High quality alcohol stainless fermentation tank

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Fermentation tank

Our factory supplies manufacturing various stainless steel tanks with orwithout jacket, agitation etc.

1.Specifications

1)Materials: SUS304, SUS316.

2) Design Tem: asper design

3)Design P: as perdesign

4)Capacity:as per design

5)Manufacture standard: ASME GB/T

6)Design service:provided

7)After-salesservice: provided

8)Service life:fifteen years

2. Our products contain 5 assortments :

1)chemicalsassortments(ethanol,methanol,furfuraldehyde,etc.)

2) food assortments,

3) dairy assortments,

4) pharmaceutical assortments,

5) beverage assortments.

3. Here is the main products of stainless steel tanks:

1) Water tank,

2)storage tank,

3)prcoess tank,

4)beer tank,

5)dairy tank,

6)reactor tank,

7)fermenting tank,

8)vacuum tank,

9)any style of tank made of stainless steel ,platform,worktable,goodsshelf,wheel car,tank car,whatever made of stainless steel products.

If you have any interested in our products please contact me feel free.

2.New Technology Description:

Five-Column Three-Effect Distillation Process

Our company designs and manufactures latestFive-Column Three-Effect Distillation equipment.This new process is promoted on the basis of traditional five-column differential-pressure column and mainly used for super-fine alcohol production.

The key of this process is the heating methods,the steam heats one column directly and transfers theheat to other 4 columnsto achieve three-effect thermal coupling and energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing of circulating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table Of Five-Column

Three-Effect Distillation Process for Super-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

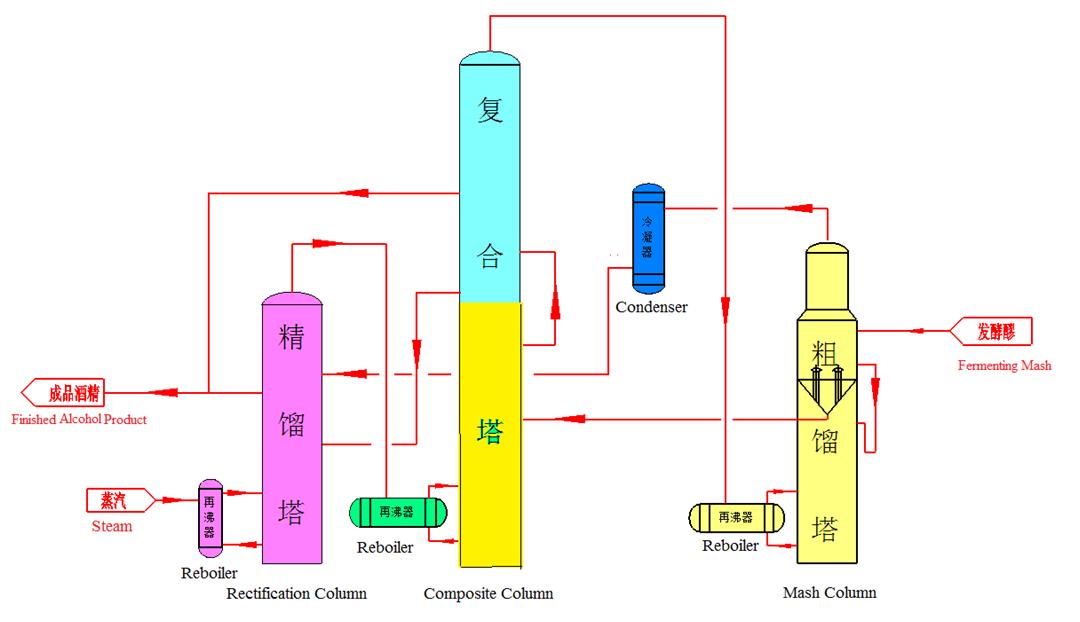

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production of general-grade alcohol& fuel ethanol, and it was awarded Chinese national patent, it is the onlysuccessfulapplicationof double mash column & three-effect in the world,which produces general-grade alcohol.

This process is composed by mash column, rectification column and composite column. The composite column functions as mash column and rectification column.

The key of this process is the heating methods: the steam heats one column directly and transfers the heat to other 2 columns to achieve three-effect thermal coupling and energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) in a month.

3. Among 16 production workshops,3 workshops are for mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshops are for assembling & welding.

4. We own advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3). Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification

1).Our company can provide a sophisticated product after-sale service and can ensure the implementation, maintenance and commission of projects.

2). We can reach the project site after receiving the user’s notification.

6.Package & Transport

Our company can package the products according to enterprise export standard, and use container or bulk transport.

- Q:The pressure vessel Often see separator, water casing furnace, cent gas bag and so on to be marked: capacity 2MS 2LS 1LS

- Pressure vessel standards means: according to the requirements of the pressure vessel product technology to control and supervision of pressure vessel design, manufacture and inspection of each link, ensure the quality of the product and the safe use of a standard. Pressure vessel status: integration of international standards With the gradual development of global economic integration, the trend of internationalization of the pressure vessel is more and more obvious. Standard globalization is an irreversible trend, in this case, our country should actively participate in the international standard formulation work, timely understanding of new dynamic, study the corresponding countermeasure and the principle of the standard of our country, with the actual situation in our country proposals and Suggestions, or pressure vessel industry in China will participate in participating in international competition.

- Q:What is called pressure vessel?

- To differs from general containers (pressure vessels), only the container at the same time satisfy the following three conditions, pressure vessel is called: (1) the maximum working pressure (Pw) (note 1) greater than or equal to 0.1 Mpa (excluding hydrostatic pressure, the same below); (2) the internal diameter (section refers to its maximum size, shape) is greater than or equal to 0.15 m, and the volume (V) (note 2) greater than or equal to 0.25 m3. (3) loading medium for liquefied gas or highest working temperature is higher than equal to the standard boiling point liquid.

- Q:How much force is inside the pressure vessel

- In an instant, the pressure inside the container is less than the atmospheric pressure, and the vessel is subjected to external pressure, which is unstable

- Q:Does the starting pressure of the pressure vessel relief valve be equal to the design pressure of the container?

- The opening pressure of the relief valve is less than or equal to the design pressure.

- Q:Is a lithium bromide unit a pressure vessel?

- Lithium bromide unit steam type, warm water type, direct combustion type etc. The direct-fired lithiumbromide refrigerator is not a pressure vessel. Steam drive of heat steam pressure more than 2 kg regenerator are subject to pressure vessel, warm water type water driving heat source temperature greater than 130 degrees of above commonly, regenerator according to pressure vessel design.

- Q:What are the measures to prevent the burning of flammable media in pressure vessels

- Intense combustion occurs in a limited space where there is an explosion, there are three factors, combustible, sufficient oxygen, limited airtight space, so your problem doesn't necessarily explode.

- Q:The burner (not the boiler) is the pressure vessel

- Is, of course. The pressure container is defined as follows: (1) working pressure (note 1) greater than or equal to 0.1 Mpa (work pressure refers to the pressure vessels under normal working condition, the top can reach the highest pressure (pressure)); (no liquid static pressure) (2) the diameter of the inner diameter (for the non-circular section, the width of the width of the diagonal, or the diagonal of the diagonal) is not less than 150mm (3) the working medium is a liquid which is above the standard boiling point for gas, liquefied gas or temperature

- Q:Company into a tube and shell heat exchanger, working pressure is 3 kilograms, can according to the provisions of the customs formalities for tax exemption, but customs has a regulation: high pressure vessel cannot do duty-free, now I can provide the customs requirements 3 kilograms of pressure for high pressure of national standard, which is the national standard, please?

- TSG R0004-2009 type pressure vessel safety technology and supervision code Annex A The design of the pressure vessel pressure (p) is divided into low pressure, medium pressure, high pressure and ultrahigh pressure of four classes: (1) low pressure: L code, 0.1 MPa acuities were p < 1.6 MPa (2) the intermediate pressure: M code, 1.6 MPa acuities were p < 10.0 MPa (3) high pressure: code H, 10.0 MPa acuities were p < 100.0 MPa (4) the ultrahigh pressure: code U, p p 100.0 MPa Note: (1 kg pressure equal to 0.1 MPa) checked our design can know is that level

- Q:The highest pressure is greater than or equal to how much mpa referred to as pressure vessels

- To differs from general containers (pressure vessels), only the container at the same time satisfy the following three conditions, pressure vessel is called: (1) pressure (note 1) greater than or equal to 0.1 Mpa (work pressure refers to the pressure vessels under normal working condition, the top can reach the highest pressure (pressure)); (excluding hydrostatic pressure) (2) the internal diameter (non circular cross section refers to its maximum size) is greater than or equal to 0.15 m. And volume (V) is greater than or equal to 0.025 cubic meters, the product of working pressure and volume greater than or equal to 2.5 MPa -l (volume, refers to the geometric volume of the pressure vessel). (3) loading medium for gas, liquefied gas and highest working temperature is higher than or equal to its standard boiling point of the liquid.

- Q:The classification of the pressure vessel???

- TSG R0004-2009 "stationary pressure vessels safety and technical supervision regulation in the annex A detailed instructions are included on the classification of the pressure vessel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High quality alcohol stainless fermentation tank

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords