has good weldability and can withstand exposure to saltwater and other corrosive elements commonly found in marine environments. However, it is important to properly maintain and clean the stainless steel strips to ensure their long-term performance in marine environments.

- Q:Can 111 stainless steel strips be used in the construction industry?

- Yes, 111 stainless steel strips can be used in the construction industry. Stainless steel is a highly versatile and durable material that is commonly used in various construction applications. Its corrosion-resistant properties make it suitable for both indoor and outdoor projects. Stainless steel strips can be used for cladding, roofing, wall panels, and other architectural features. Additionally, stainless steel's strength and resistance to extreme temperatures make it an ideal choice for structural components such as beams, columns, and supports. The specific grade of stainless steel, such as 111, may have different mechanical properties that could influence its suitability for certain applications. It is important to consult with a structural engineer or construction professional to determine if 111 stainless steel strips meet the required specifications for a particular project.

- Q:Can stainless steel strips be used in the construction equipment industry?

- Certainly, the construction equipment industry can utilize stainless steel strips. Renowned for its superb corrosion resistance, durability, and strength, stainless steel proves to be suitable for a wide range of construction equipment applications. In particular, stainless steel strips find utility in reinforcing structures, fabricating components, and crafting bespoke parts for construction machinery. Their impressive resistance to rust and corrosion renders them perfect for demanding outdoor tasks and heavy-duty applications. Moreover, thanks to stainless steel's exceptional strength-to-weight ratio, lightweight yet robust equipment can be manufactured, thereby enhancing efficiency and performance. All in all, stainless steel strips emerge as a valuable asset within the construction equipment industry due to their durability, corrosion resistance, and adaptability.

- Q:Why does stainless steel carry magnetism?

- In fact, there is also a stainless steel magnet can not afford, that is, high manganese or nitrogen and low nickel or nickel free stainless steel, chromium, manganese austenitic stainless steel, so it can not be based on whether or not to determine whether the magnetic stainless steel

- Q:Are stainless steel strips resistant to galvanic corrosion?

- Stainless steel strips possess resistance against galvanic corrosion. The reason behind this lies in the fact that stainless steel is an alloy fortified with chromium, which generates a passive protective layer on its surface. This layer acts as a shield, obstructing any direct contact between the steel and other metals, thereby diminishing the likelihood of galvanic corrosion. Furthermore, stainless steel exhibits remarkable resistance to corrosion in general, making it an optimal selection for scenarios prone to galvanic corrosion, such as marine environments or situations involving dissimilar metals.

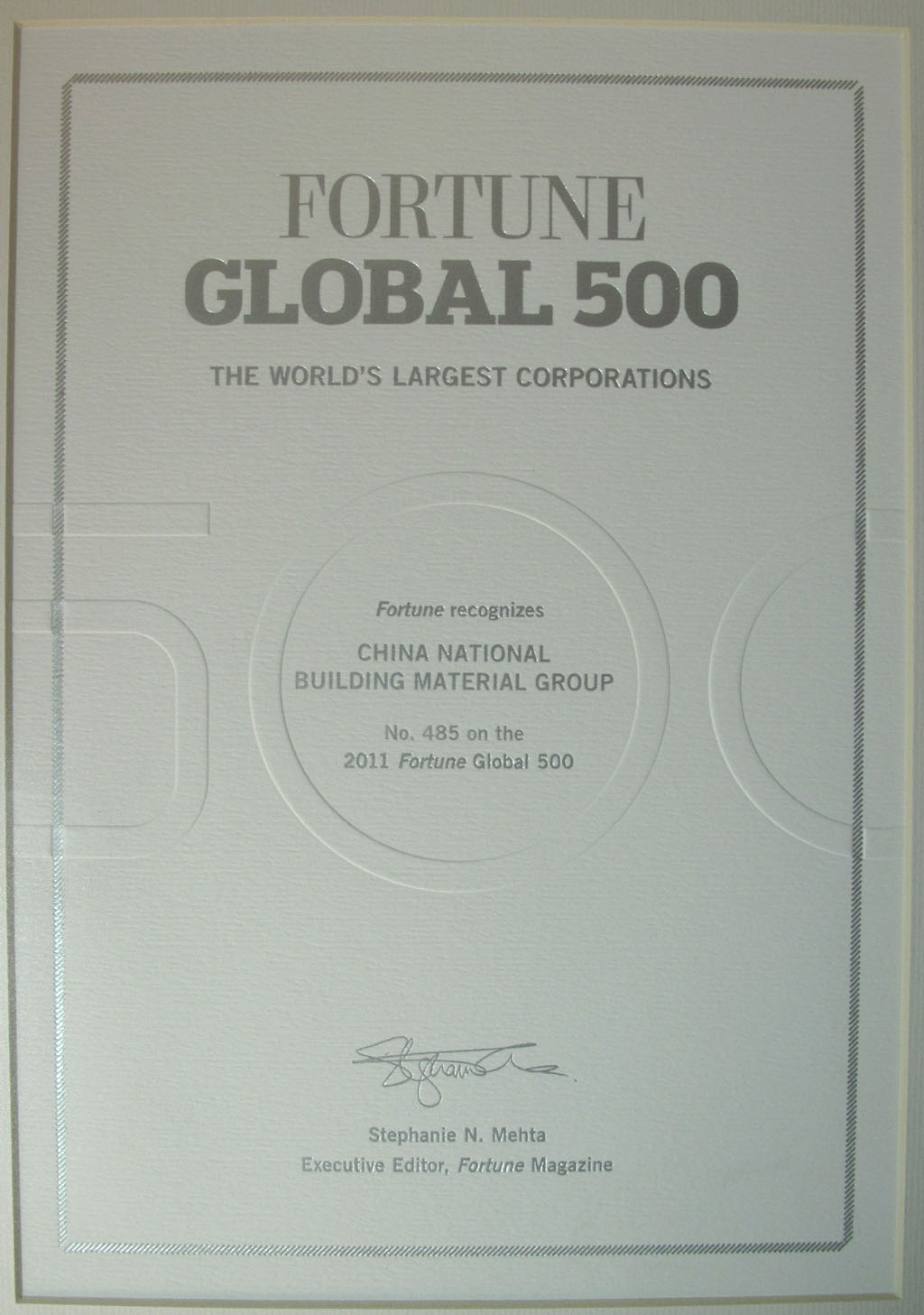

1. Manufacturer Overview |

|

|---|---|

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

AISI 201 Stainless Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords