Grade 304_304L Stainless Steel Flat Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade 304_304L Stainless Steel Flat Bar with High Quality

Details of Grade 304_304L Stainless Steel Flat Bar with High Quality

Name | 200,300,400 series Stainless Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | 201/304/304L/309L/316/321 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 3mm-12mm |

steel flat bar width | 19mm-140mm |

steel flat bar length | 2m~6m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Chemical Composition of Grade 304_304L Stainless Steel Flat Bar with High Quality

Grade and Main chemical composition% | |||||||||

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other |

201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

304L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 13-Sep | - |

309S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | - | 15-Dec | - |

316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 3-Feb | 14-Oct | - |

321 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 13-Sep | Ti≥5×C |

CNBM Introduction of Grade 304_304L Stainless Steel Flat Bar with High Quality

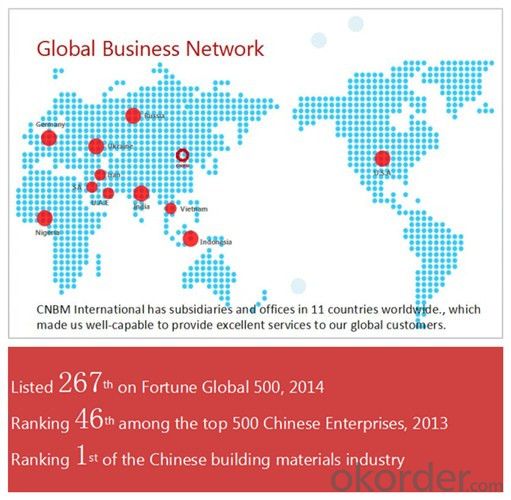

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Grade 304_304L Stainless Steel Flat Bar with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:How do I choose the right size of steel flat bar for my project?

- To choose the right size of steel flat bar for your project, you should consider factors such as the load-bearing capacity required, the dimensions of the project, and any specific design requirements. It is essential to consult with a structural engineer or an expert in steel fabrication to ensure that the chosen size can adequately support the intended weight and meet the project's specifications.

- Q:Can steel flat bars be used for making HVAC systems or components?

- Yes, steel flat bars can be used for making HVAC systems or components. Steel is a common material used in the HVAC industry due to its strength, durability, and resistance to corrosion. Steel flat bars can be fabricated and shaped to create various components such as support brackets, frames, or ductwork for HVAC systems.

- Q:Can steel flat bars be used for manufacturing machinery or equipment?

- Yes, steel flat bars can be used for manufacturing machinery or equipment. They are commonly used in construction, automotive, and manufacturing industries to create structural components, frames, supports, and various machine parts due to their strength, durability, and versatility.

- Q:How do you determine the load capacity of a steel flat bar?

- To determine the load capacity of a steel flat bar, you need to consider factors such as the dimensions and material properties of the bar, the type of loading it will experience, and the desired safety factor. Calculations involving formulas and engineering principles can be used to determine the maximum load the flat bar can withstand without experiencing permanent deformation or failure.

- Q:What is the tensile strength of a steel flat bar?

- The specific grade and manufacturing process of a steel flat bar can cause variations in its tensile strength. However, steel flat bars are generally well-known for their high tensile strength. Tensile strength refers to the maximum amount of tensile stress a material can endure before breaking or failing. Typically, steel flat bars are made of carbon steel, which possesses a high tensile strength. The exact tensile strength can differ, but it typically falls within the range of 400 to 700 megapascals (MPa). It is important to consider that the thickness and width of the flat bar, as well as any additional heat treatment or alloying elements in the steel, can also affect the tensile strength. For precise and accurate values of tensile strength, it is advisable to consult the specific grade and manufacturer's specifications.

- Q:What are the different types of coatings available for steel flat bars?

- There are several different types of coatings available for steel flat bars, each offering unique properties and advantages. 1. Galvanized Coating: This is one of the most common types of coatings for steel flat bars. It involves applying a layer of zinc to the surface of the steel, which provides excellent corrosion resistance. Galvanized coatings are durable and can withstand harsh environments, making them suitable for outdoor applications. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the steel flat bar, which is then cured under heat to form a protective layer. This coating offers excellent durability, resistance to chipping, and a wide range of color options. Powder coatings are often used for decorative purposes or in applications where a durable and aesthetic finish is desired. 3. Epoxy Coating: Epoxy coatings are a popular choice for steel flat bars that will be exposed to corrosive environments. These coatings are applied as a liquid and then cured to form a hard, protective layer. Epoxy coatings provide excellent chemical resistance and can withstand exposure to acids, alkalis, and other corrosive substances. 4. Paint Coating: Paint coatings are a versatile option for steel flat bars, offering both protection and aesthetics. These coatings can be applied in various colors and finishes, providing a decorative and protective layer. Paint coatings may require periodic maintenance and touch-ups to maintain their effectiveness. 5. Anodizing: Anodizing is a process primarily used for aluminum but can also be applied to steel flat bars. It involves creating an oxide layer on the surface of the metal, which enhances its corrosion resistance and provides an attractive finish. Anodized coatings are particularly suitable for architectural and decorative applications. 6. Phosphate Coating: Phosphate coatings are a type of conversion coating that chemically reacts with the steel surface to form a protective layer. These coatings offer excellent adhesion, corrosion resistance, and improved paint adhesion. Phosphate coatings are commonly used as a pre-treatment before the application of paint or powder coatings. In conclusion, the different types of coatings available for steel flat bars include galvanized coatings, powder coatings, epoxy coatings, paint coatings, anodizing, and phosphate coatings. The choice of coating depends on the specific requirements of the application, such as corrosion resistance, durability, aesthetics, and environmental conditions.

- Q:Are steel flat bars suitable for making frames or supports?

- Yes, steel flat bars are often suitable for making frames or supports. Steel is known for its strength and durability, making it a popular choice for constructing various structures. Steel flat bars provide a sturdy base and can be easily welded or bolted together to form frames or supports. They are commonly used in industries such as construction, manufacturing, and engineering, where robust structures are required. Additionally, steel flat bars can be customized to specific dimensions and shapes, allowing for flexibility in design. Overall, steel flat bars are a reliable and suitable choice for making frames or supports due to their strength, durability, and versatility.

- Q:Can steel flat bars be used for manufacturing architectural facades or cladding?

- Yes, steel flat bars can be used for manufacturing architectural facades or cladding. They offer strength, durability, and a sleek appearance, making them suitable for such applications. Additionally, steel flat bars can be easily fabricated and installed, making them a popular choice in architectural design.

- Q:How do you prevent distortion or warping on steel flat bars during machining?

- To prevent distortion or warping on steel flat bars during machining, several measures can be taken. Firstly, proper clamping techniques should be employed to securely hold the flat bars in place and minimize movement during machining. Additionally, using appropriate cutting speeds and feeds, as well as employing coolant or lubricants, can help dissipate heat and reduce the risk of warping. It is also essential to ensure that the machining process is carried out with stable and consistent cutting forces to avoid excessive stress on the material. Finally, post-machining stress-relieving treatments, such as annealing or tempering, can be applied to minimize residual stresses and further prevent distortion or warping.

- Q:Can steel flat bars be used in the construction of bridges?

- Yes, steel flat bars can be used in the construction of bridges. Steel flat bars are commonly used in bridge construction as they provide strength, durability, and stability. They are often utilized in the fabrication of bridge components such as beams, trusses, and supports. Additionally, steel flat bars can be easily welded, making them versatile and suitable for various bridge designs and construction requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade 304_304L Stainless Steel Flat Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords