High Speed Trapezoidal sheets Roll Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Trapezoidal sheets Roll Forming Machine

Technical data of Trapezoidal sheets Roll Forming Machine

Suitable Material | Q235 color steel sheet;0.3-0.7mm, 1000&1250mm coil width | |

Working speed | About 20m/min | |

Power Requirement | Main motor power: 7.5 Kw(Depend on final design) | |

Hydraulic station power: 2.2Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 8500KGS | |

Machine''''s size | About 15m×1.8m× 1.5m (Depend on final design) | |

Shipping | 1x40GP container can load one machine | |

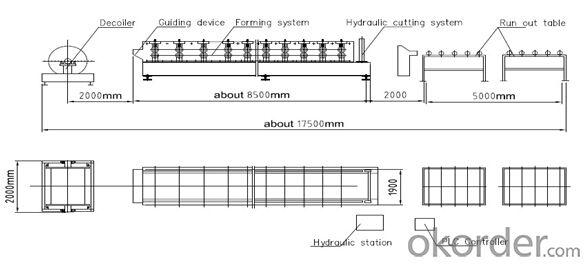

Layout drawing of Trapezoidal sheets roll forming machine

Our Trapezoidal sheets Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q:How many kinds of machine tools

- Point-by-point control The CNC machine is characterized by the fact that the moving parts of the machine can only realize the precise movement from one position to another, and do not carry out any processing in the course of movement

- Q:What is the instrument lathe, how to use it?

- The instrument lathe adopts spring chuck fast clamping, the motor directly drives the spindle, the size of the disc fast hand-operated operation, the vertical and horizontal positioning control turning, part of the instrument lathe is equipped with flange, tailstock device, mold clamping machine,

- Q:Machine operating procedures

- 3, check the table, rail and the main sliding surface with or without new pull, research, bumps, if the team should be informed of the team leader or equipment to view and make a record;

- Q:What lathes are lathes?

- Jiangsu Branch Knight Electrical and Mechanical Equipment Co., Ltd. (formerly Suzhou Zhen Ye Electrical and Mechanical Equipment Co., Ltd.)

- Q:The basic structure and function of machine tools

- 1, supporting parts for the installation and support of other parts and workpieces, to withstand its weight and cutting force, such as bed and pillars;

- Q:What is the machine?

- Generally divided into metal cutting machine tools, forging machine tools and woodworking machine tools.

- Q:Lathe C6140 meaning

- The meaning of the first digit of the lathe, 0 for instrument lathe, 1 for single-axis automatic lathe, 2 for multi-axis automatic semi-automatic lathe, 3 for hexagonal lathe, 4 for crankshaft and camshaft lathe, 5 for vertical lathe,

- Q:What are the types of machine tools?

- Punch: The table is fixed and the slider is for reciprocating straight motion.

- Q:Compared with ordinary machine tools, how to look at the inevitable emergence of CNC machine tools

- Third, the surface requirements for some complex surface, with ordinary machine is difficult or can not be processed at all, must use CNC machine tools to find through the bit to achieve.

- Q:How about CNC machine tools

- Hello, nice to be able to answer your question

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Speed Trapezoidal sheets Roll Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches