Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Q345 U shaped Channel Steel Hot Rolled Channel

Main Structure of Hot Rolled Channel

| 1.Product size | Size : 5#--40# | ||||

| 2.Product length | Lengths : 6m--12m | ||||

| 3.product standard | Standard : GB, ASTM, JIS, DIN | ||||

| 4.product Grade | Grades : Q235B, Q345B, SS400 | ||||

| 5.Application | Used or building structures, vehicle | ||||

| manufacturing and other industrial structures | |||||

| 6.Customized requirement | Can produce special specification products | ||||

| as per our customers' requirement | |||||

| 7.Delivery time | 15-30 days after recieve the LC or pre-paid | ||||

| 8.Detail Package | Bundles, seaworthy wooden cases with or without | ||||

| edge protector, steel hoop and seals, or as per | |||||

| customers' requirements | |||||

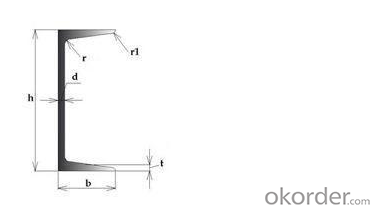

Drawings And Detail Datas (help to know more detail information)

Specification:

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

FAQ:

How's your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture:

- Q:What are the load capacities of stainless steel angles?

- The load capacity of stainless steel angles may vary depending on a variety of factors, including the size, thickness, and grade of the stainless steel utilized. When it comes to structural applications where strength and durability are crucial, stainless steel angles are commonly employed. In general, due to their inherent strength and resistance to deformation, stainless steel angles possess the ability to bear heavy loads. However, the load capacity can also be affected by the installation method and the type of attachment employed. To determine the specific load capacities for stainless steel angles, it is essential to refer to engineering specifications and load charts provided by manufacturers or industry standards. These charts typically furnish load capacity values based on the size and grade of stainless steel angles, as well as the type of loading (such as axial or bending) and the necessary safety factor for the given application. Furthermore, it is advisable to enlist the assistance of a professional engineer or structural designer who can accurately evaluate and calculate load capacities based on the unique requirements and conditions of the project.

- Q:Are stainless steel angles resistant to sulfuric acid?

- Yes, stainless steel angles are generally resistant to sulfuric acid. Stainless steel is known for its excellent corrosion resistance, and this includes resistance to sulfuric acid. However, the level of resistance may vary depending on the grade of stainless steel used. Grades such as 304 and 316 are commonly used in applications involving sulfuric acid due to their higher resistance to corrosion. It is important to note that while stainless steel angles may be resistant to sulfuric acid, the concentration, temperature, and duration of exposure can still affect their performance. Therefore, it is always advisable to consult with a materials engineer or specialist to determine the most suitable grade of stainless steel for specific sulfuric acid applications.

- Q:What are the machining techniques used for stainless steel angle?

- There are several machining techniques that can be used for stainless steel angle. 1. Turning: This process involves rotating the stainless steel angle against a cutting tool to remove material and create the desired shape. It is commonly used for cutting and shaping the outside diameter of the angle. 2. Milling: Milling involves using a rotating cutting tool to remove material from the stainless steel angle. It can be used to create slots, pockets, and other complex shapes on the surface of the angle. 3. Drilling: Drilling is a common machining technique used to create holes in stainless steel angle. It involves rotating a cutting tool called a drill bit against the angle to remove material and create the desired hole. 4. Tapping: Tapping is used to create internal threads in stainless steel angle. It involves rotating a cutting tool called a tap into a pre-drilled hole, which cuts threads into the material. 5. Grinding: Grinding is a machining technique used to smooth the surface of stainless steel angle. It involves using a rotating abrasive wheel to remove material and create a smooth, polished finish. 6. Bending: Bending is a technique used to shape stainless steel angle by applying force to it. This can be done through various methods such as press bending, roll bending, or heat bending. 7. Laser cutting: Laser cutting is a precise and efficient machining technique used to cut stainless steel angle. It involves using a high-powered laser beam to melt and vaporize the material along a predetermined path, creating the desired shape. These are just a few examples of the machining techniques that can be used for stainless steel angle. The specific technique chosen will depend on the desired outcome, precision requirements, and the equipment and expertise available.

- Q:What are the common industries that use stainless steel angles?

- The common industries that use stainless steel angles include construction, automotive, aerospace, marine, food processing, and pharmaceutical.

- Q:Can stainless steel angle be used in pharmaceutical storage systems?

- Indeed, pharmaceutical storage systems can utilize stainless steel angles. Due to its exceptional resistance to corrosion, stainless steel proves to be an optimal material for storing pharmaceutical products that necessitate a sanitary and uncontaminated setting. The durability and effortless cleanliness of stainless steel angles render them appropriate for pharmaceutical storage systems that prioritize hygiene. Moreover, stainless steel remains non-reactive and does not emit any hazardous substances, thus guaranteeing the integrity and safety of the stored pharmaceuticals. In conclusion, stainless steel angles unequivocally emerge as a dependable and pragmatic selection for pharmaceutical storage systems.

- Q:What are the fire resistance properties of stainless steel angle?

- The excellent fire resistance of stainless steel angle is attributed to its composition and properties. Unlike other metals like aluminum or carbon steel, stainless steel has a significantly higher melting point. This characteristic makes stainless steel angle highly resistant to heat and fire. In addition, stainless steel exhibits a low thermal conductivity, meaning it does not easily transfer heat. This property further enhances its fire resistance by preventing the transfer of heat from the fire source to the stainless steel angle. This is particularly important in industries where fire protection and structural integrity are crucial, such as construction. Furthermore, stainless steel angle is non-combustible, meaning it does not burn or contribute to the spread of fire. This is because of its corrosion-resistant properties and the presence of a protective oxide layer on its surface. This oxide layer acts as a barrier against heat and oxygen, making stainless steel angle a reliable and safe material choice. In summary, the fire resistance properties of stainless steel angle are highly regarded. It can withstand high temperatures, does not easily conduct heat, and does not burn. These characteristics make stainless steel angle an ideal choice in applications where fire resistance is a top priority.

- Q:What is the yield strength of stainless steel angles?

- The yield strength of stainless steel angles can vary depending on the specific grade of stainless steel being used. Generally, stainless steel angles have a yield strength ranging from 30,000 to 80,000 pounds per square inch (PSI). However, it is important to note that this can vary depending on the specific grade, thickness, and manufacturing process of the stainless steel angle. It is recommended to consult the manufacturer's specifications or a materials engineer for the exact yield strength of a specific stainless steel angle.

- Q:Can stainless steel angles be used in sewage treatment plants?

- Yes, stainless steel angles can be used in sewage treatment plants. Stainless steel is highly resistant to corrosion and can withstand the harsh and corrosive environment found in sewage treatment plants. It is a durable and long-lasting material that can be used for various applications, including structural support and equipment in sewage treatment plants.

- Q:Are stainless steel angles suitable for the production of shelving systems?

- Indeed, stainless steel angles prove to be a fitting choice for the fabrication of shelving systems. Renowned for its durability and resistance to corrosion, stainless steel emerges as an optimal material for deployment in shelving systems that might come into contact with moisture or endure harsh conditions. By furnishing structural reinforcement, stainless steel angles facilitate the creation of sturdy and secure shelving units through effortless welding or bolting. Moreover, stainless steel boasts a sleek and contemporary aesthetic, rendering it a favored option for both industrial and residential shelving systems.

- Q:Can stainless steel angle be used in noise control applications?

- Indeed, noise control applications can certainly incorporate stainless steel angle. Renowned for its exceptional strength and durability, stainless steel proves to be an impeccable choice for implementing effective noise control measures. By utilizing stainless steel angle, one can construct barriers, enclosures, and partitions that effectively diminish noise transmission. Moreover, its corrosion resistance properties render it highly suitable for outdoor noise control applications. Furthermore, the ease with which stainless steel angle can be fabricated and installed enables the creation of tailored noise control solutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords