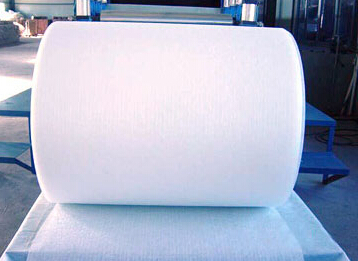

FRP Surfacing Mat- high qulity, low price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

It is mainly used in the surface layers of FRP products. It is characterized by uniform fiber dispersion, smooth surface, soft hand-feeling, low binder content, fast resin impregnation and good mould obedience.

This line of product falls into two categories: Wrap type \series and hand lay-up type series. The wrap type FRP surfacing mat is most suitable for wrapping FRP pipes and vessels because it is capable of significantly to improve the performances of surface layer to realize longer lifetime and resistance against corrosion leakage and compression.

The hand lay-up type FRP surfacing mat is especially suitable for molding with sophisticated contours while it is characterized by its good mould obedience and fast resin penetration. It is an indispensable material for high quality moulds and FRP products as it is capable of covering up the texture of underlayer to create high gloss surface that gives rise to improved strength and corrosion resistance. The surfacing mats in these two categories are also applicable to other FRP molding processes such as press moulding, spray-up, centrifugal rotating moulding, etc.

- Q:What are the characteristics of the external insulation materials Mesh?

- 1. The good chemical stability. Alkali resistance, acid resistance, water proofing, erosion-resistant cement, and other chemical corrosion resistance; It is with strong bonding resin and easy to be soluble in styrene. 2. The high strength, high modulus, and light weight. 3. With a good dimensional stability, stiffness, smooth, easy to shrinkage deformation, and targeting resistance. 4. The good impact resistance. (Due to the high strength of the mesh and its good toughness) 5. The anti-mildew ability and insect?prevention ability. 6. The fire protection, thermal insulation, sound insulation, insulation.

- Q:what's the thermal insulation effect of the self-adhesion thermal insulation reflection of light aluminium foil glass fiber fabric mesh.

- However, aluminum foil and heat insulation cloth fabric is good in general, the aluminum foil is mainly to solve the radiant heat, with the use of the cotton to reach the best effect.

- Q:The difference between wet and dry gridding cloth for external wall thermal insulation

- There is no obvious difference between them except bottom ash and material amount.

- Q:How to distinguish warp?and?weft of alkali-resistant fiberglass mesh?

- Warp is the two strands of winding small wire.

- Q:Air purifier filter, activated carbon or glass fiber good?

- The HEPA screen made of glass fiber is generally accepted to achieve high efficiency. Because of the high requirement of glass fiber in making technology, the quality of products is low.

- Q:Is it necessary to add 2 times of alkali resistant fiberglass mesh on the first floor?

- 1. glass fiber mesh cloth is the worst market price is usually around 1 yuan -1.60, glass fiber is usually made of clay crucible drawing glass beer bottle some kind of waste? Forbidden state in the production process, the surface coating resistant to alkali emulsion. Intuitively: rough sales of more general market theory, often not long enough the weight is less than 2 times, with no sound easy to shift, easy to hurt the skin. This type of network is used in the insulation layer is generally two months after losing power, if the mortar net downed just gently removed, grinding, glass fiber yarn into powder.

- Q:When the wall plastering, can use galvanized steel mesh instead of alkali glass fiber mesh cloth?

- Galvanized steel net is generally used in cement mortar plastering stage wall plastering, when the total thickness of greater than or equal to 35mm, use galvanized steel net, to prevent the powder layer cracking, and in the decoration stage wall putty is used with glass fiber mesh to prevent surface putty layer cracking.

- Q:What is the standard of external wall thermal insulation mesh?

- Current national external walls thermal insulation mesh technical standards (JG): The glass grid warp-wise and weft alkali resistant tensile breaking strength are not less than 750N / 50mm, the retention?rate of alkali resistanttensile fracture strength is not less than 50%, the weight of per square meter ≥130 grams. The JG glass grid warp-wise and weft alkali resistant tensile breaking strength are not less than 1250N / 50mm, the retention?rate of alkali resistant tensile fracture strength is not less than 90%, the weight of per square meter ≥160 grams. The retention?rate of breaking strength and alkali-resistant strength: It is generally known that breaking strength and alkali-resistant strength retention rate is an important performance of fiberglass mesh. Breaking strength is inseparable to the count or weight of glass fiber. Fiberglass mesh for exterior outer insulation systems is generally about 130 grams per square meter on the current market, intensity is generally low, if you want to achieve this requirement, the weight should be more than 160 grams per square meter. Standard mesh with good quality is based on the platinum glass?fiber, both in the selection of materials and weaving processes are more exquisite. Coating emulsions have good alkali resistance. Excellent alkali resistance and high warp and weft tensile strength make the product has a good feeling and good construction fitting, to a large extent, reduce the amount of plastering mortar.

- Q:What role does exterior wall thermal insulation mesh cloth play?

- Wall mesh, also called glass fiber wall mesh, with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into.

- Q:What are the types of glass fiber gridding cloth?

- Specifications for gridding cloth for external walls: 70-160/g. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is used for strengthening cement plaster wall.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Surfacing Mat- high qulity, low price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords